Polymaker rises to the top to take home the Creative Application Award at this year's TCT360 exhibition in Birmingham, UK. The LEGO Go-Kart created by Matt Denton in partnership with Polymaker impressed this year's judges and was a crowd favourite at the award ceremony, gaining lots of cheers even before the winner was announced. The Creative Application Finalist selection was filled with some fierce competition such as: Stratasys, BMW, Shapeways, Ricoh 3D and Gravity Industries among many other impressive projects.

Polymaker win 2022 Creative Application Award

Polymaker win 2022 Creative Application Award

The first fully-electric ridable giant LEGO Go-Kart from Matt Denton. Scaled up 3D printed LEGO blocks printed on desktop FFF printers assembled into a fully working electric Go- Kart.

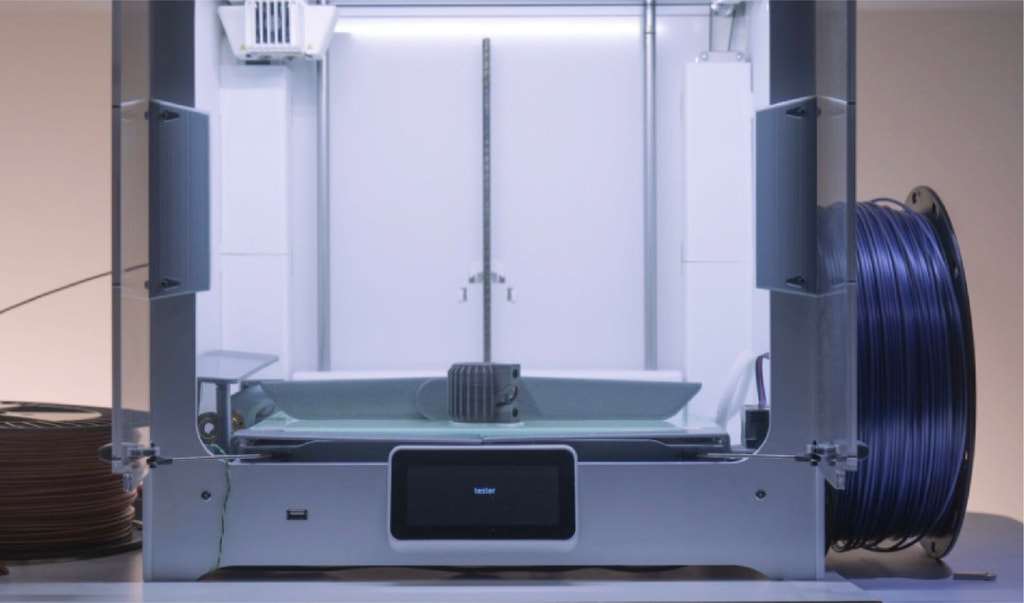

While the aesthetics of the Go-Kart are inspired by the LEGO Technics kits #1972 released in 1985. It was the electrification that created a challenge that required an original solution to a design that was not intended for human transportation. The use of desktop 3D printing enabled Matt to print all the bricks needed to assemble the Go-Kart with only a few non-3D printed parts, such as motors, brakes, and electronics. The end result is something that looks like it shouldn't drive, but when it does it's guaranteed to put a smile on your face.

Matt Denton and the LEGO Go-Kart

Matt Denton and the LEGO Go-Kart

The realisation that a fully functional Go-Kart can be 3D printed on your desktop and assembled with parts you can buy online will inspire people to think inside the blocks. Creativity can be applied to old concepts the same as new.

Absolutely everyone loves it, Matt has brought a childhood toy to life like something out of a pixar movie. Even the folks at LEGO spoke to Matt saying they love what he's doing. Matt displayed the Go-Kart on the Polymaker booth at FormNext 2021, the crowd response has been overwhelmingly positive with many people stopping to take pictures and ask Matt questions. Matt's YouTube videos have gained over 1.8 million views related to the Go-Kart project.

