The TJU Racing Team(Tongji University Racing Team) successfully announced their new racing car model, the TR21, at the 2021 New Car Model Public Announcement on October 12, 2021, in the 101 Lecture Hall of Jiren Building, Jiading Campus.

Polymaker participated in the event as one of the sponsors, and Cui Yue, a professional racer in the Porsche Carrera Cup Asia, was invited to drive the TR21.

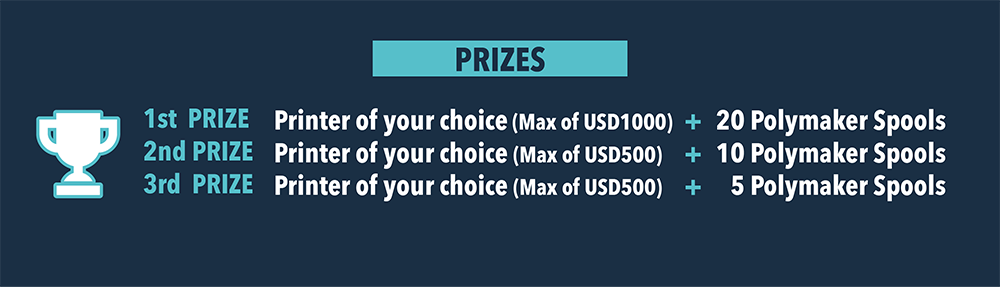

Picture 1 | Polymaker Attended the 2021 New Car Model Public Announcement of TJU Racing Team

The TR21 is the 14th racing car independently designed and manufactured by the TJU Racing Team. The new model achieves significant innovations over previous models, oftentimes by using Polymaker’s 3D printing materials.

Picture 2 | Picture Stripes of TR21 Public Announcement

Strong Power Core

With the Triumph 675 3-cylinder engine as its power core, the TR21 uses a dry lubrication system, dual-cycle cooling system, and a more stable fuel supply system. The model is also equipped with a pure titanium exhaust muffler and hollow titanium alloy half-axles to reduce weight more efficiently. Having the power core and newly developed variable intake system work together heightens the performance of each part even further.

New Body Structure

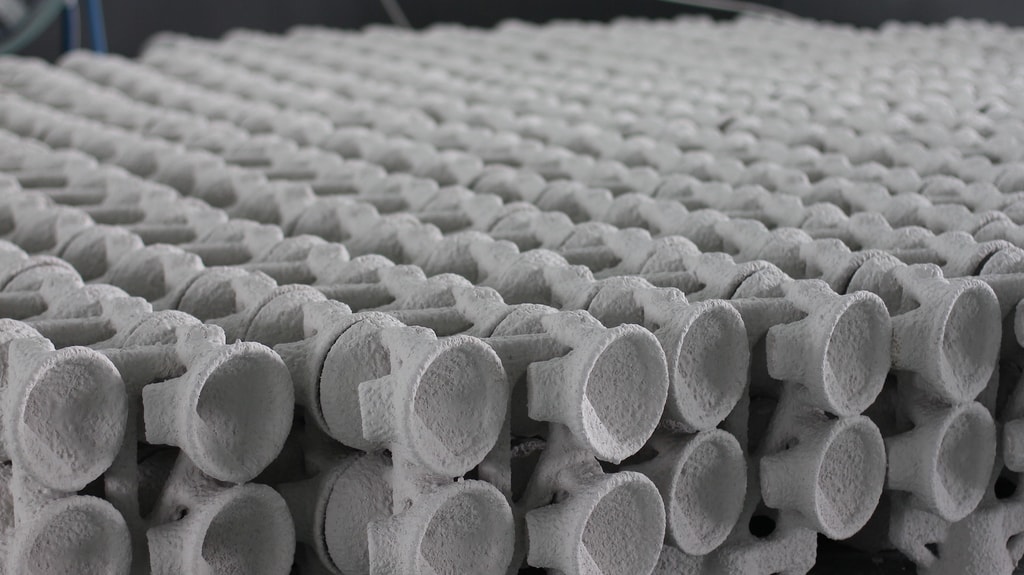

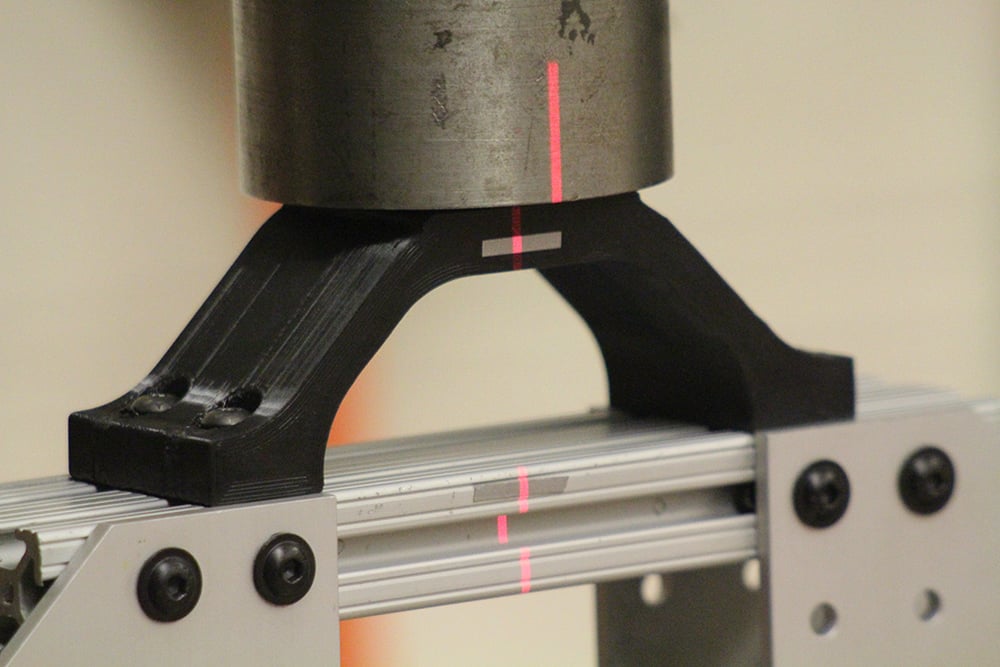

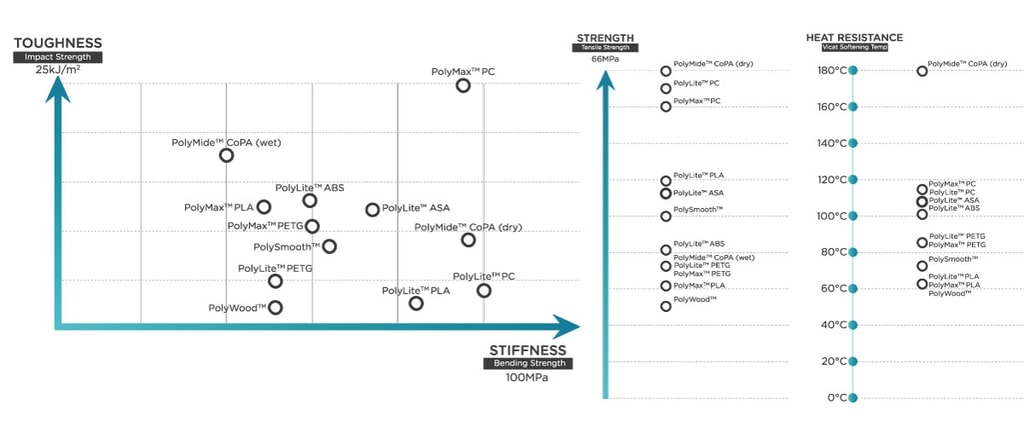

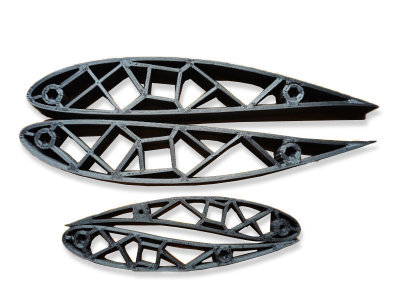

The TR21 adopts the body structure of a full monocoque, replacing the former structure of a mono-frame. The carbon fiber layer, aluminum honeycomb panels, and PMI foam are used to provide higher strength and torsional stiffness while also keeping the body lightweight to ensure ideal weight distribution. Key parts of the body, like monocoque inserts and aerodynamic wing ribs, use PolyMide™ CoPA from Polymaker as the base material to give the parts structural stiffness.