Sjoerd & Gisela collect the Creative Application Award at the TCT award ceremony

Sjoerd & Gisela collect the Creative Application Award at the TCT award ceremony

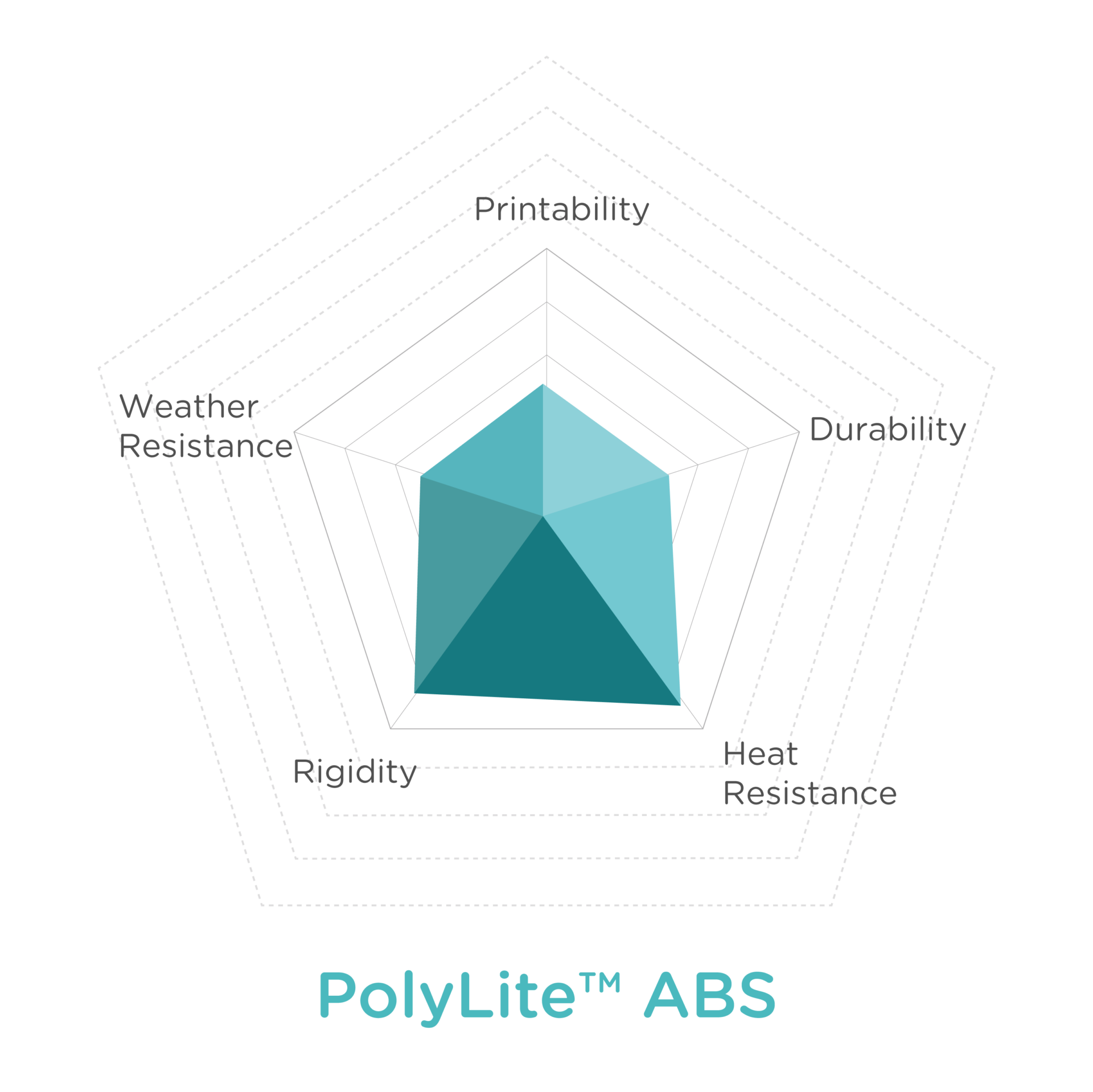

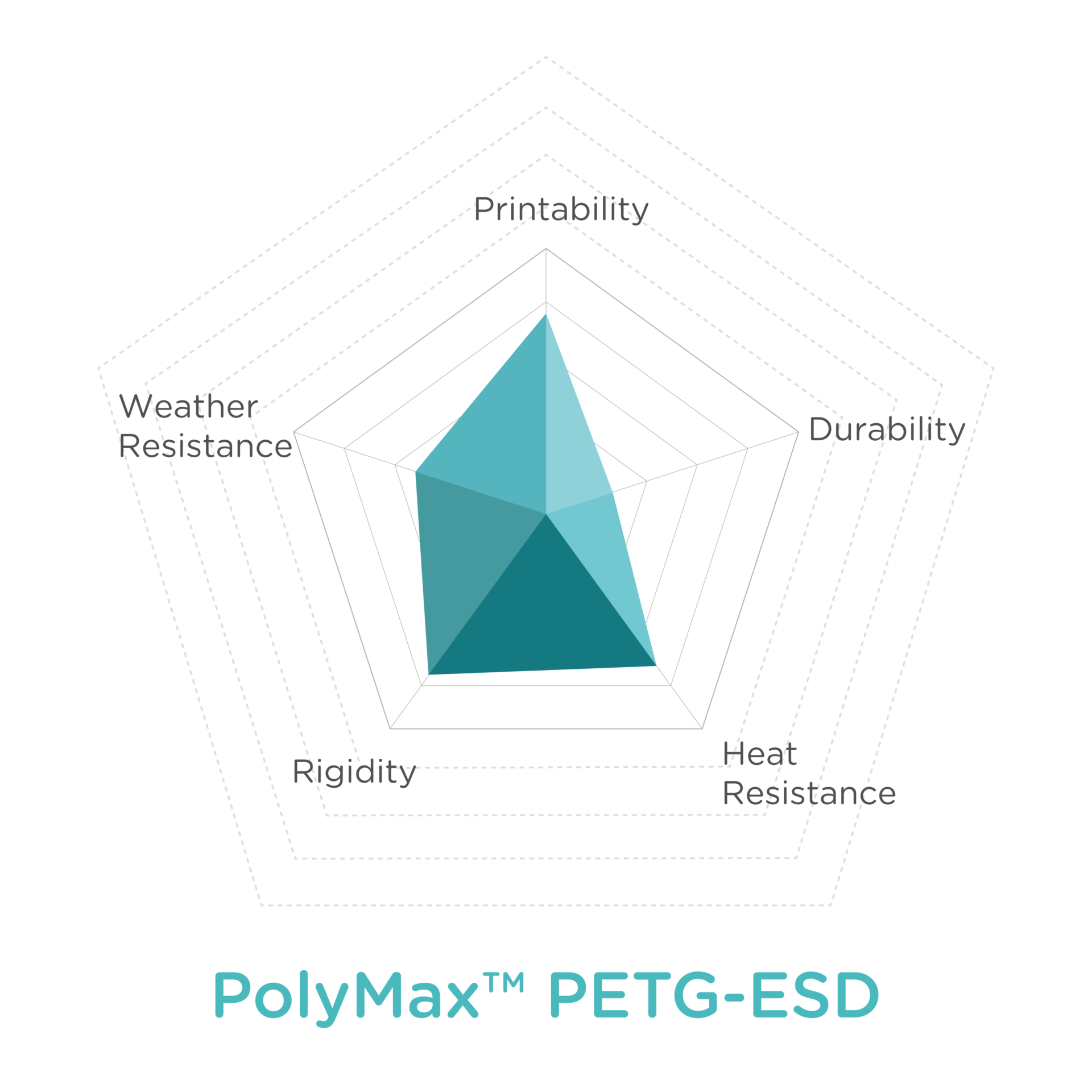

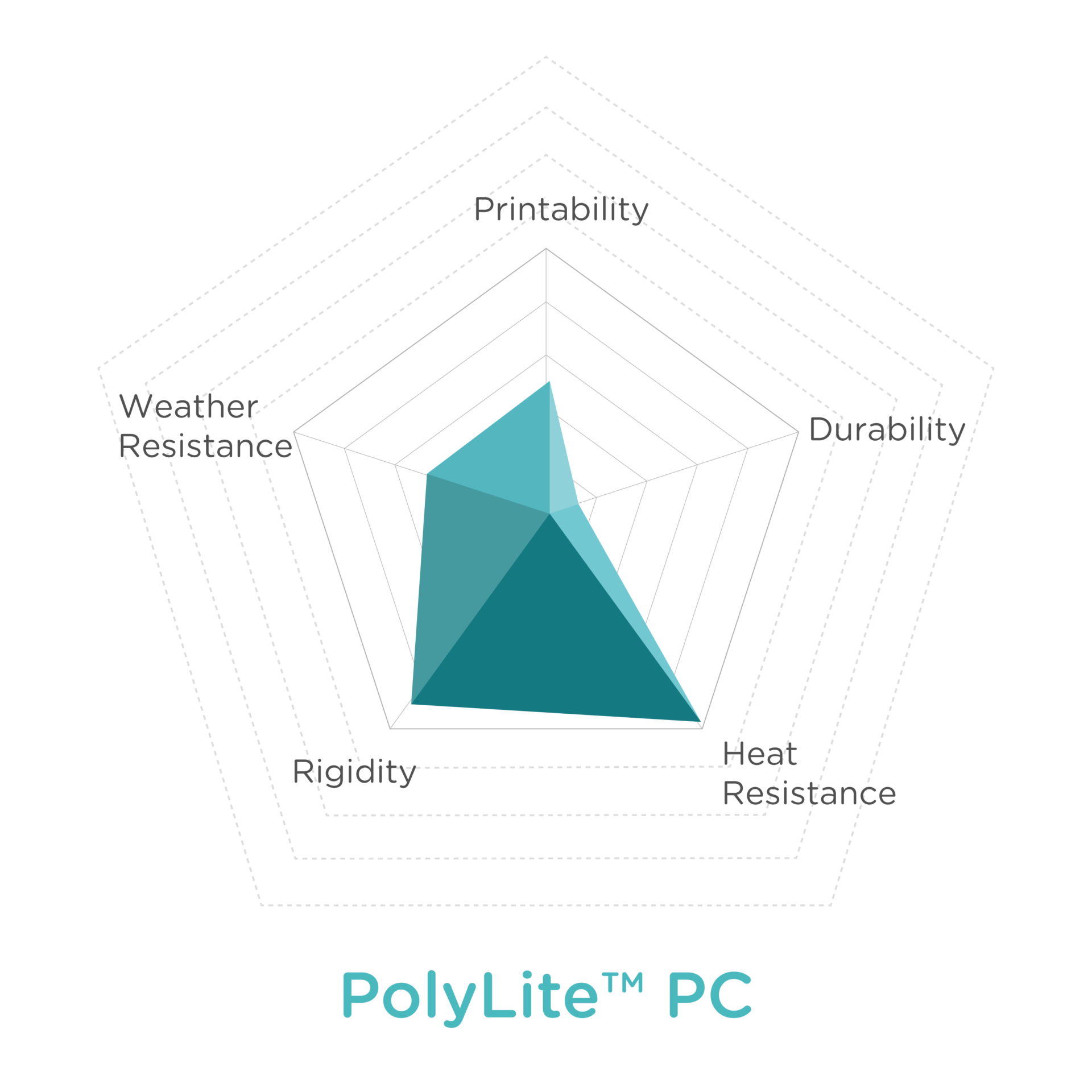

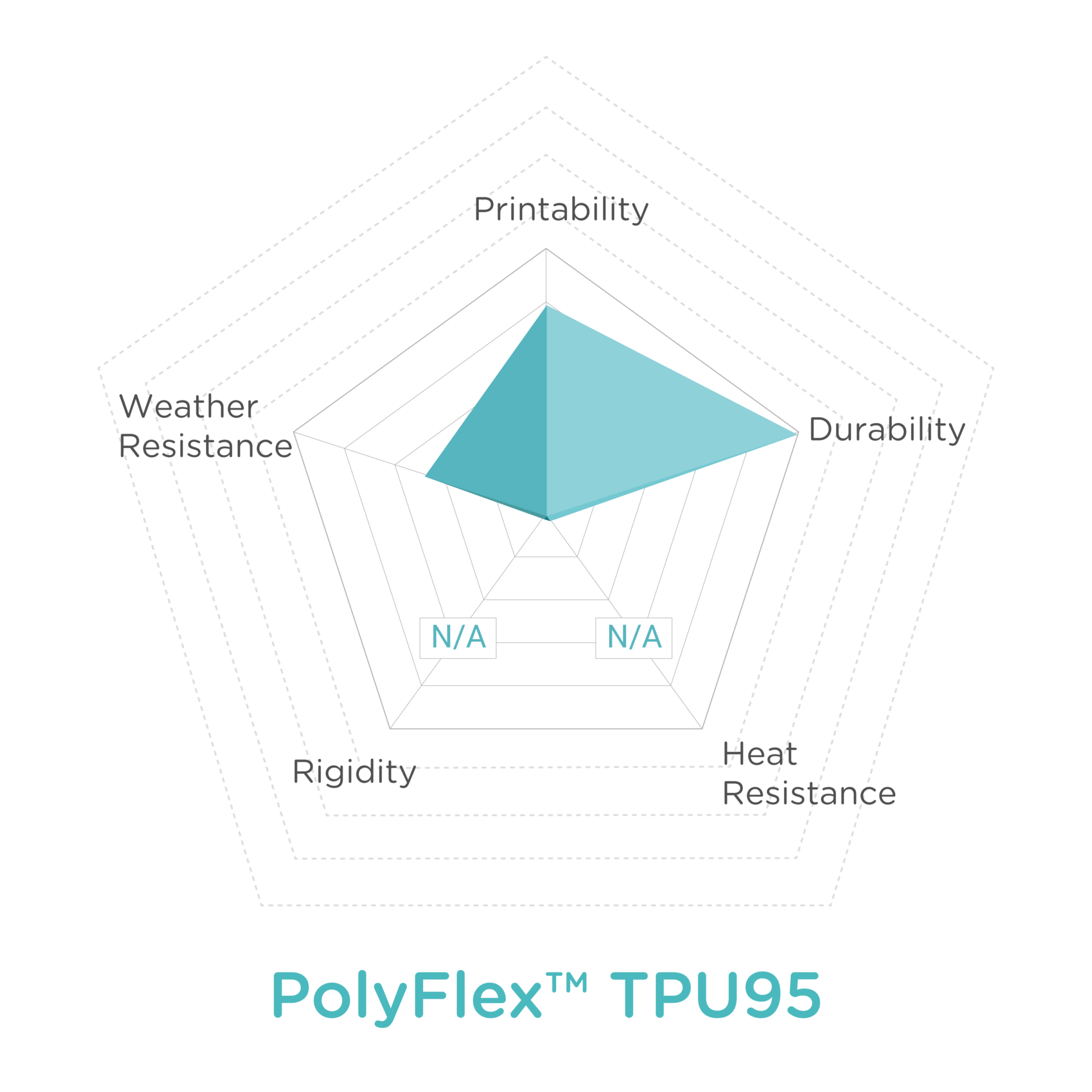

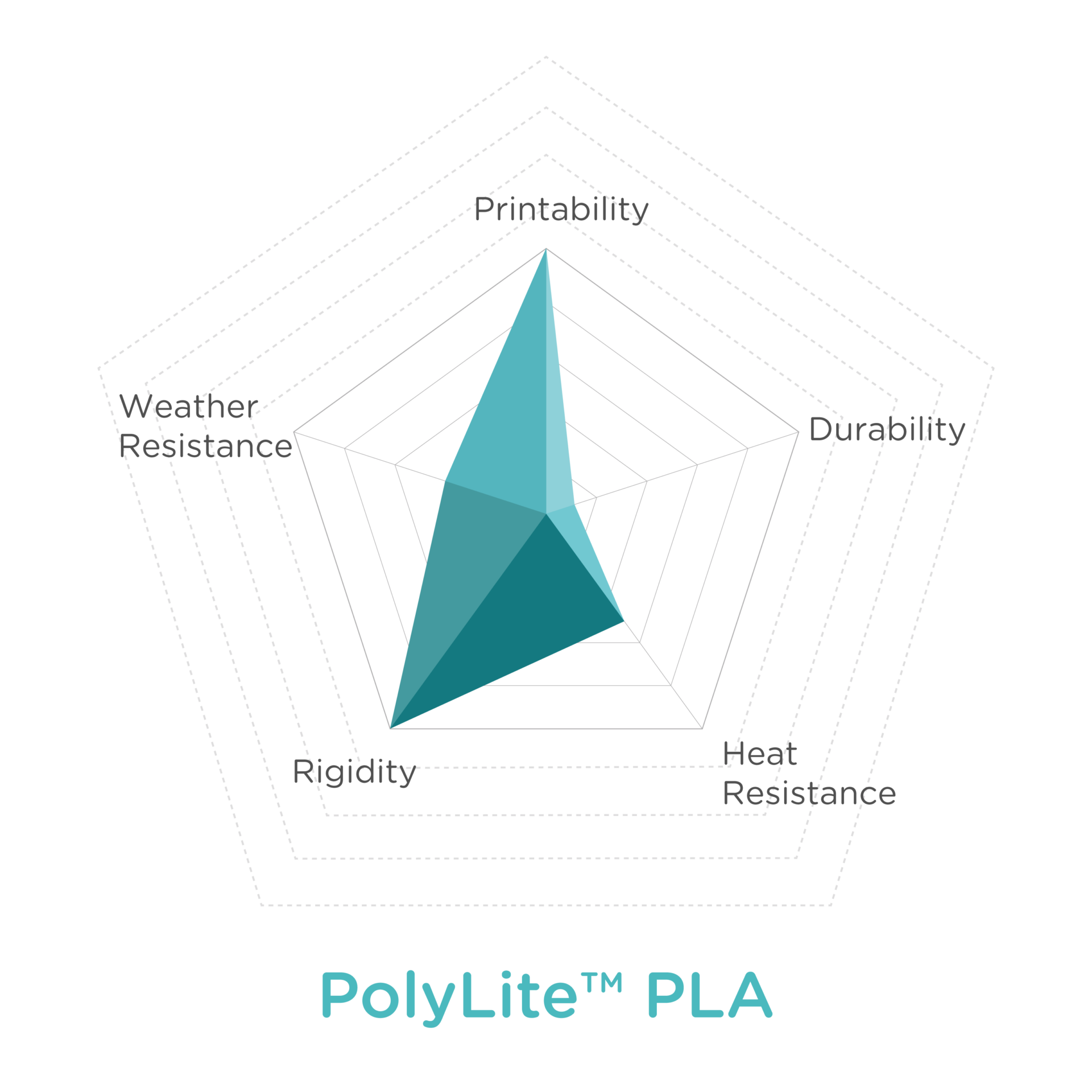

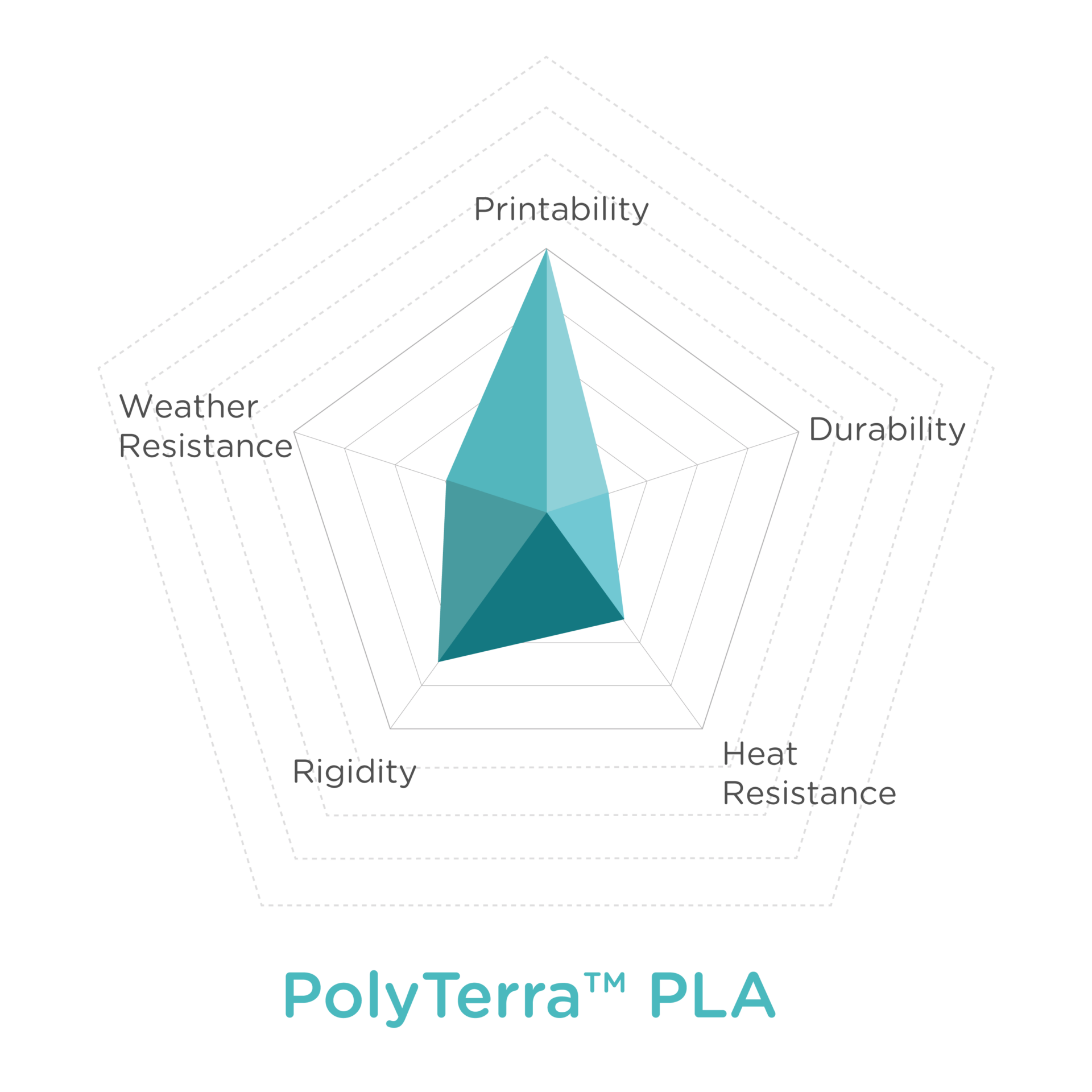

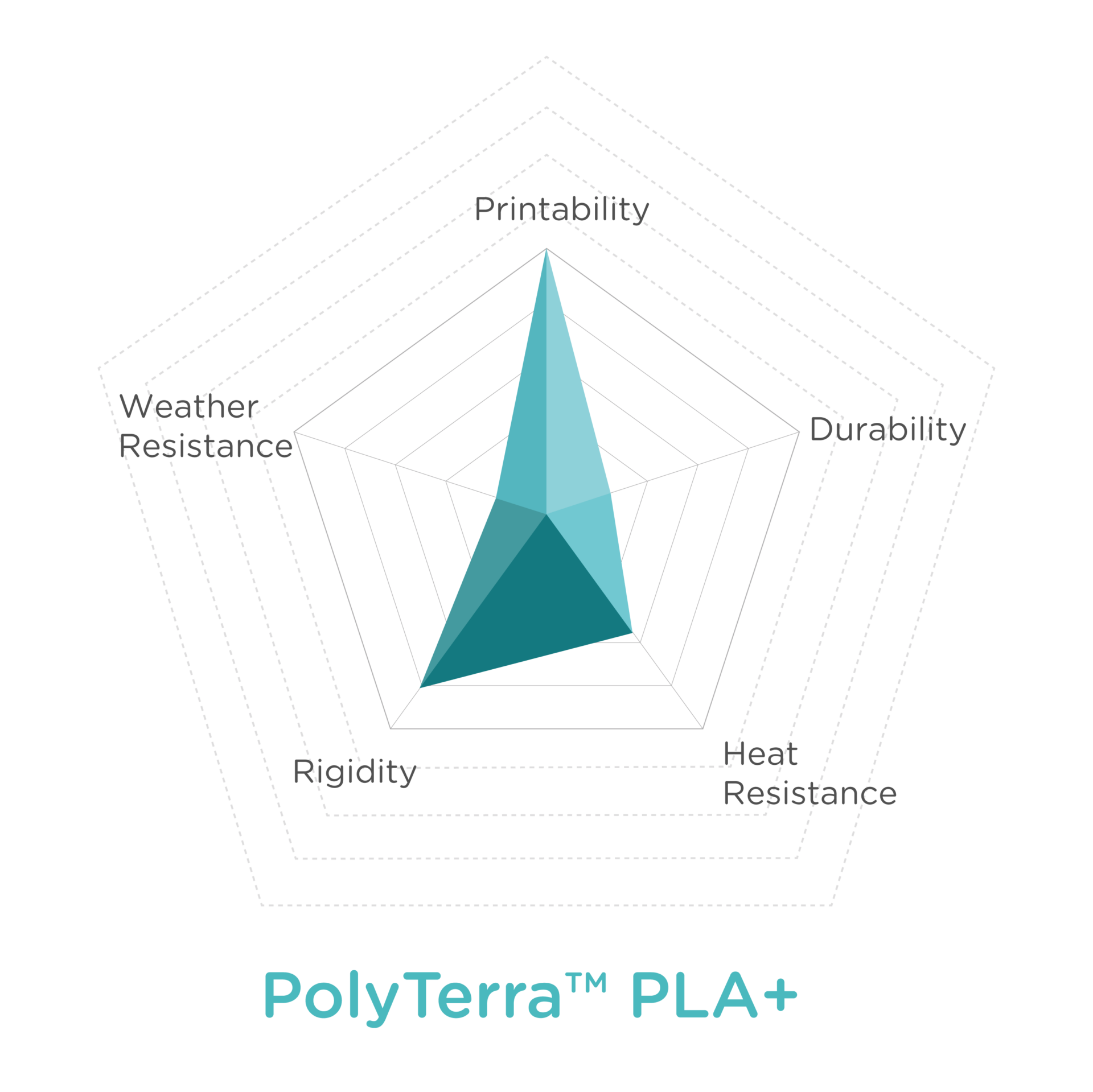

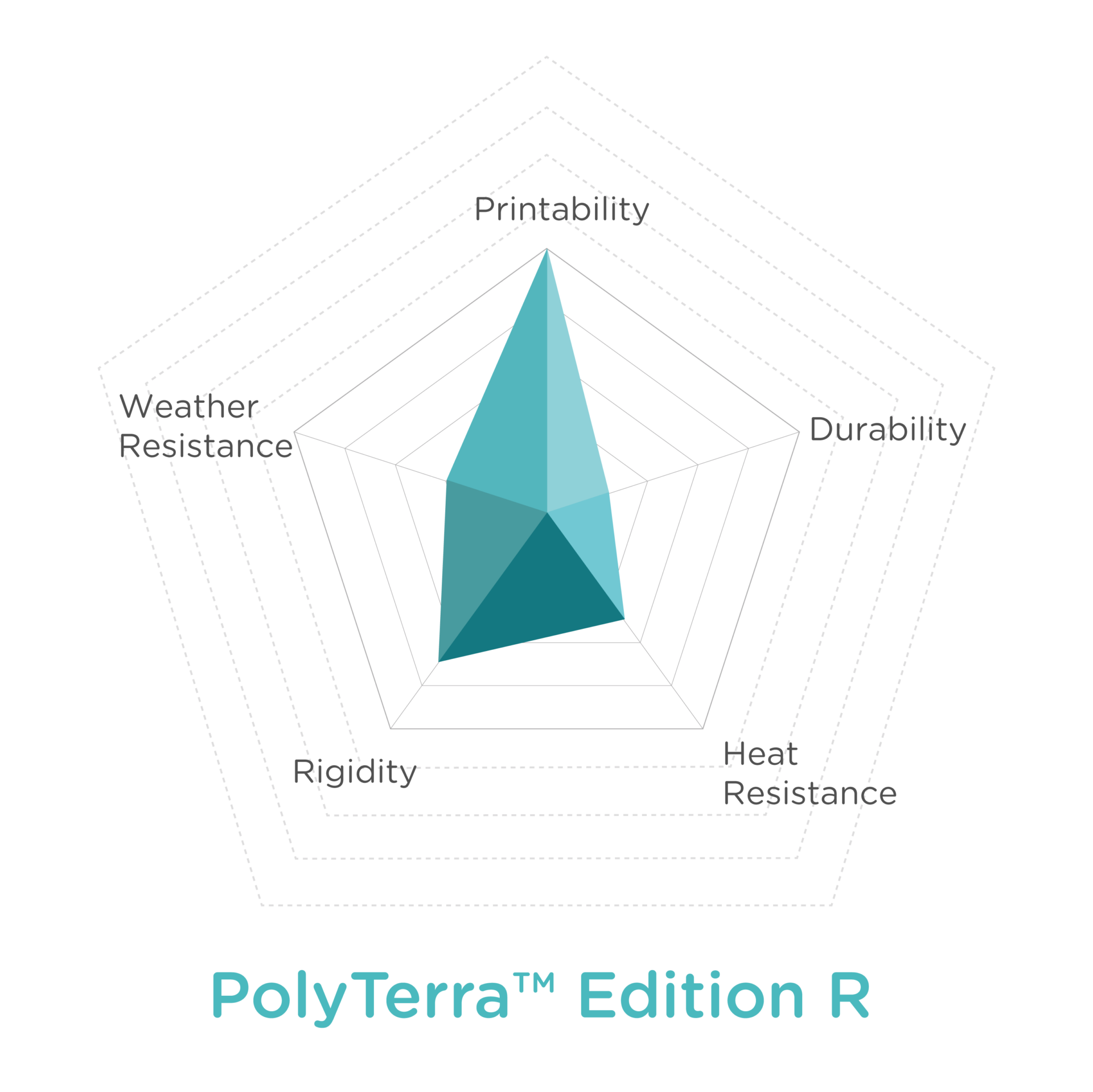

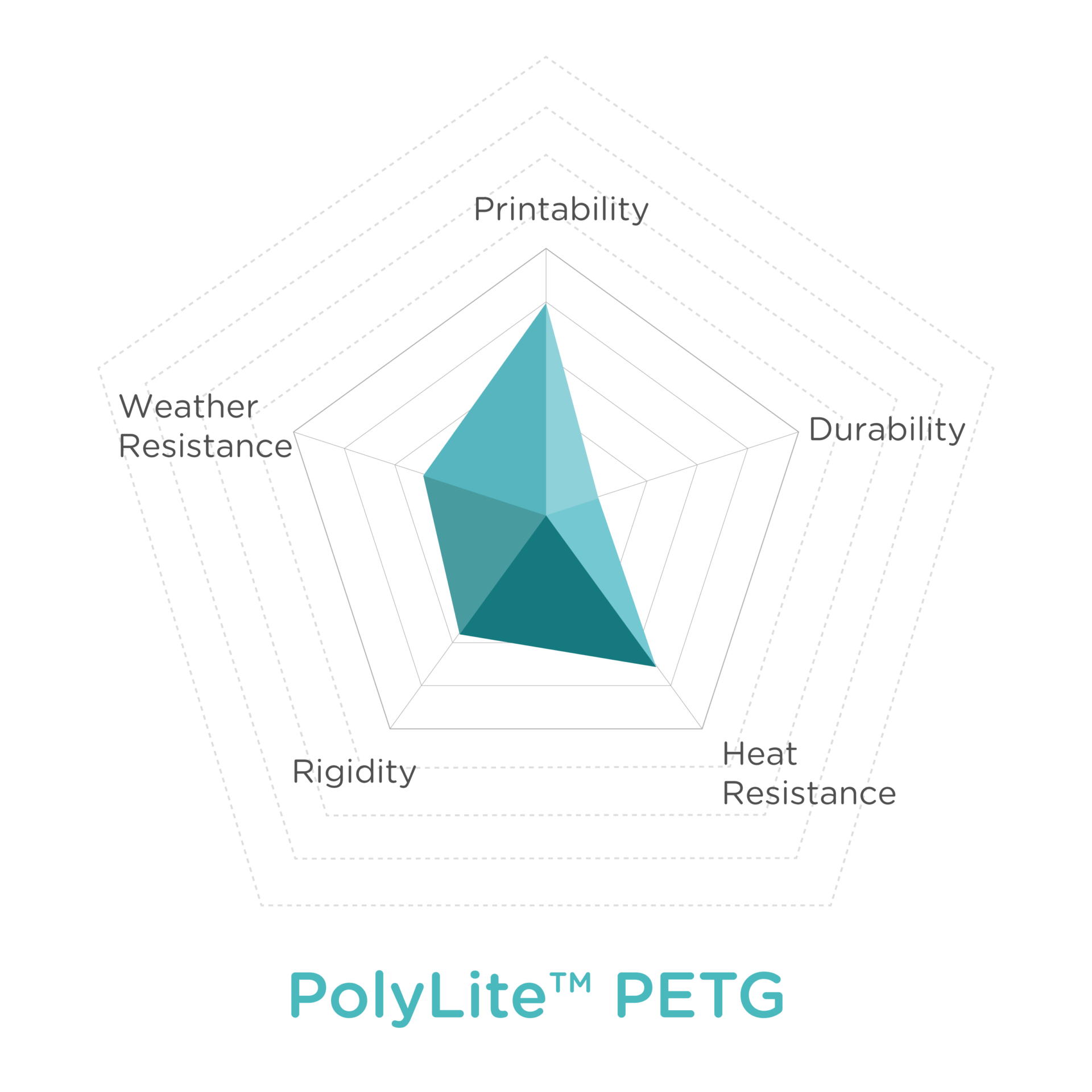

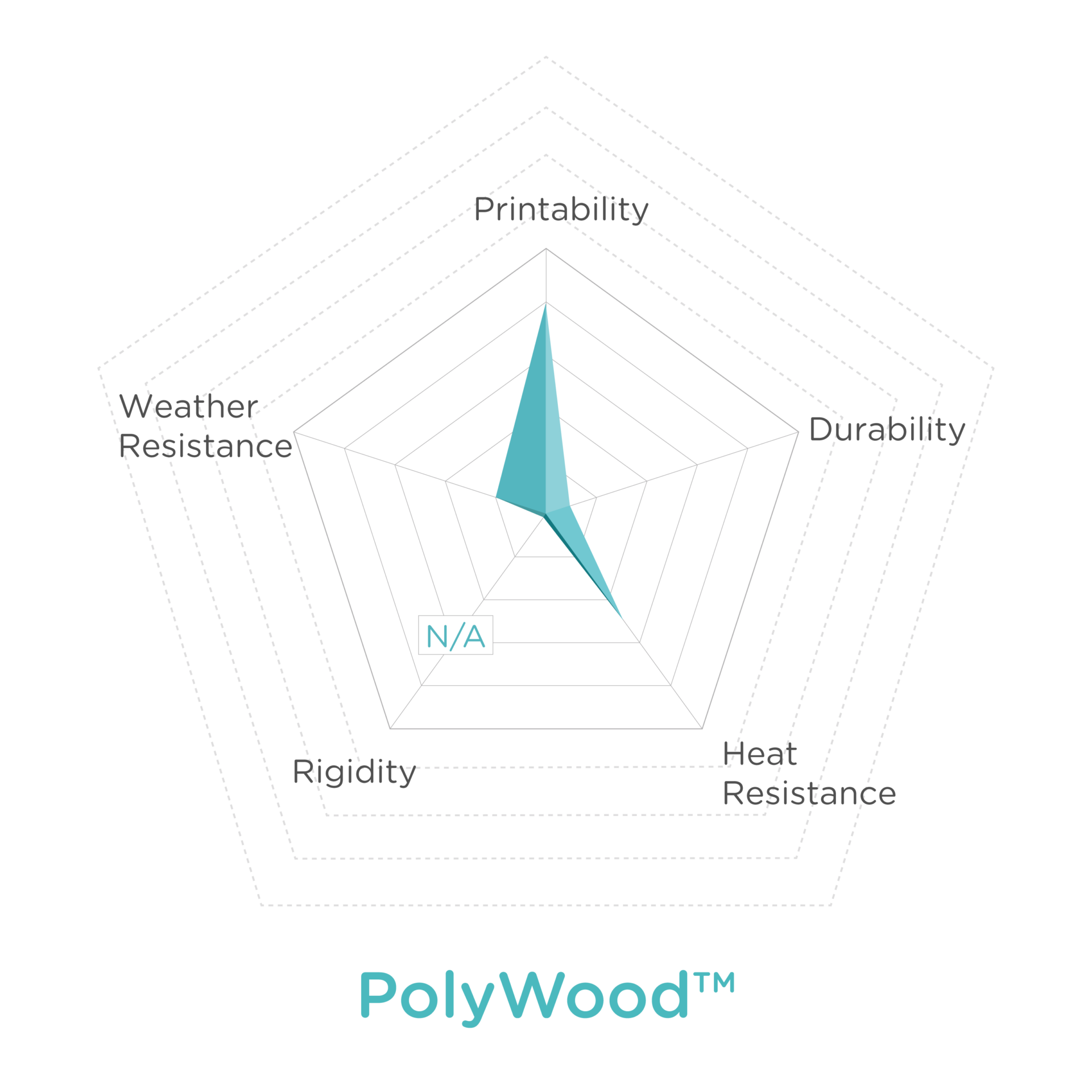

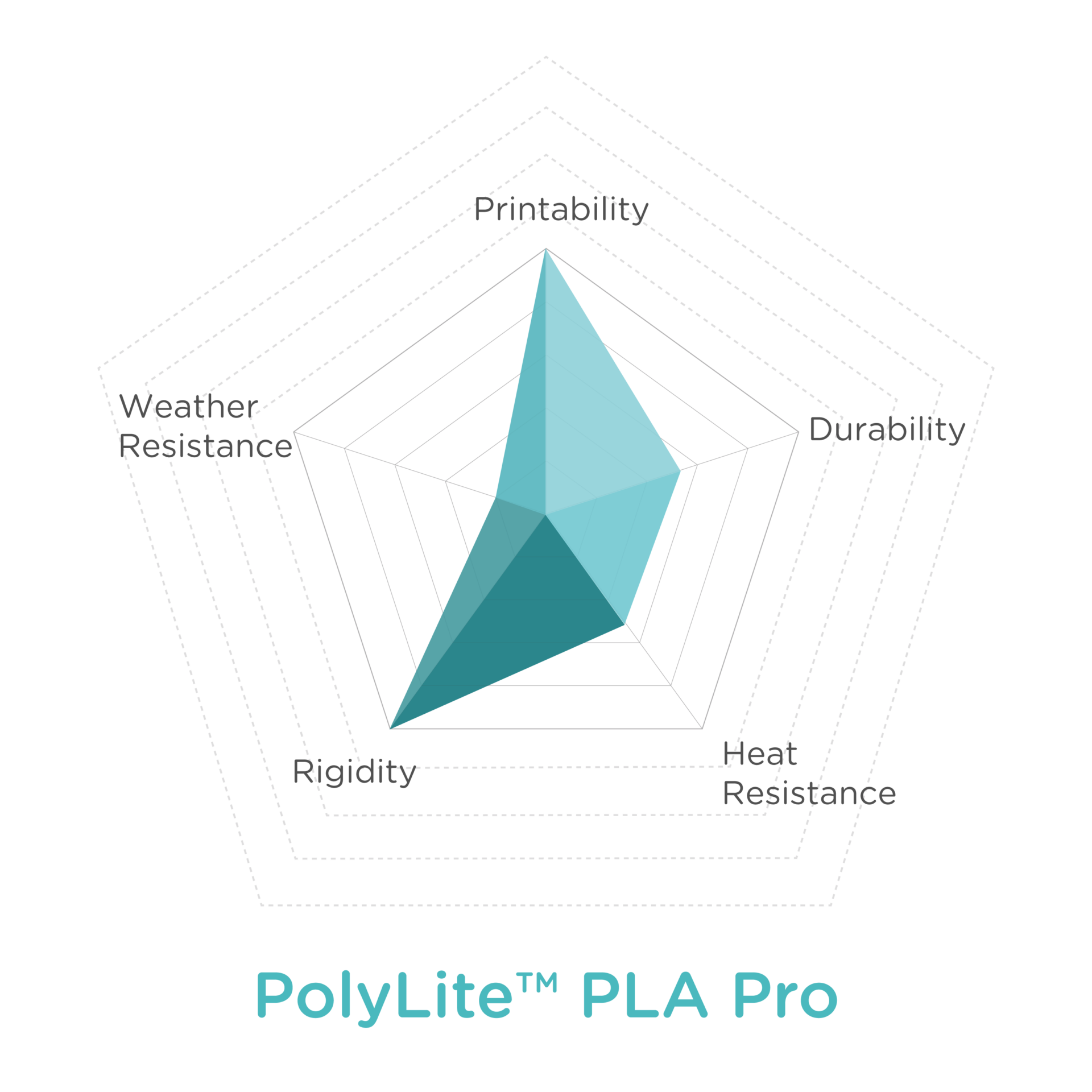

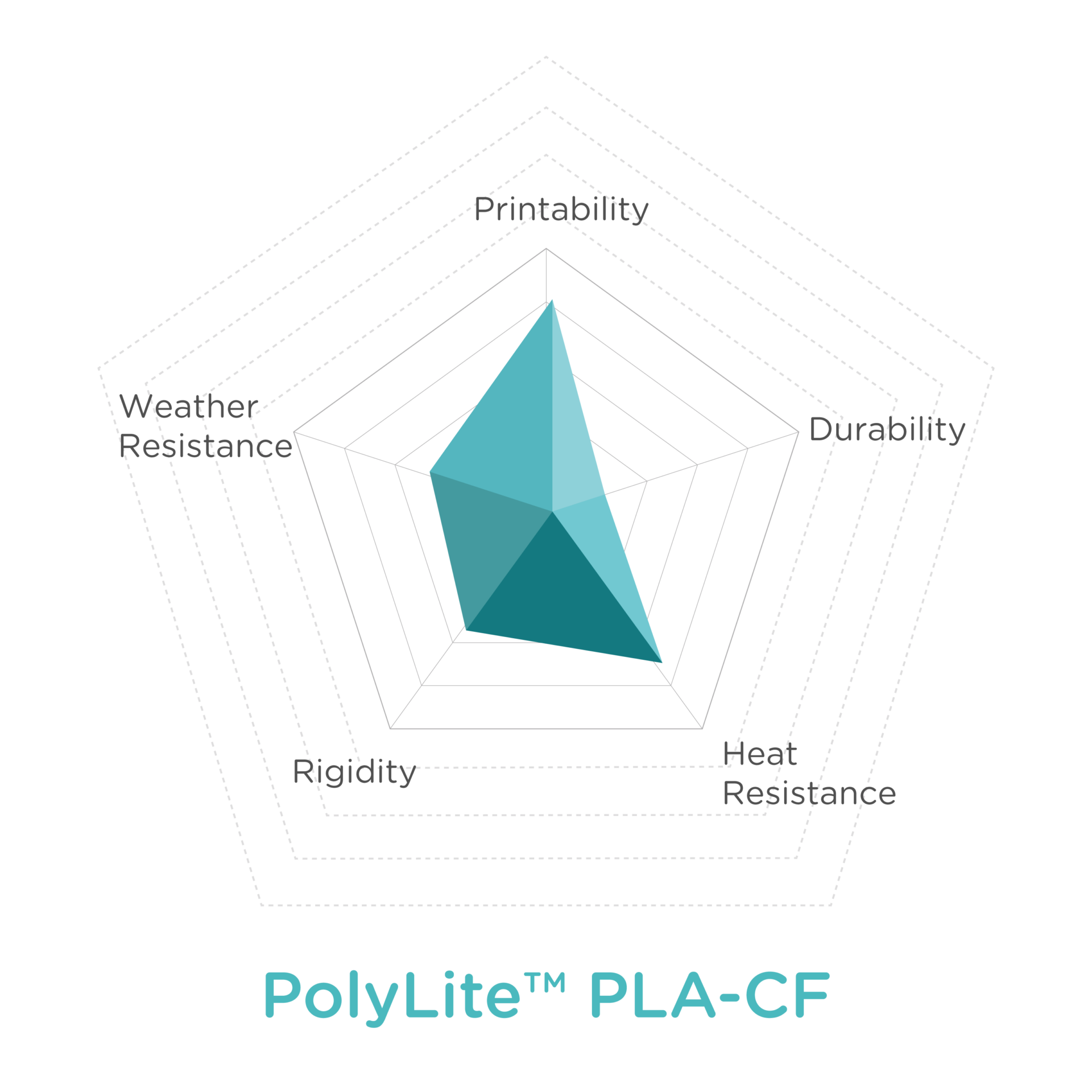

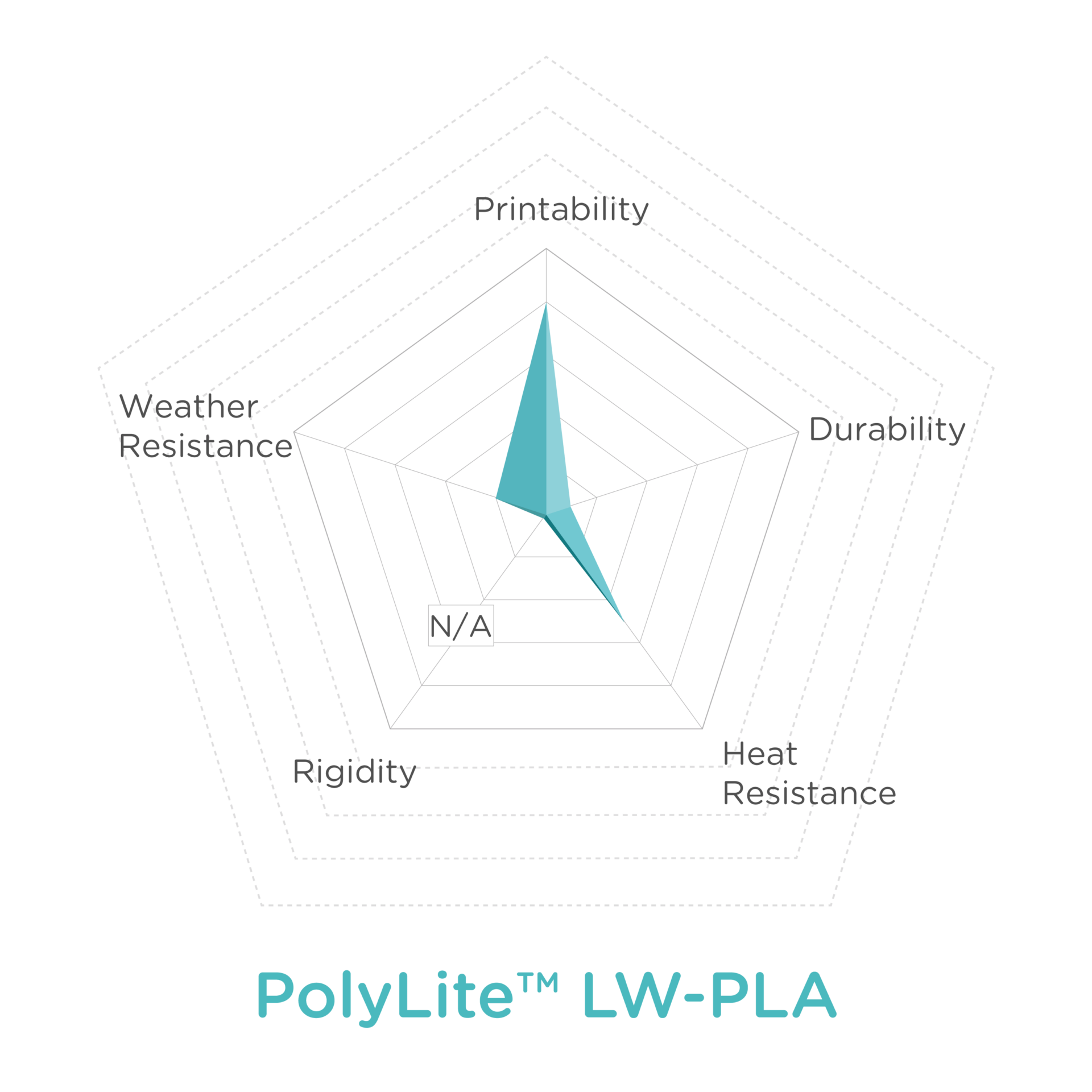

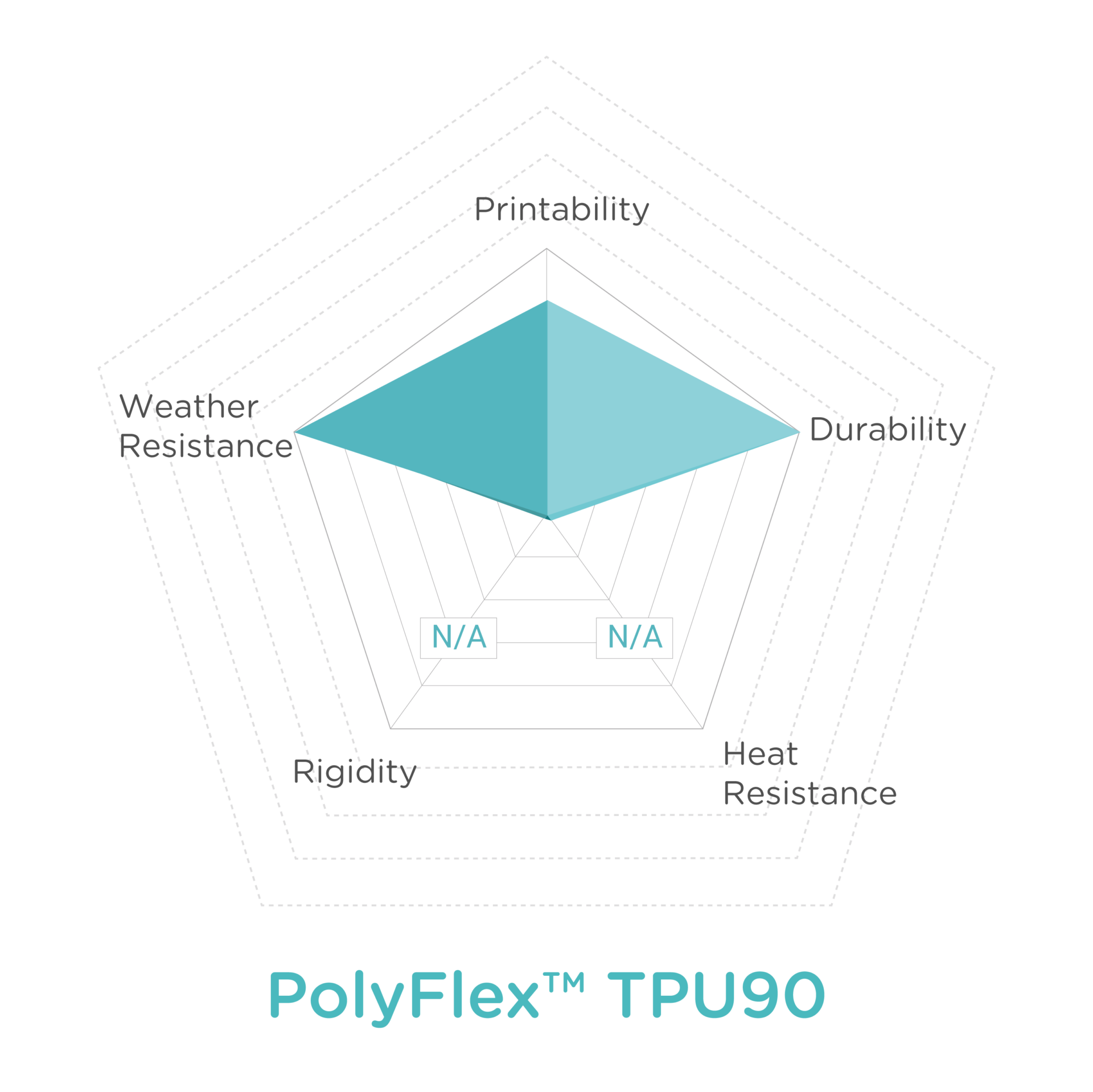

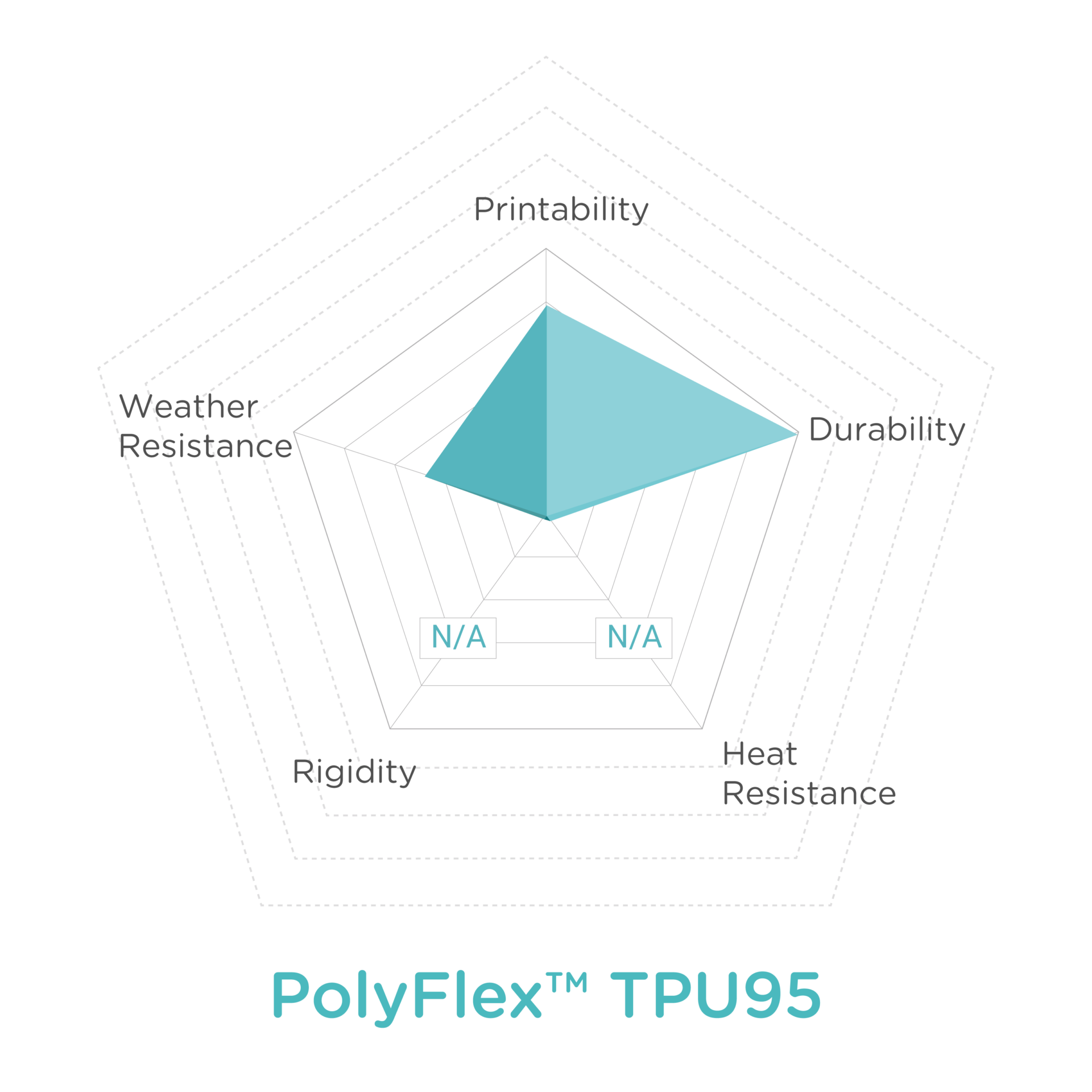

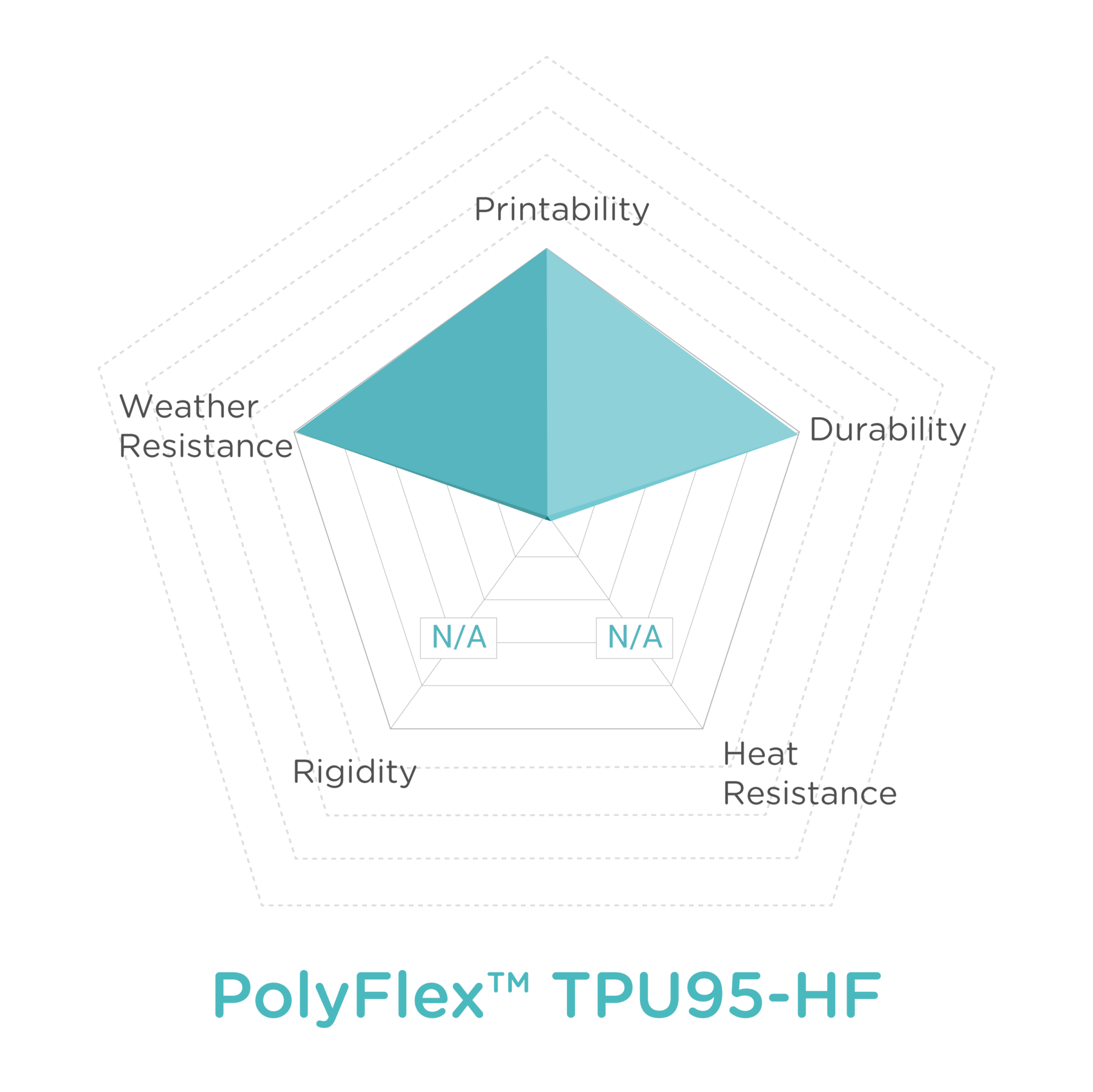

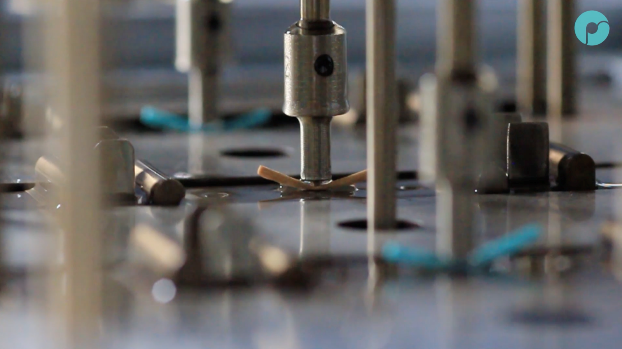

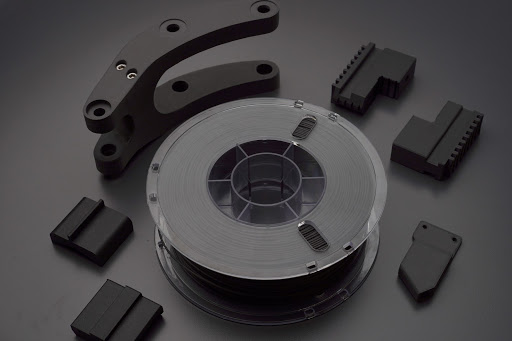

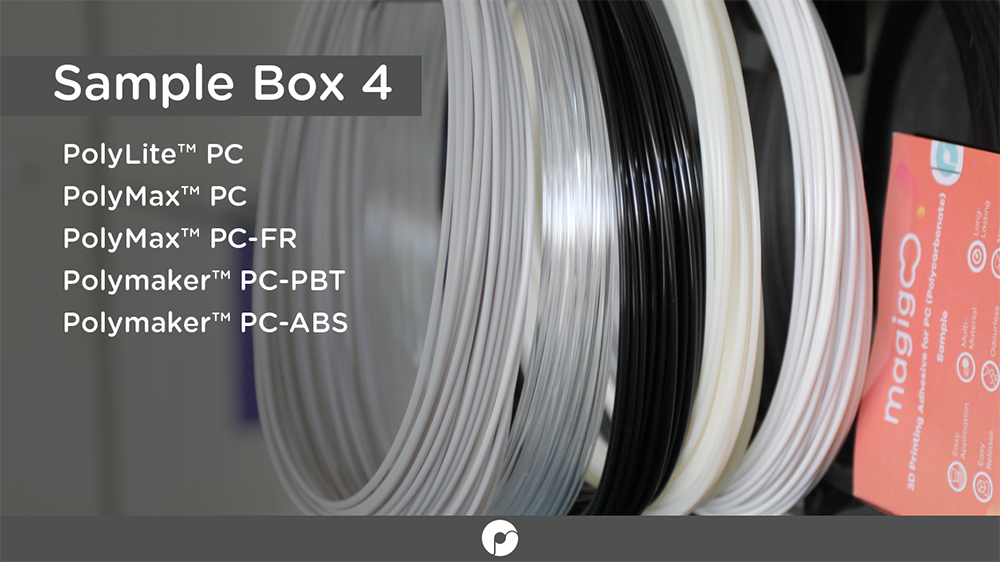

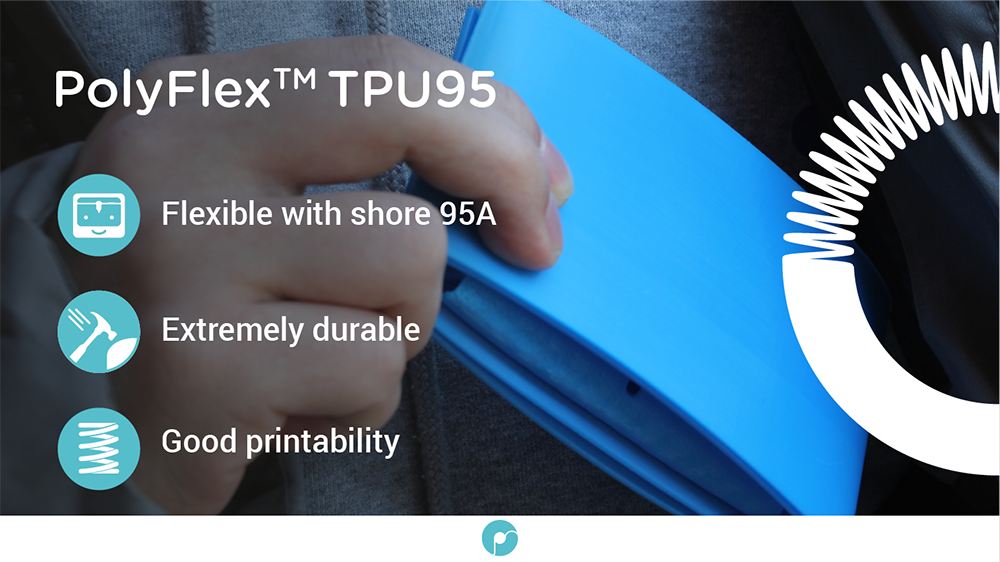

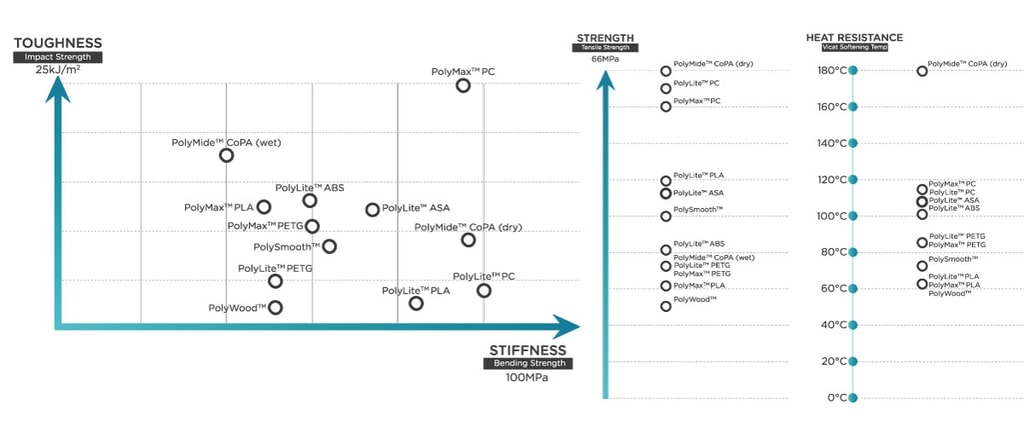

All materials for the Go-Kart were supplied by Polymaker. Matt choose a wide range of filaments as the material needs differed from brick to brick. The chassis bricks