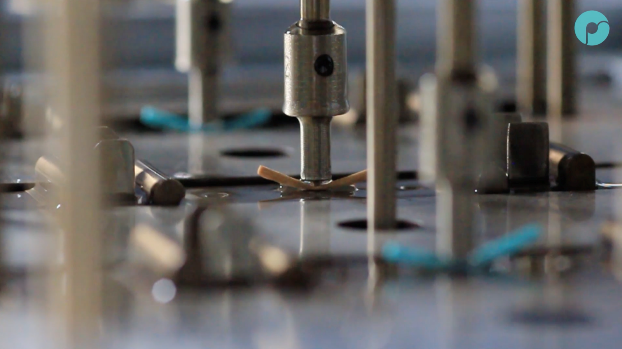

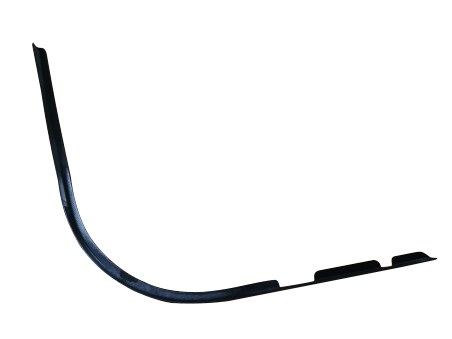

Picture 3 | 3D-printed Front Wing Rib using PolyMide™ CoPA

Picture 3 | 3D-printed Front Wing Rib using PolyMide™ CoPA

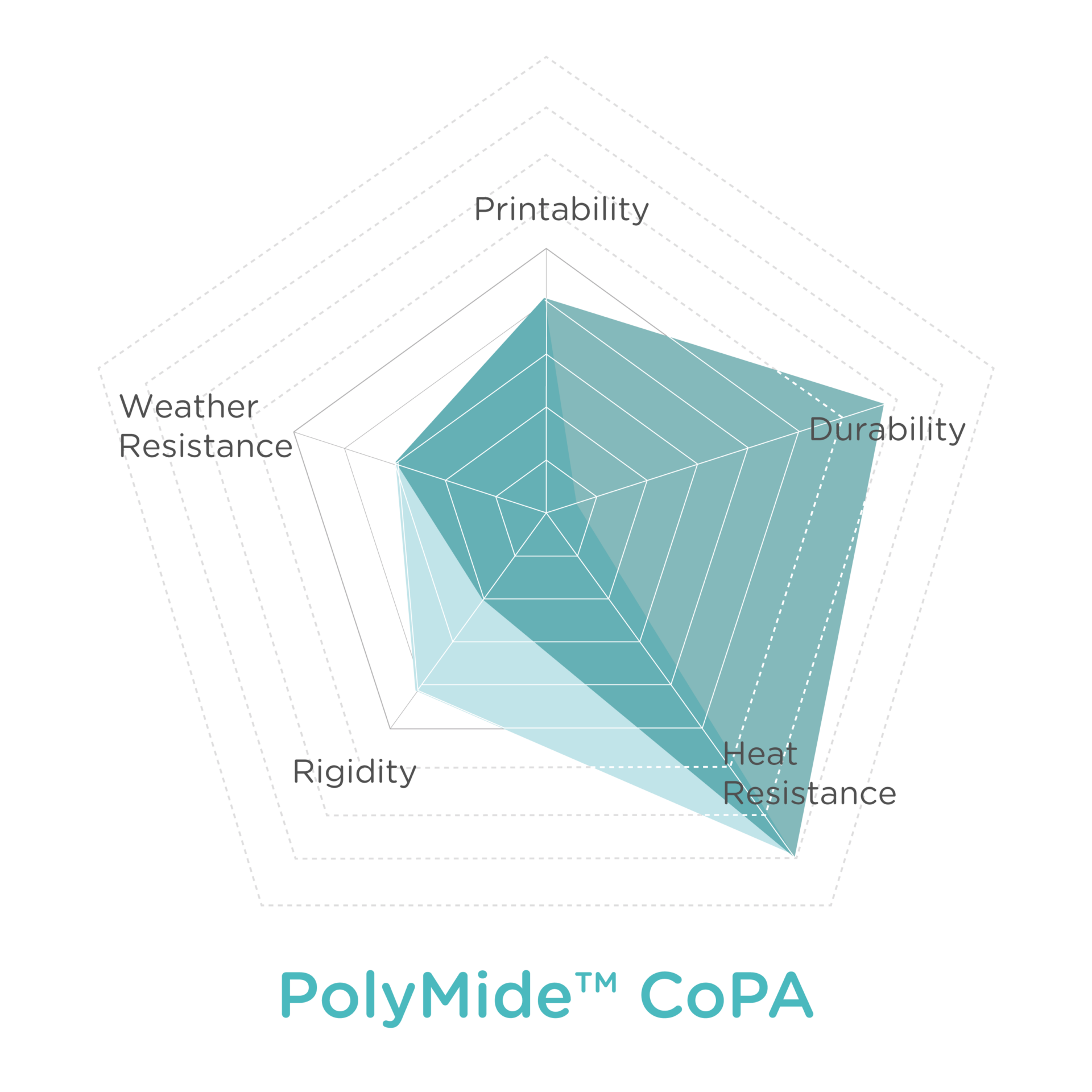

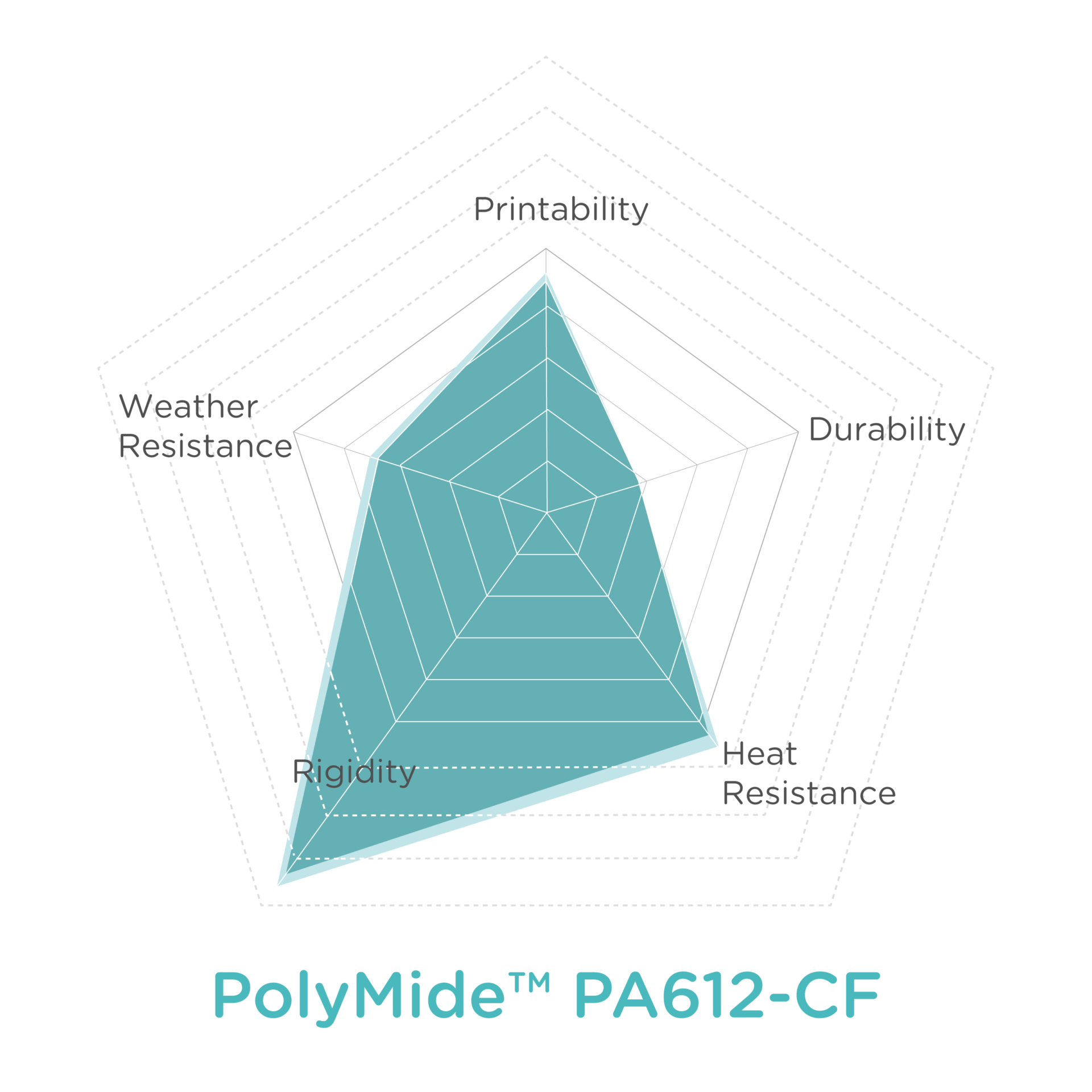

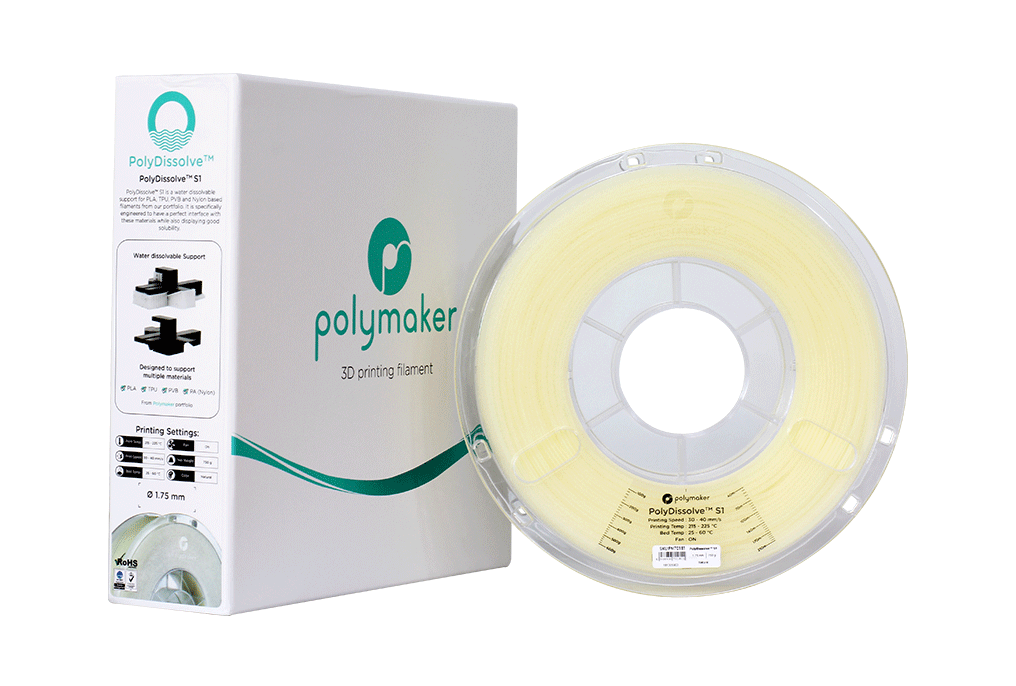

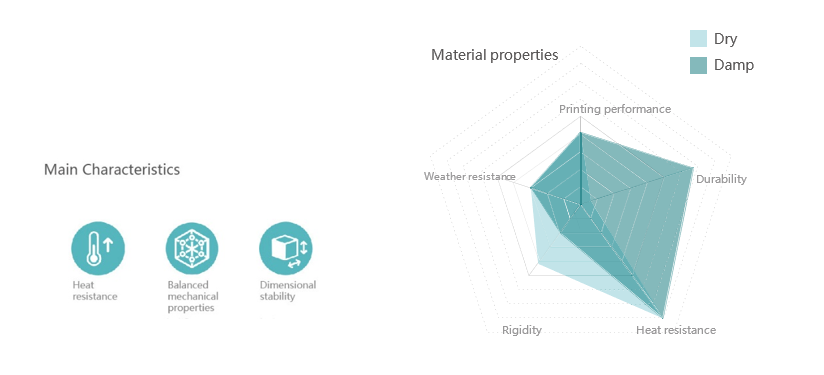

The PolyMide™ product series are 3D printing filaments developed from Nylon. By adopting Polymaker’s patented Warp-Free™ technology, PolyMide™ products not only have the same engineering performance as typical Nylon materials but are also easy to print with a minimum size limit. PolyMide™ CoPA was developed from a copolymer of Nylon-6 and Nylon-6,6, a material with balanced mechanical strength and toughness. Along with the good printability, this material gives dimensional stability with its temperature resistance up to 180˚C, making PolyMide™ CoPA an ideal material for parts like gears, engine mounts, pipe connectors, and high-speed airflow pipes that are used in harsh environments.

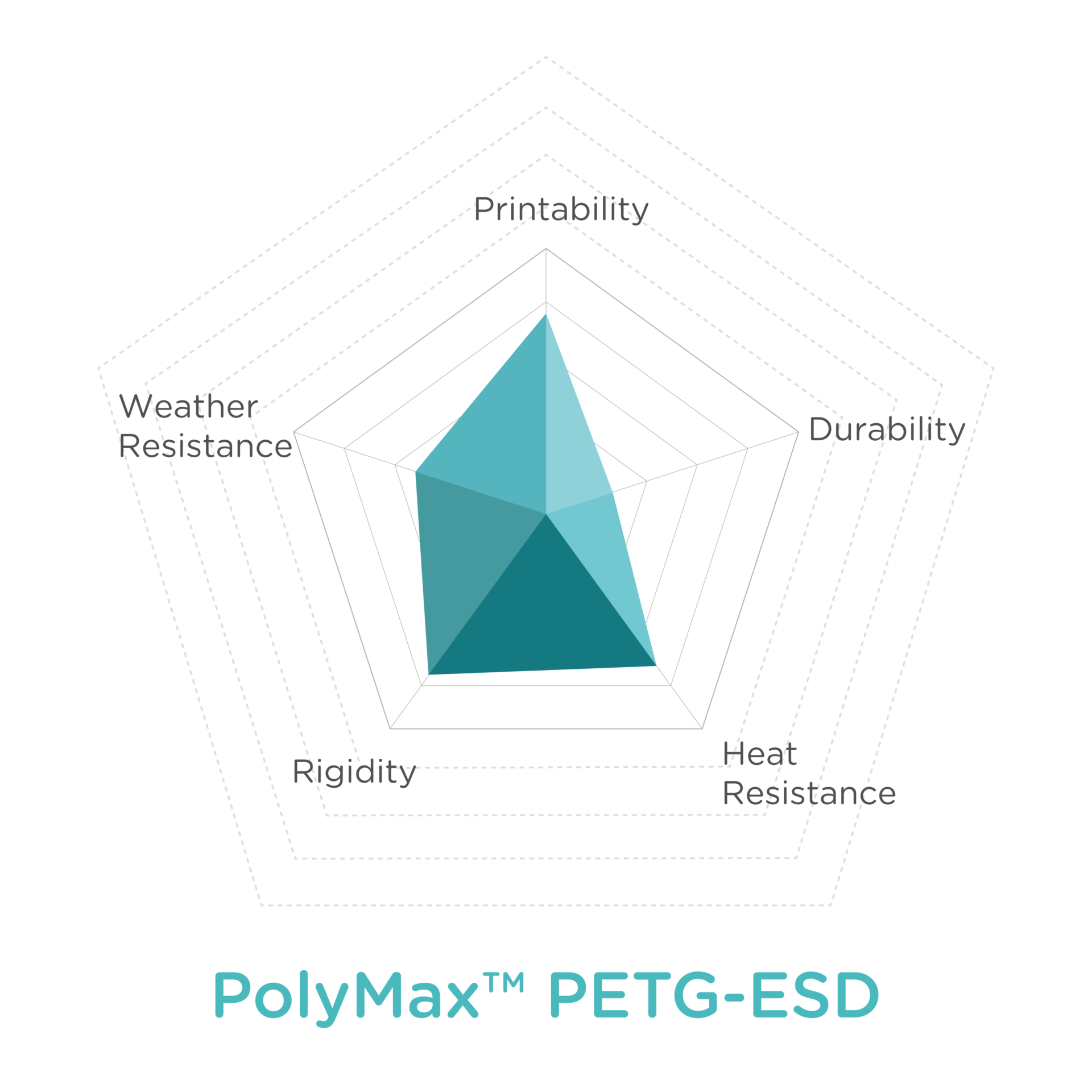

Picture 4 | Main Characteristics and Material Properties of PolyMide™ CoPA

Innovative Aerodynamic Devices Design

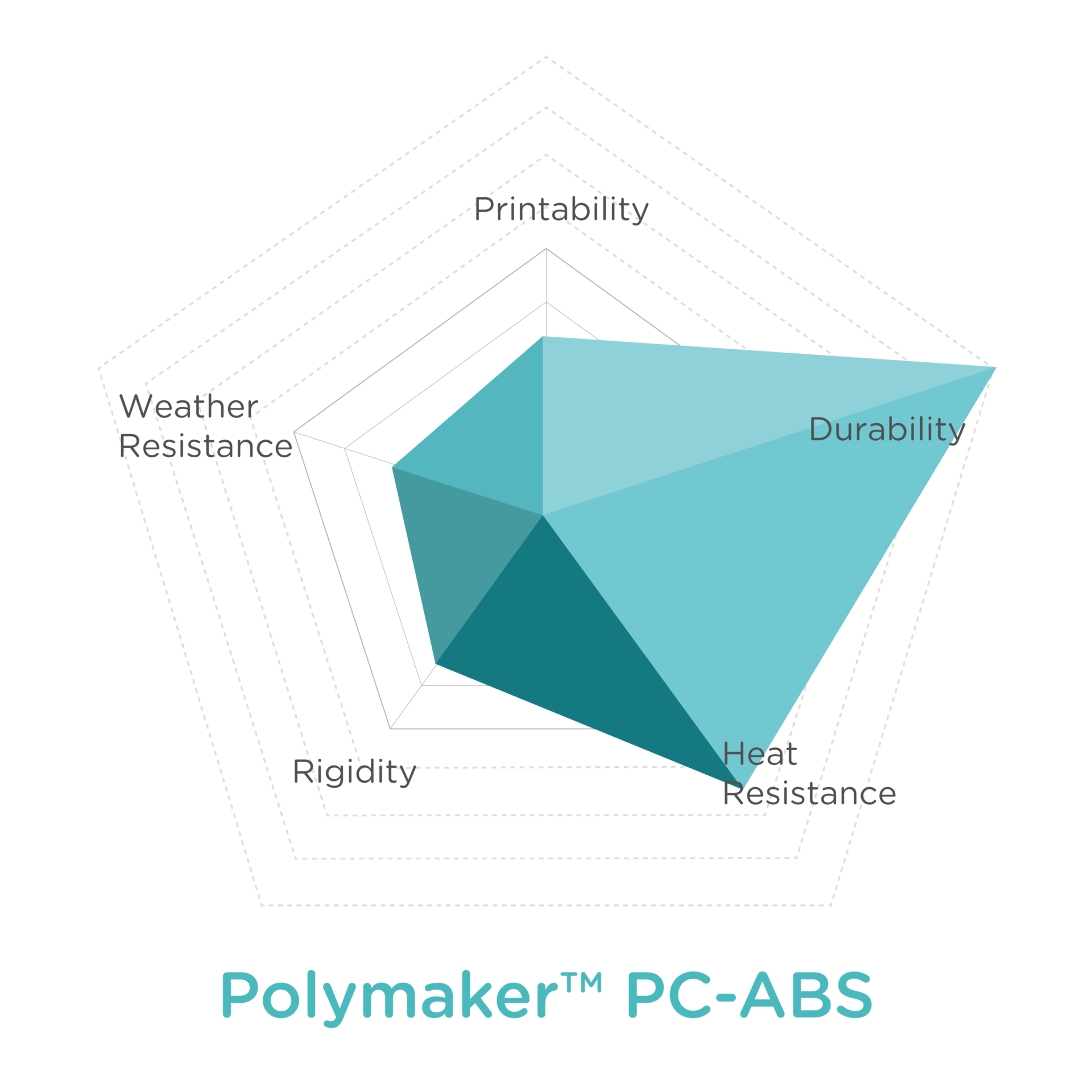

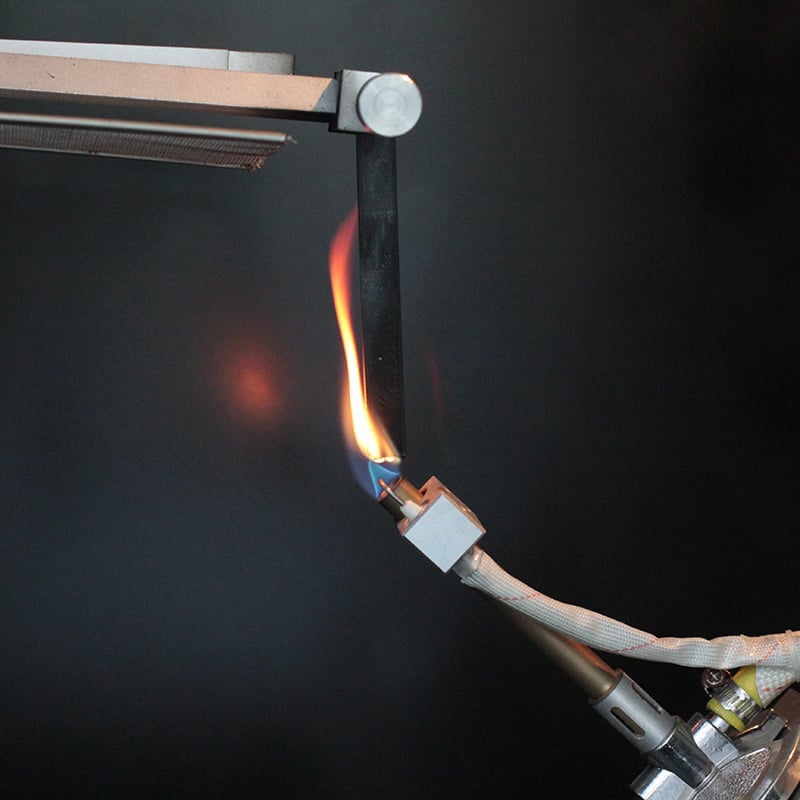

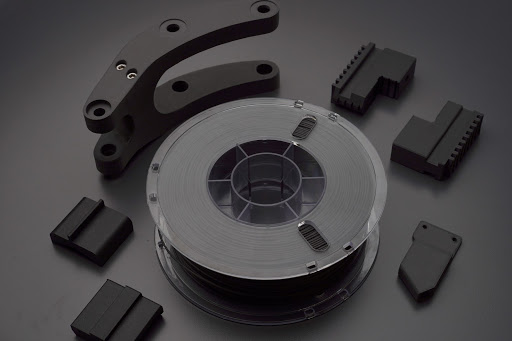

The upgraded body and aerodynamic devices of the TR21 are some of its biggest highlights. Aerodynamics, which dominates the car’s design, has always been the ultimate goal for the TJU Racing Team. After observing systematic design processes and multiphysics simulations, the new aerodynamic devices is able to reach a down force of up to 1075N at the speed of 20m/s, improving the car’s external flow and aerodynamic sensitivity while significantly enhancing its curve speed. The flow deflector in the aerodynamic devices was 3D printed using Polymaker’s PolyMax™ PC material. Not only did the 3D printing material increase the car’s aerodynamic performance, but it also greatly reduced the cost and hours required to produce the flow deflector, with the only sacrifice being structural weight.