were printed in PolyMax™ Tough PLA, the gears in PolyMax™ Tough PETG, the axles in PolyMax™ Tough PC, the tyres in PolyFlex™ TPU95. Finally, PolyLite™ PLA was used for some cosmetics parts. The combination of materials allowed Matt to take advantage of the mechanical properties of a wide range of filaments which were all compatible with his desktop printing setup.

Matt with all the 3D printed LEGO bricks

Matt with all the 3D printed LEGO bricks3D printing is the only way to create this Go-Kart. Even if you paid the ludicrous amount of money for the tooling of these giant blocks, a solid injection moulded brick would be too heavy. 3D printing allowed Matt to have a number of slight variations to the bricks so that they could hide bearings or route cables without spoiling the aesthetic. With a desktop 3D printer over 95% of all the parts were printed at home by Matt on a 300mm x 300mm x 300mm print bed.

Electric vehicles are the way forward as we reduce our carbon emissions. Showing people that they can print their own vehicles at home reduces heavy emitting big industry and localizes manufacturing. This, in turn, eliminates the need to ship products around the globe further reducing emissions. 3D printing gives the ability to manufacture locally and this project is a great example of what can be achieved with inexpensive desktop 3D printers at home in your bedroom.

The classic design touches a special place in our younger hearts, reminding us of a simpler time when our creativity could run free. Everyone who played with LEGO when they were a child is instantly reminded of the familiarity of this project. A large scale model on its own would still invoke this feeling, but the fact that this isn't just a model, its a rideable electric vehicle which adds even more charm to the project.