Picture 5 | 3D-printed Tail Deflector Using Polymaker PolyMax™ PC

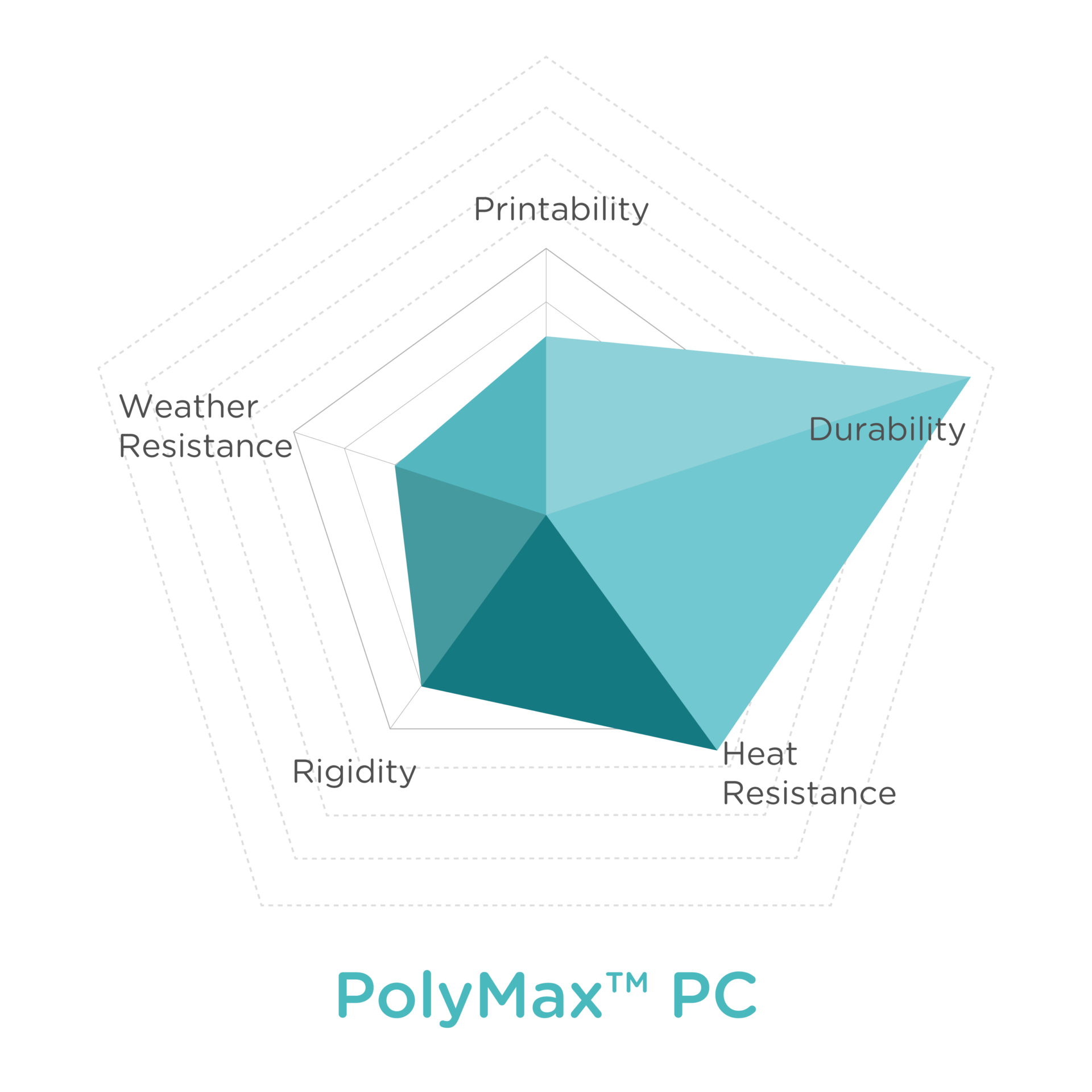

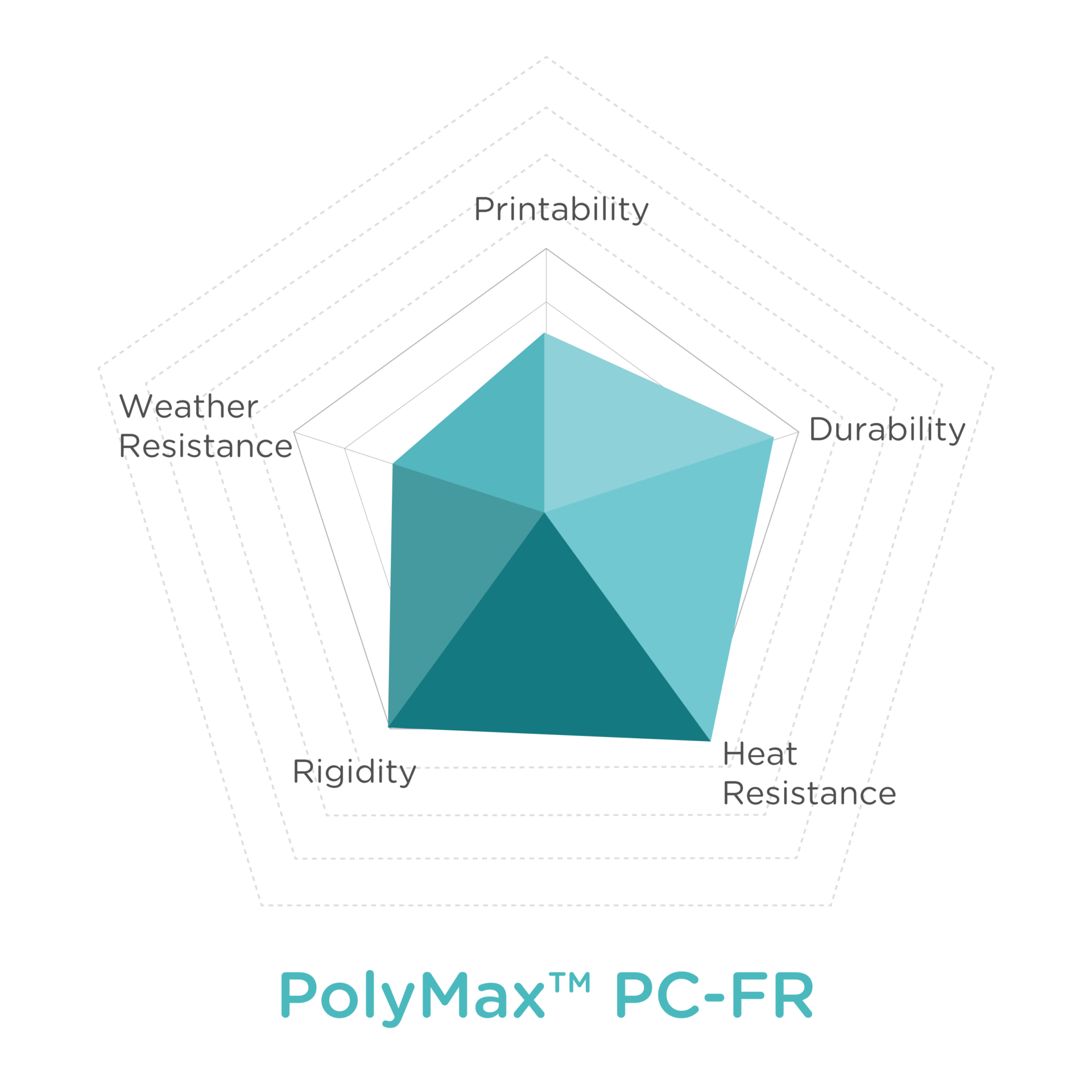

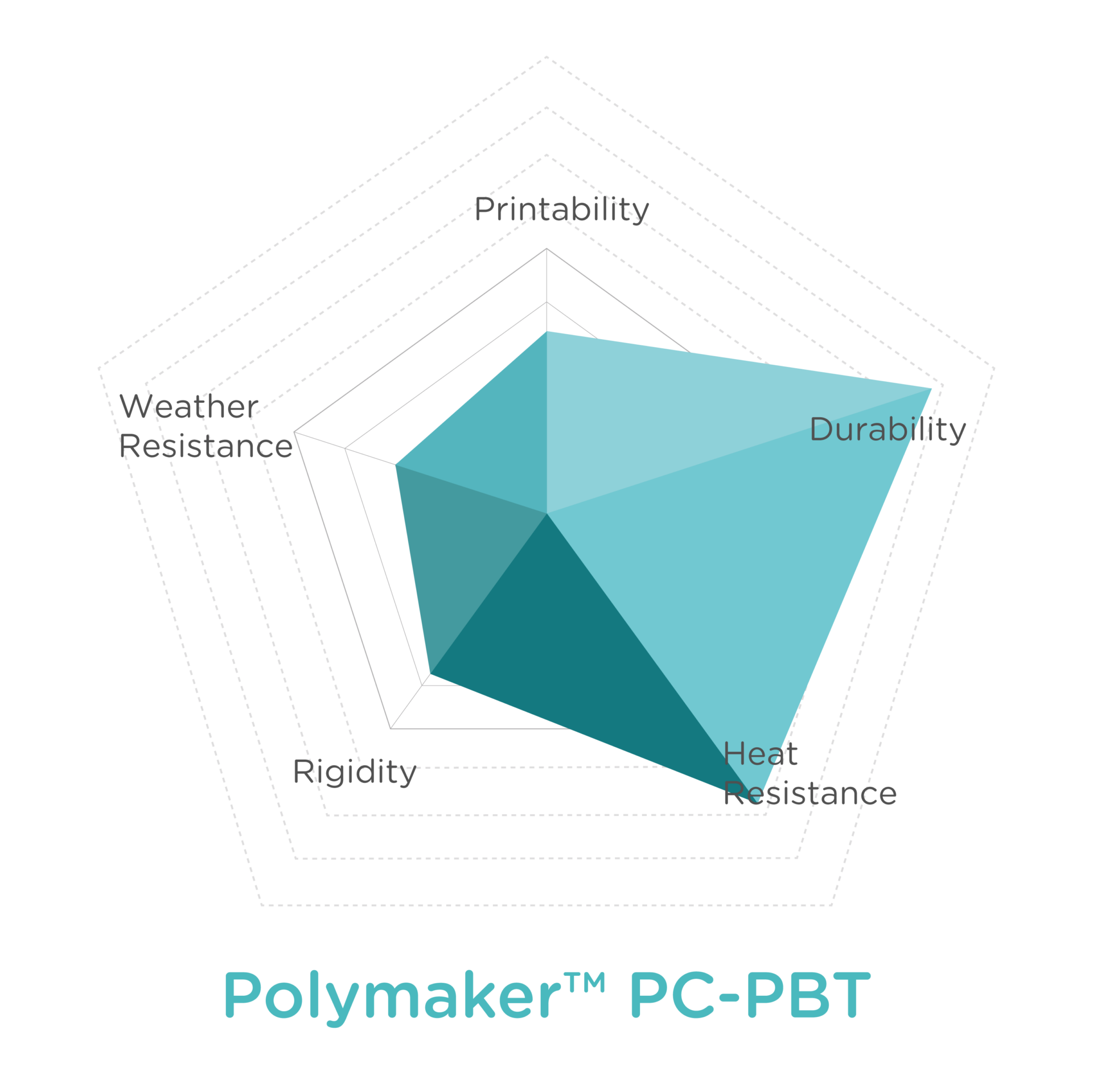

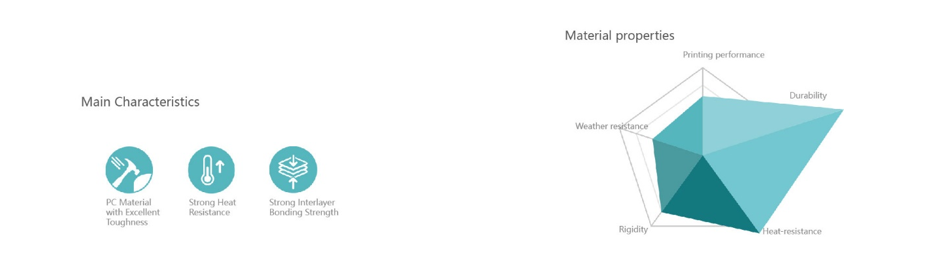

The PolyMax™ product series are advanced 3D printing filaments produced by Polymaker’s patented Nano-Reinforcement technology, all of which have excellent mechanical properties and printing quality. PolyMax™ PC is a high-performance, polycarbonate-based filament boasting strength, toughness, heat resistance, and printing quality, lending itself to engineering applications, specifically when higher resistance for impact and vibration is needed, like in fixtures and fixing tools, furniture, small motor mounts, UAV, 3D printer parts, etc.

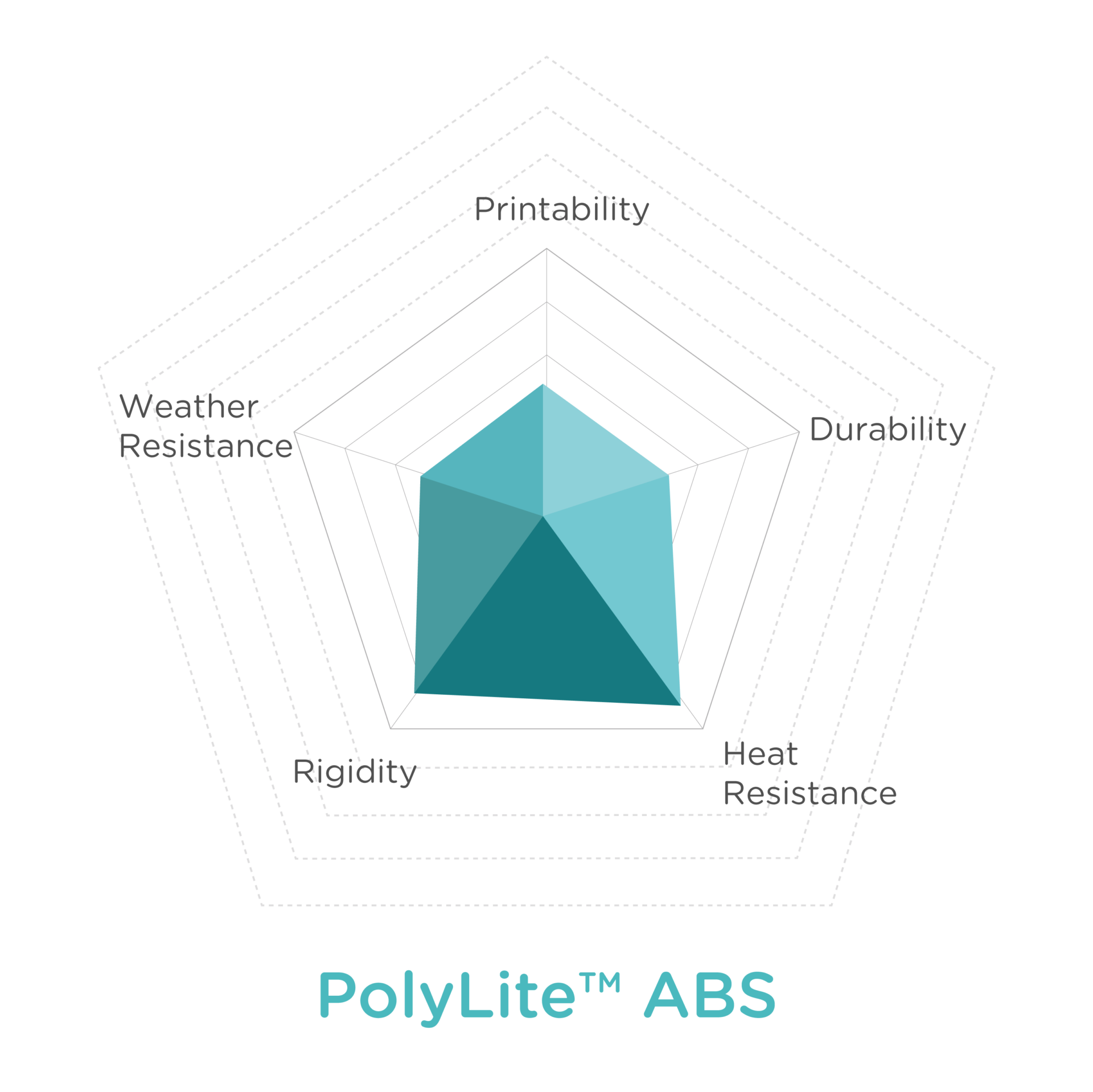

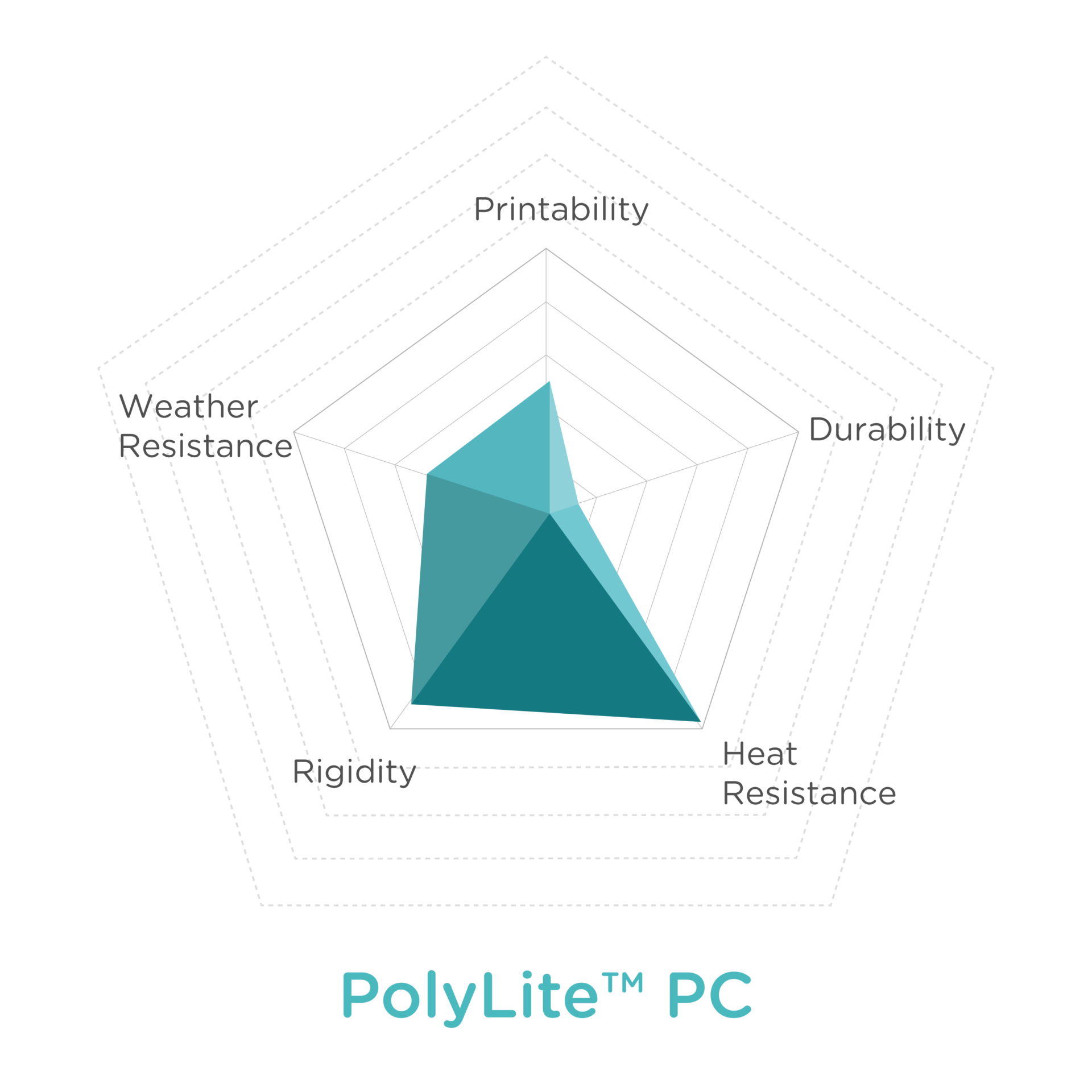

Picture 6 | Main Characteristics and Material Properties of PolyMax™ PC

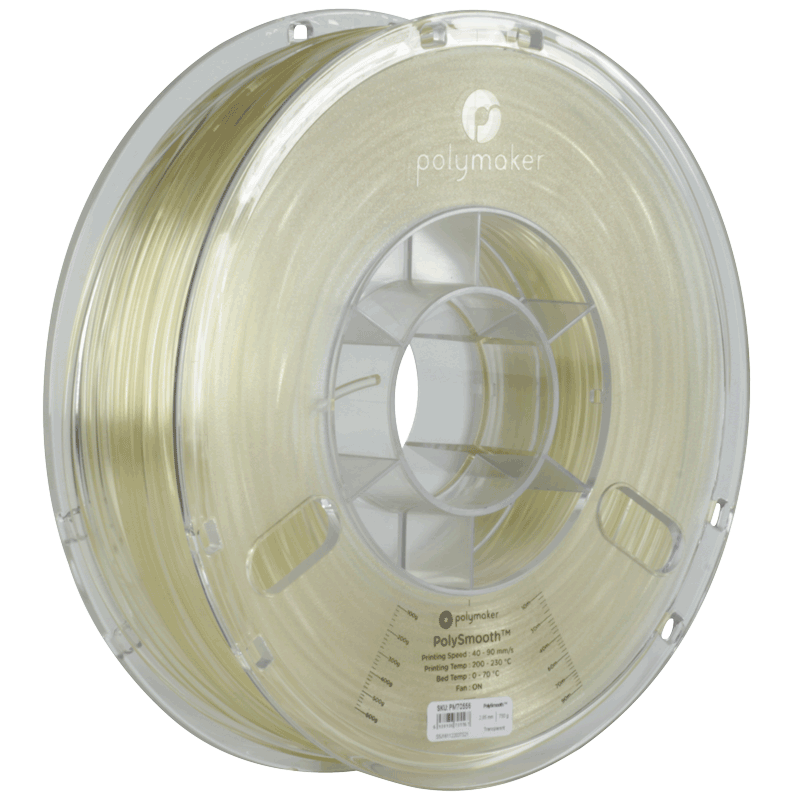

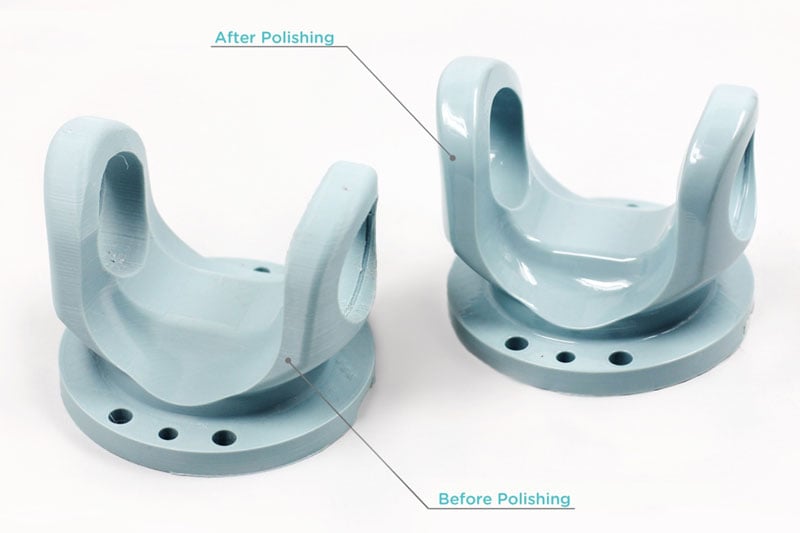

Polymaker’s Polysmooth™ has also been used to print the front flap variable section, wing, and suspension lug cover for the TR21. Using alcohol-polishing in the materials’ post-processing allows the external flow of the whole vehicle to be optimized.

Picture 7 | 3D-printed Front Flap Using Polymaker’s PolySmooth™

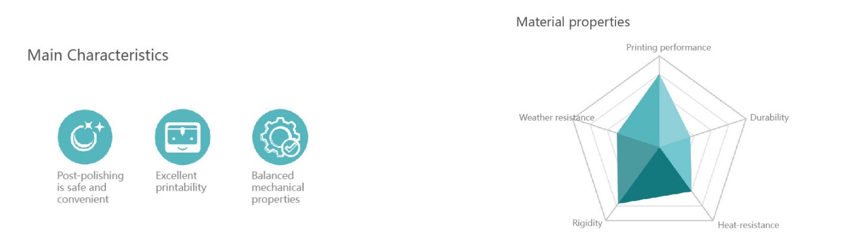

PolySmooth™ is a unique and easy-to-print filament, specially designed for "freeing both hands" in post-processing. After printing with this material, Polysher™ is then applied to create a smooth surface. PolySmooth™ helps models that are difficult to polish be post-processed into a smooth surface, like statuettes or role-playing props, making PolySmooth™ optimal for product design and prototype creation as it produces a result similar to injection molding.