Just as the original technics kit from 1985 inspired Matt to take up engineering. He now hopes that this new generation armed with 3D printers can realize their potential by following in Matt's footsteps. The ability to design and customize parts enabled Matt to create the Go-Kart without spoiling the LEGO aesthetic. Matt's videos break down the individual parts and he explains the design choices he made. With over 20 years working in the special effects industry for TV & Film, Matt's experience paired with a fun project provides an engaging educational and problem-solving demonstration.

Matt has already posted his next video which involves some PolyMax™ PC drifting sleeves. The 3D printed sleeves will fit over the rear tyres greatly reducing the grip that the PolyFlex™ TPU95 provides, instead, the rear wheels can spin with less friction allowing Matt to drift the Go-Kart around.

Matt will reprint the PolyMax™ PETG gears to give a higher speed ratio necessary for drifting.

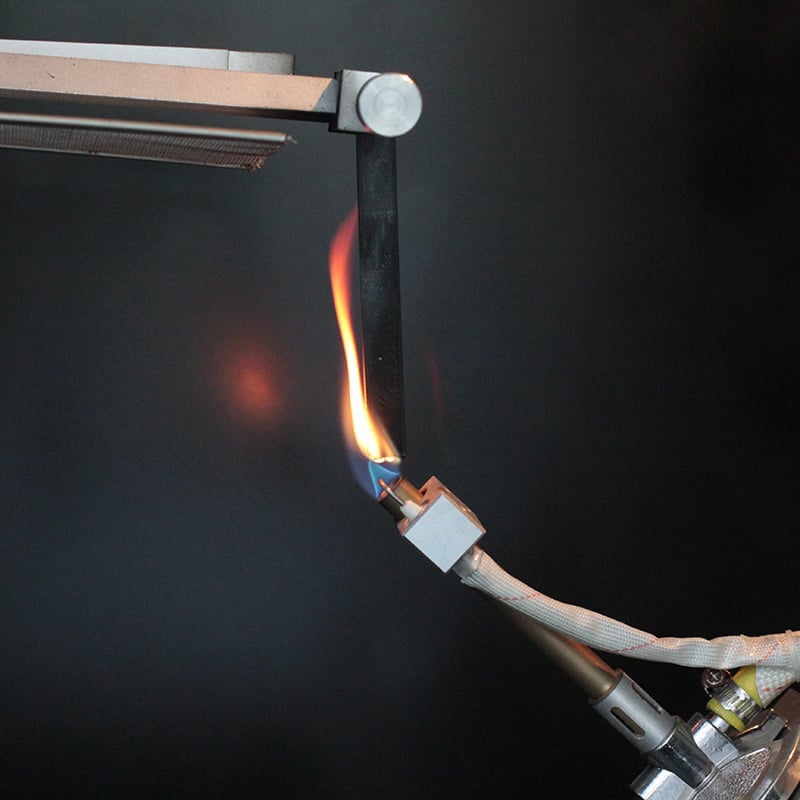

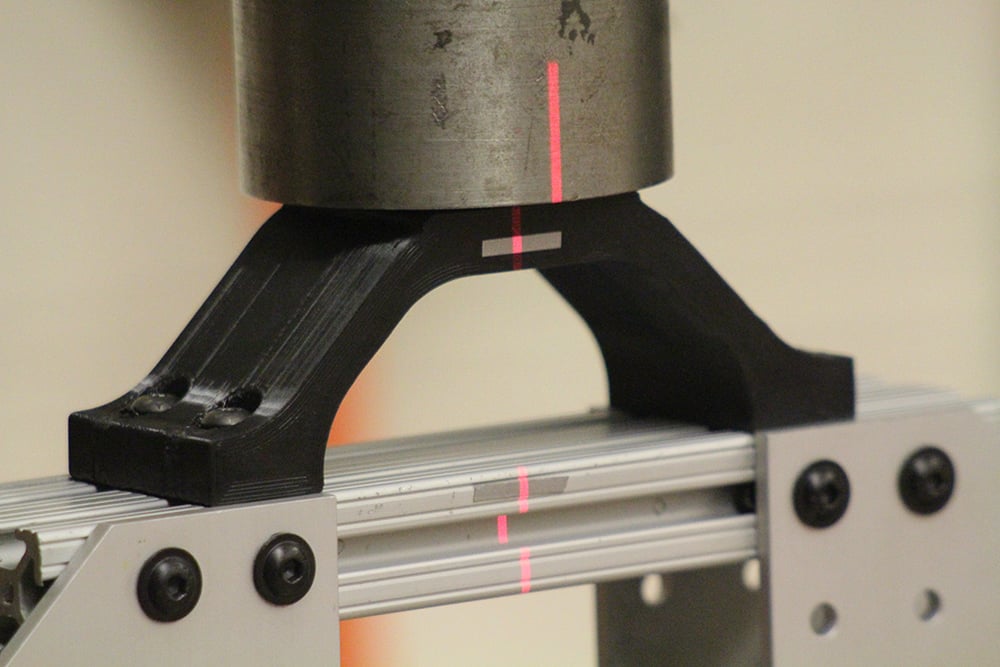

Wear Damage on the PolyMax™ PC drifting sleeves after intense usePoly

Wear Damage on the PolyMax™ PC drifting sleeves after intense usePoly