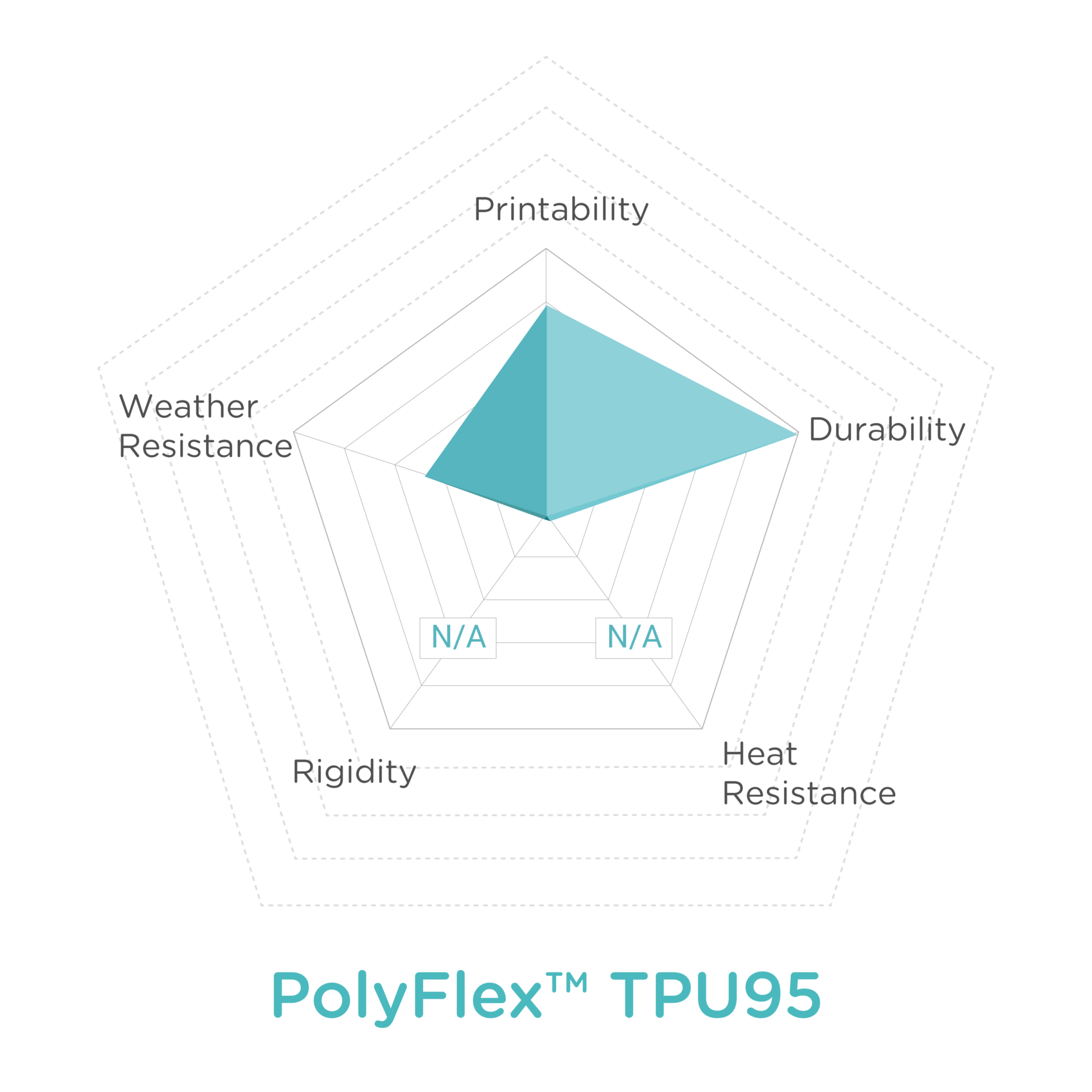

Picture 8 | Main Characteristics and Material Properties of PolySmooth ™

Brand New Chassis System

After a detailed analysis of tire characteristics, the original tires were replaced with Hoosier 16” high-performance racing slick tires. To match this tire, a new chassis system was designed for the TR21, equipped with a brake-by-wire stabilizing system to improve the vehicle’s dynamic performance.

Upgraded Electronic Control System

The TR21 continues to develop its electronic control system, using professional MoTeC ECU to have accurate control of the electronic throttle, pneumatic shift, and variable intake manifold while supporting wireless data acquisition. Also, the new steering wheel controller integrates radio communication, clutch-by-wire, brake-by-wire stability, ejection start control, traction control, and adjustment functions for various strategies, allowing drivers to enjoy its unlimited potential.

Picture 9 | TR21 Public Announcement Picture Groups

At this event, the TJU Racing Team announced their driverless vehicle plan for the first time, and they hope to see driverless technologies used in the next generation of TJU racing cars when they compete in the University Formula Race.

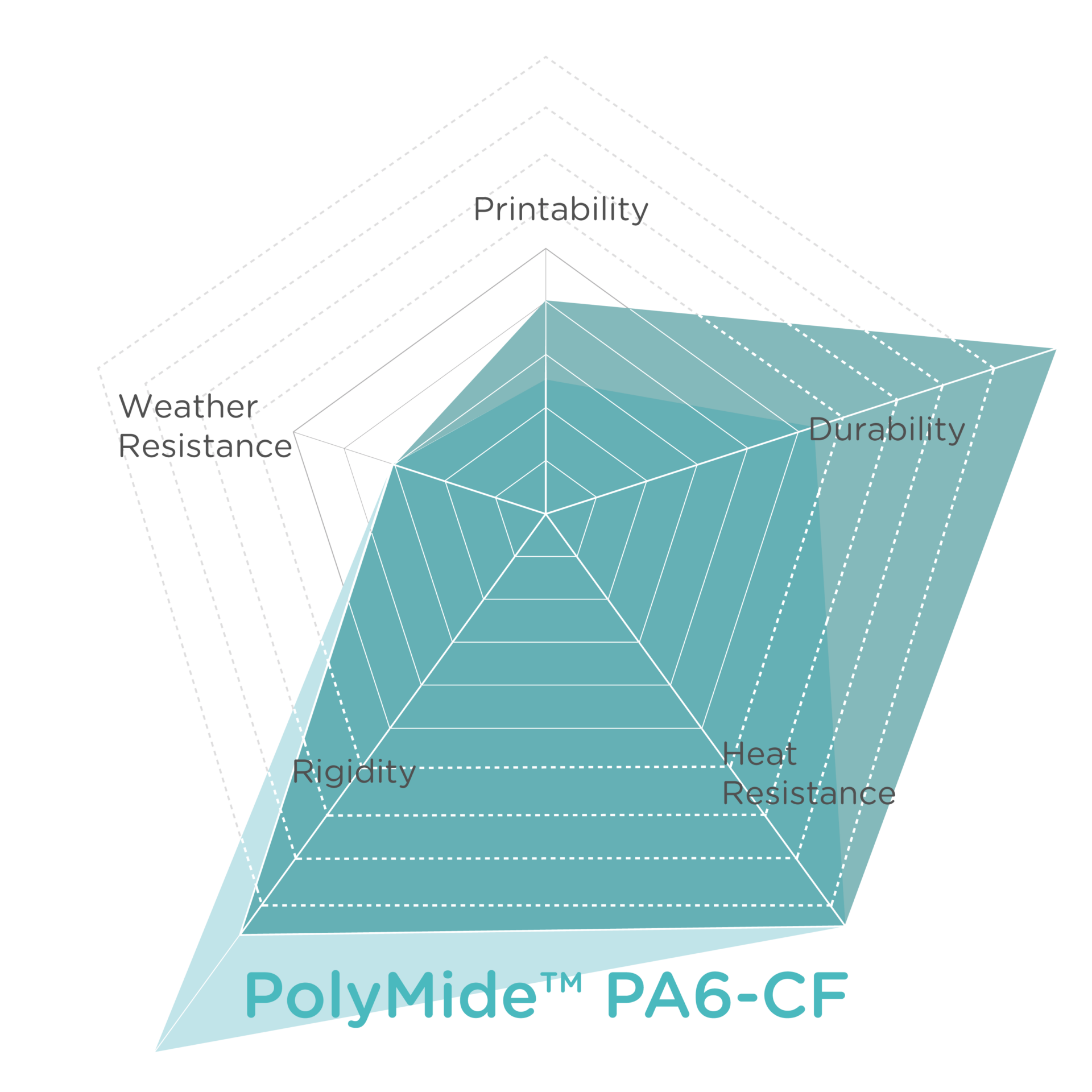

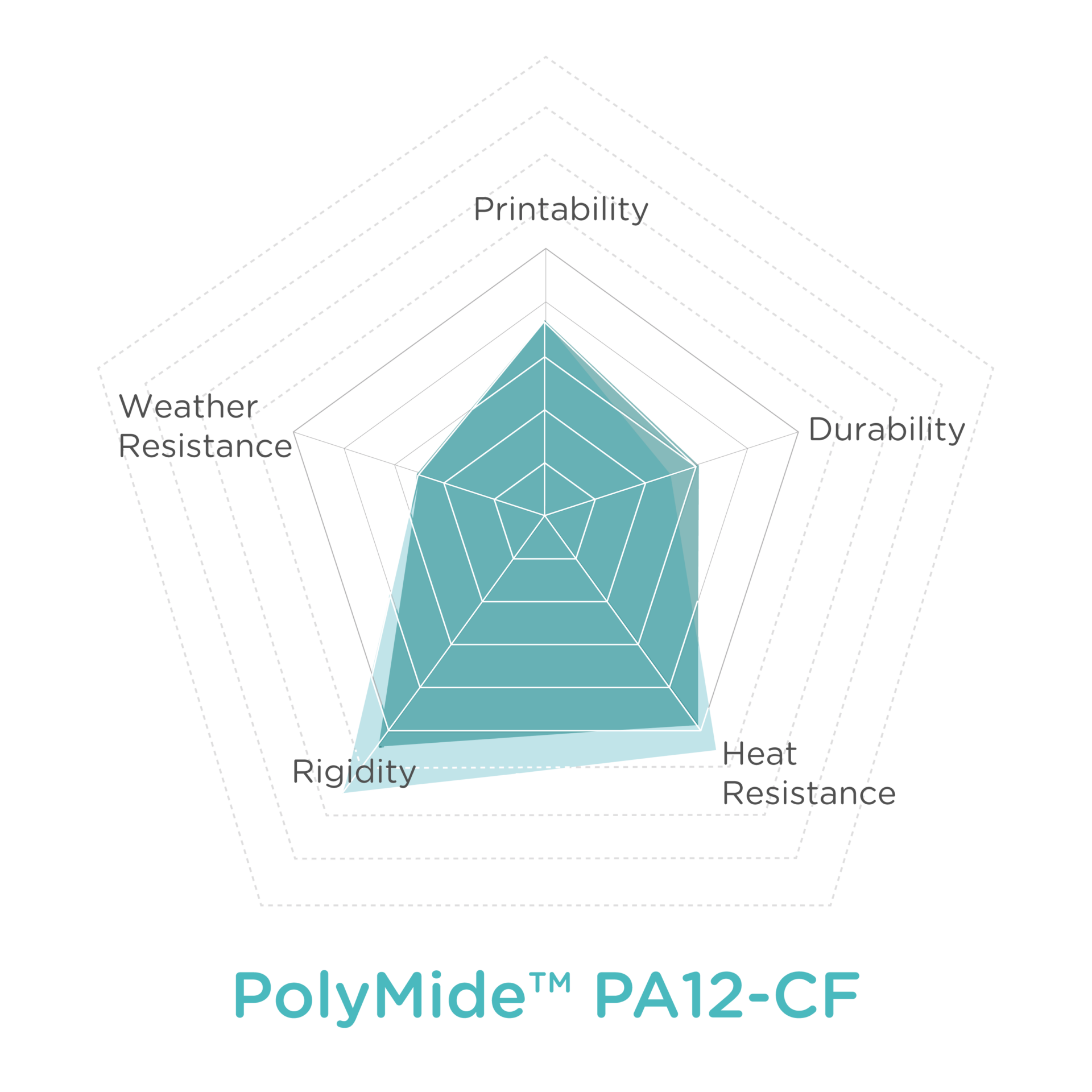

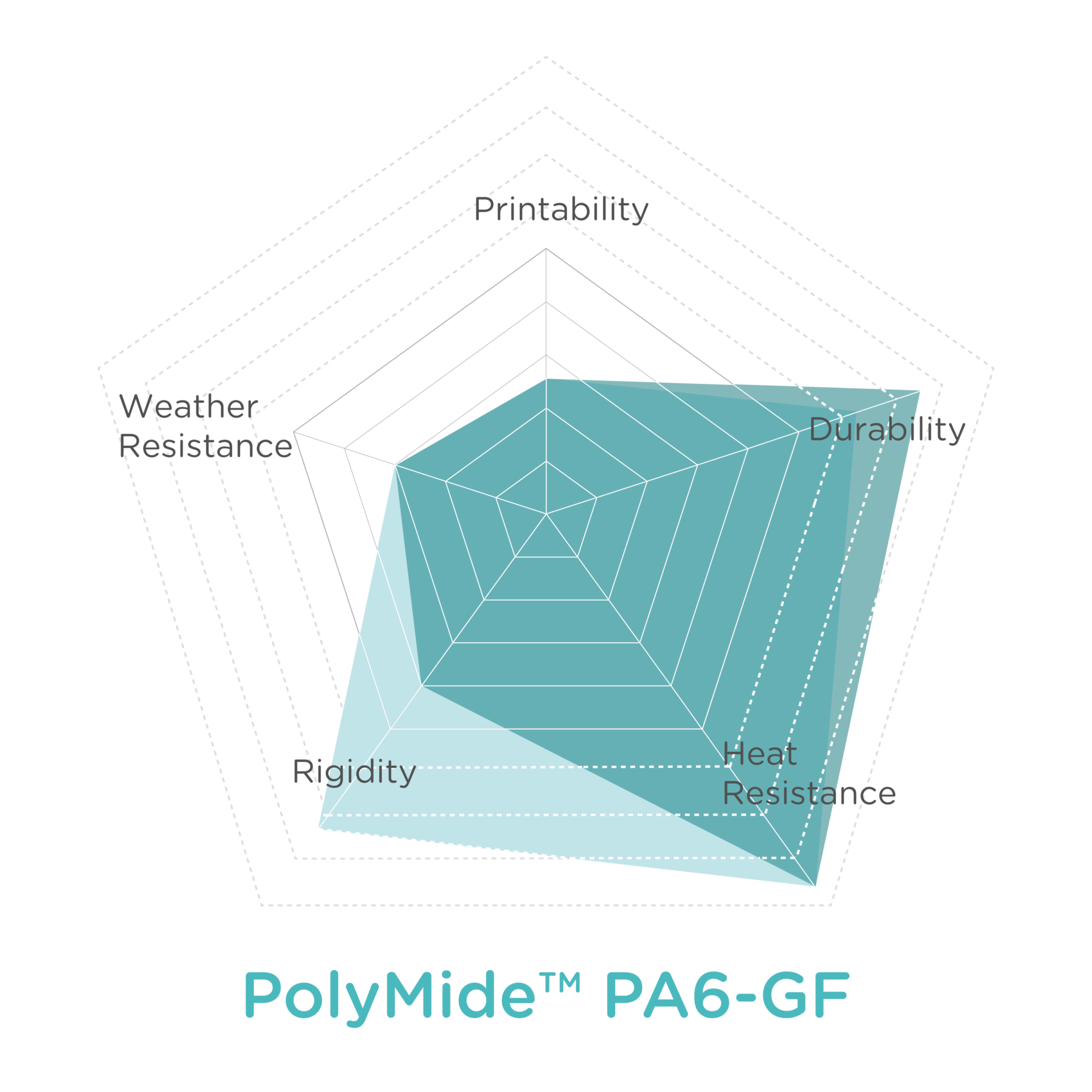

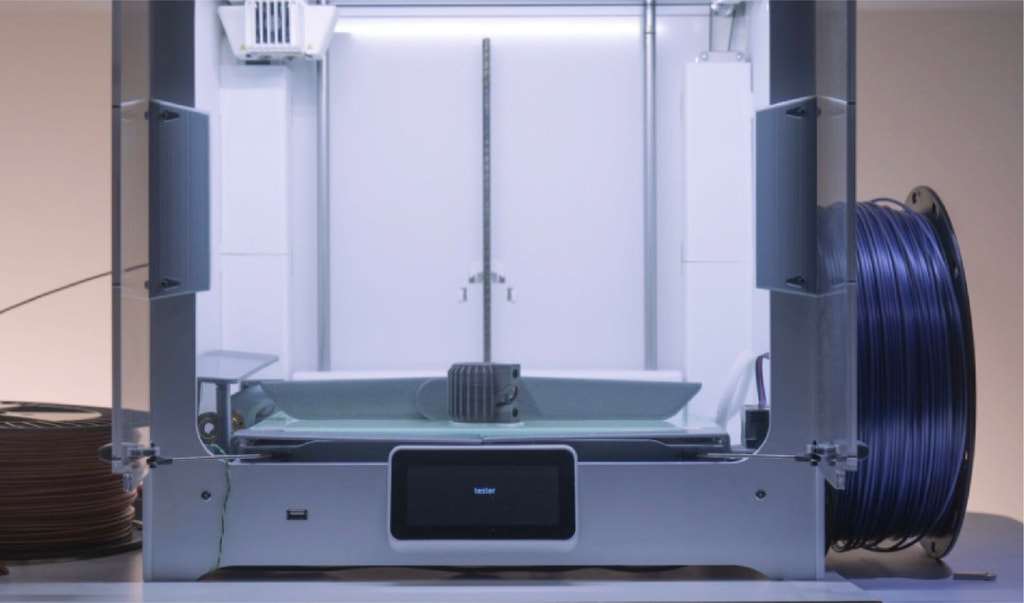

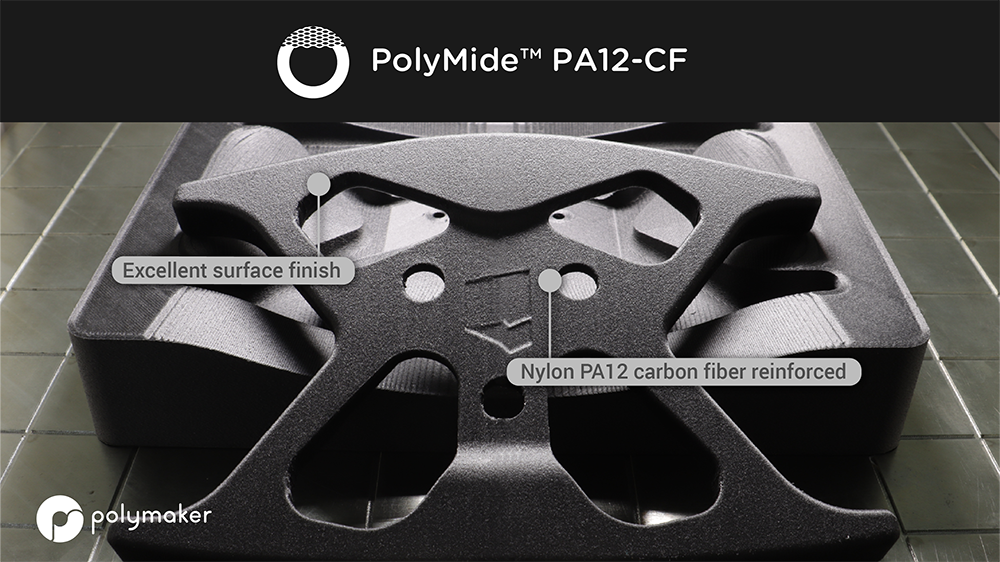

Polymaker has been actively involved in developing applications of 3D printing technology in the automotive and racing industry. Applying 3D printing materials allows for reduced costs, shortened production cycles, personalized customization, and lightweight parts to a certain extent. The diversity of Polymaker’s filaments also makes crafting different racing car parts more feasible, pushing the application of industrial-grade filament to be even more common. Polymaker's industrial-grade products include reinforced materials based on nylon mixed with carbon fibers and glass fibers, which improves their thermal properties and stiffness for interlayer bonding strength. There are also PC high fire-retardant materials and polymer alloy materials, both of which have high heat resistance and toughness.

We hope that 3D printing technology will be used widely when manufacturing and producing cars and racing cars in the near future.