Why Polymaker

Our focus on innovation ensures we deliver the highest quality 3D printing materials to our customers. We back this up with excellent support services and technical help to enable you to print your parts with ease.

Simplify Creation

At Polymaker, we are committed to simplifying the creation process for everyone, from hobbyists to professionals. Our mission is to make 3D printing more accessible, user-friendly, and efficient by offering high-quality materials and hardware. We strive to develop innovative technologies that push the boundaries of 3D printing and enable users to bring their ideas to life with ease. Through our products, technical support, and educational resources, we aim to empower creators around the world to achieve their goals and unleash their creativity.

Sustainability

We believe that 3D printing is the best use of plastics in today’s society. Our vision is a future where additive plays a large part in the creation of consumer goods, localizing manufacturing and cutting transportation emissions. Our connectivity has the power to digitally spread files around the world, allowing one 3D printer to create an endless opportunity of ideas.

learn moreMilestones in Polymaker’s History

Products Timeline

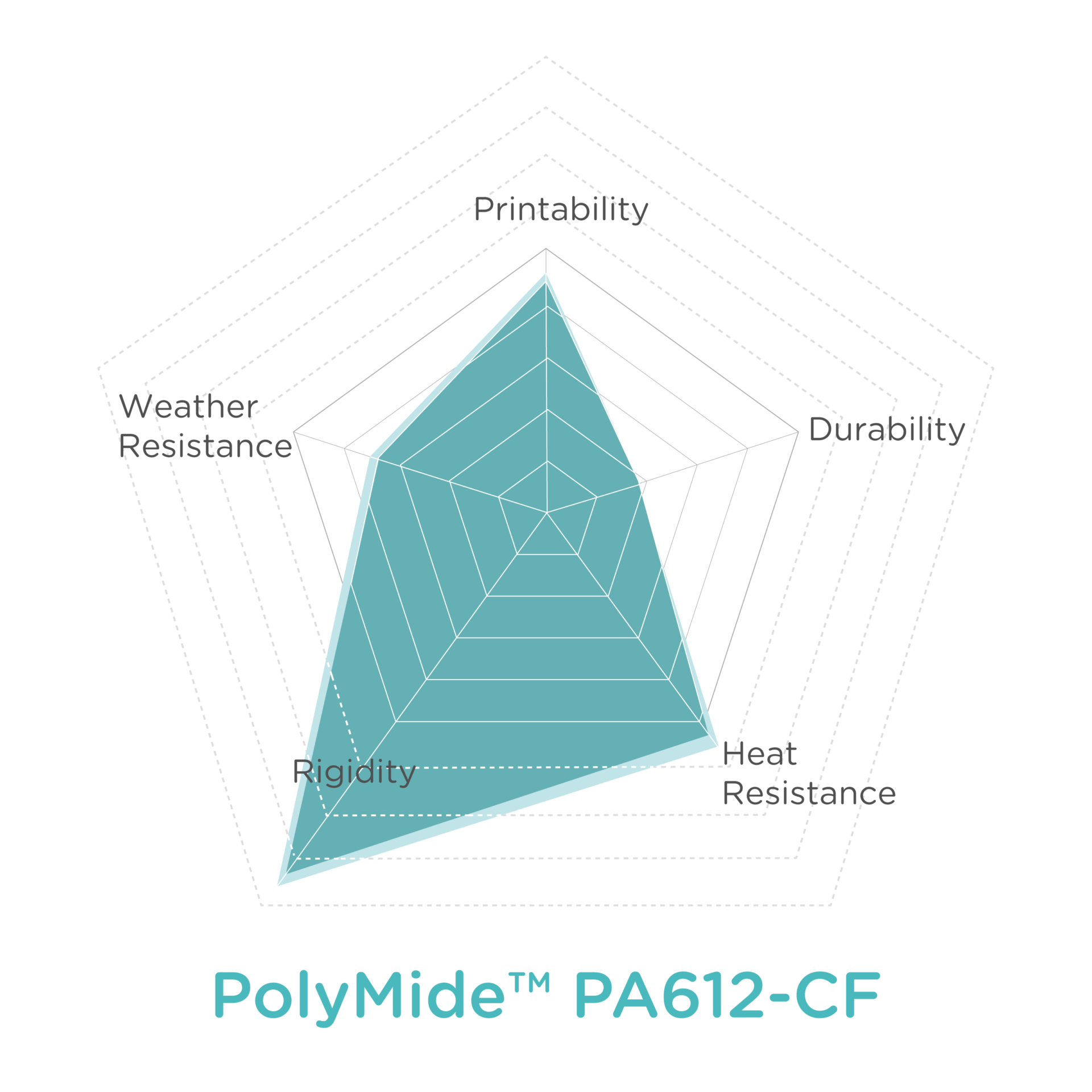

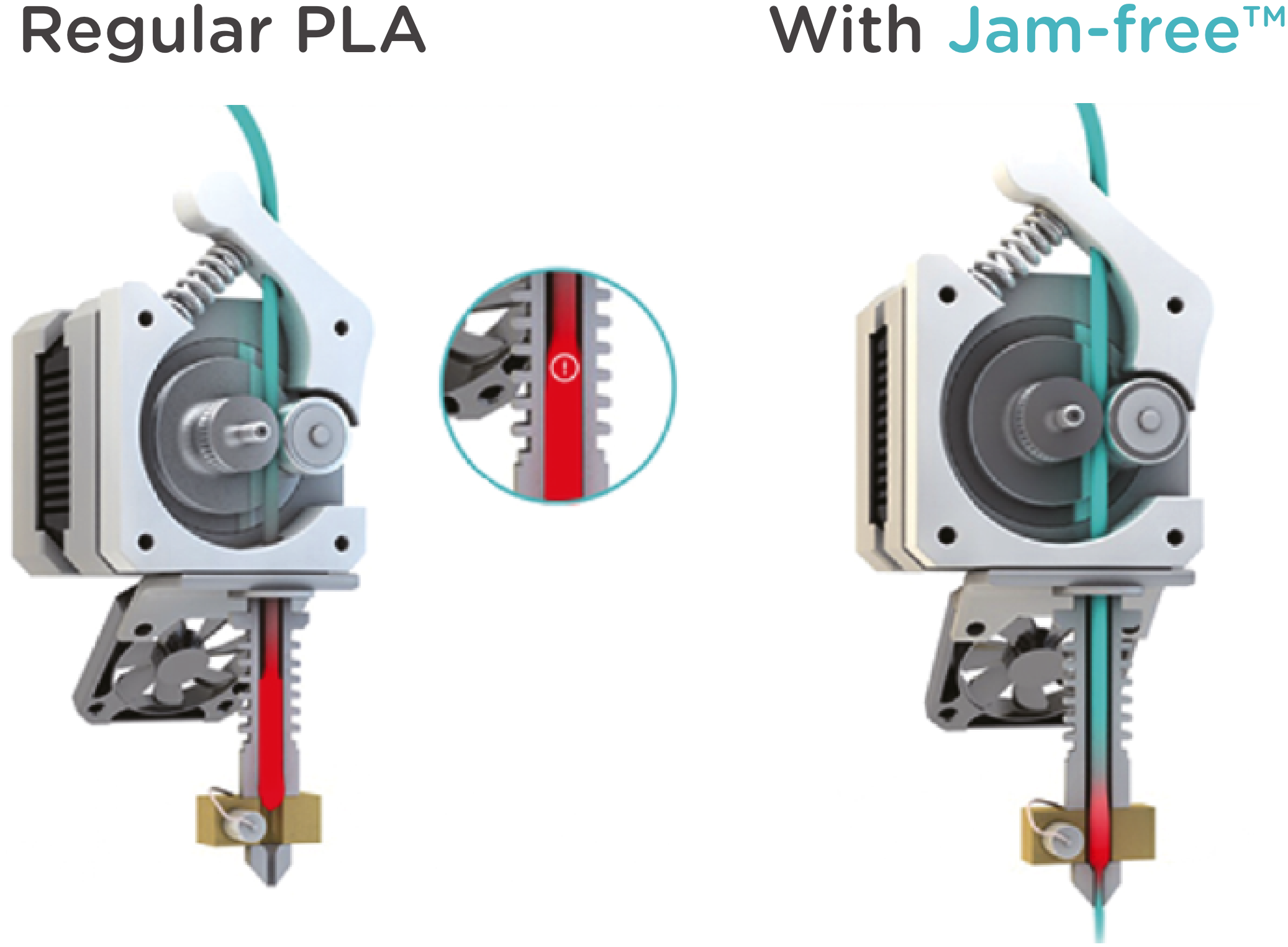

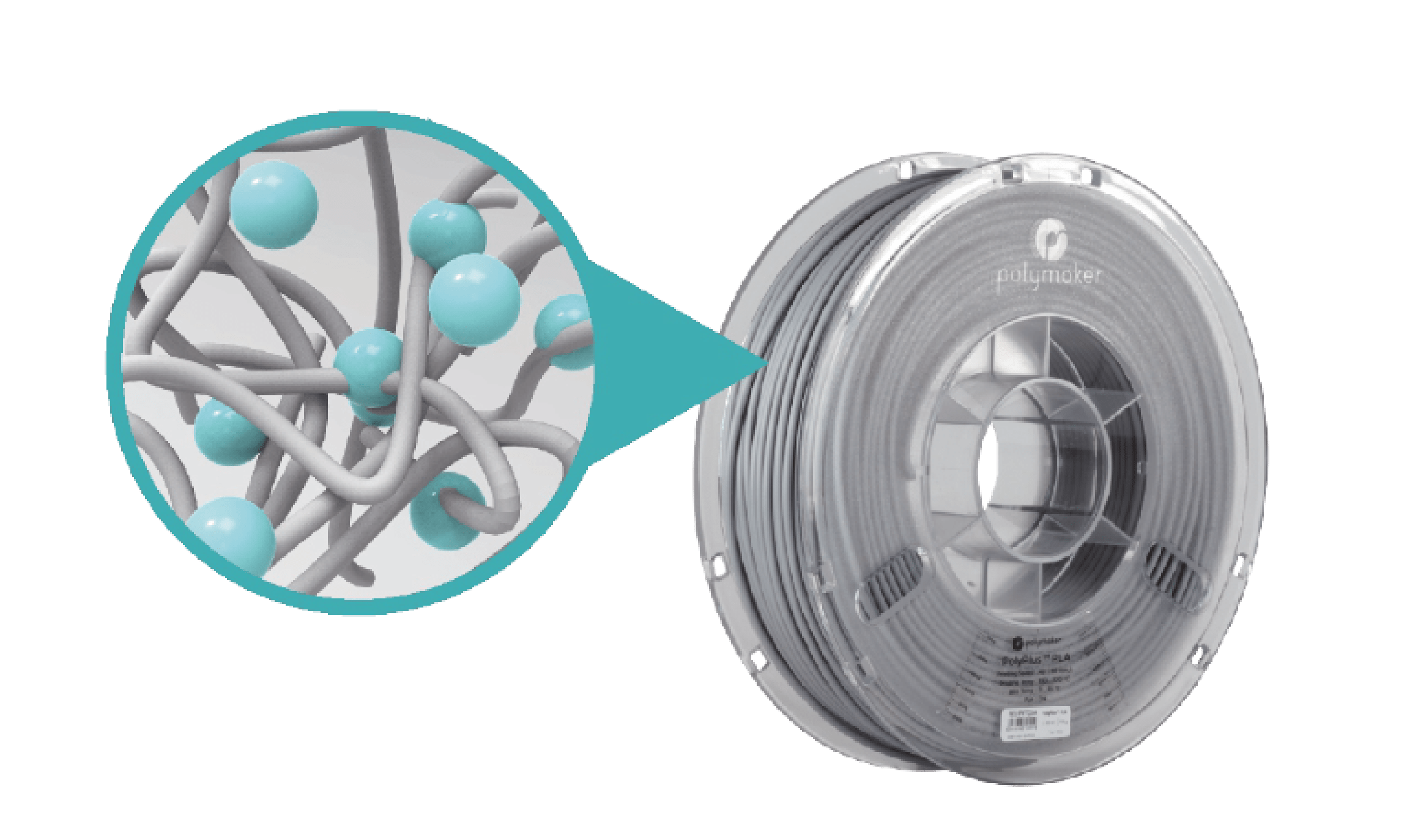

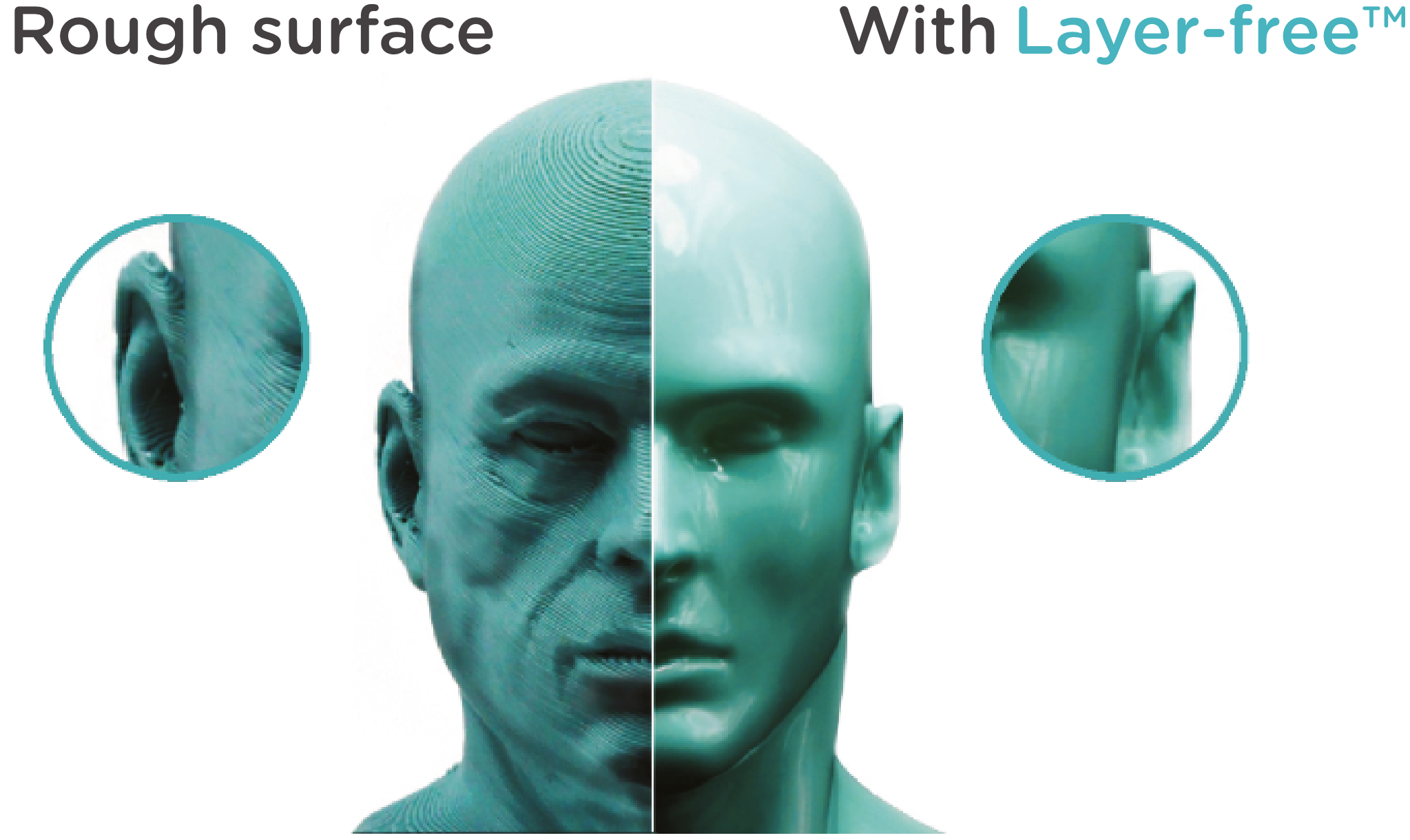

Key Technologies Developed by Polymaker

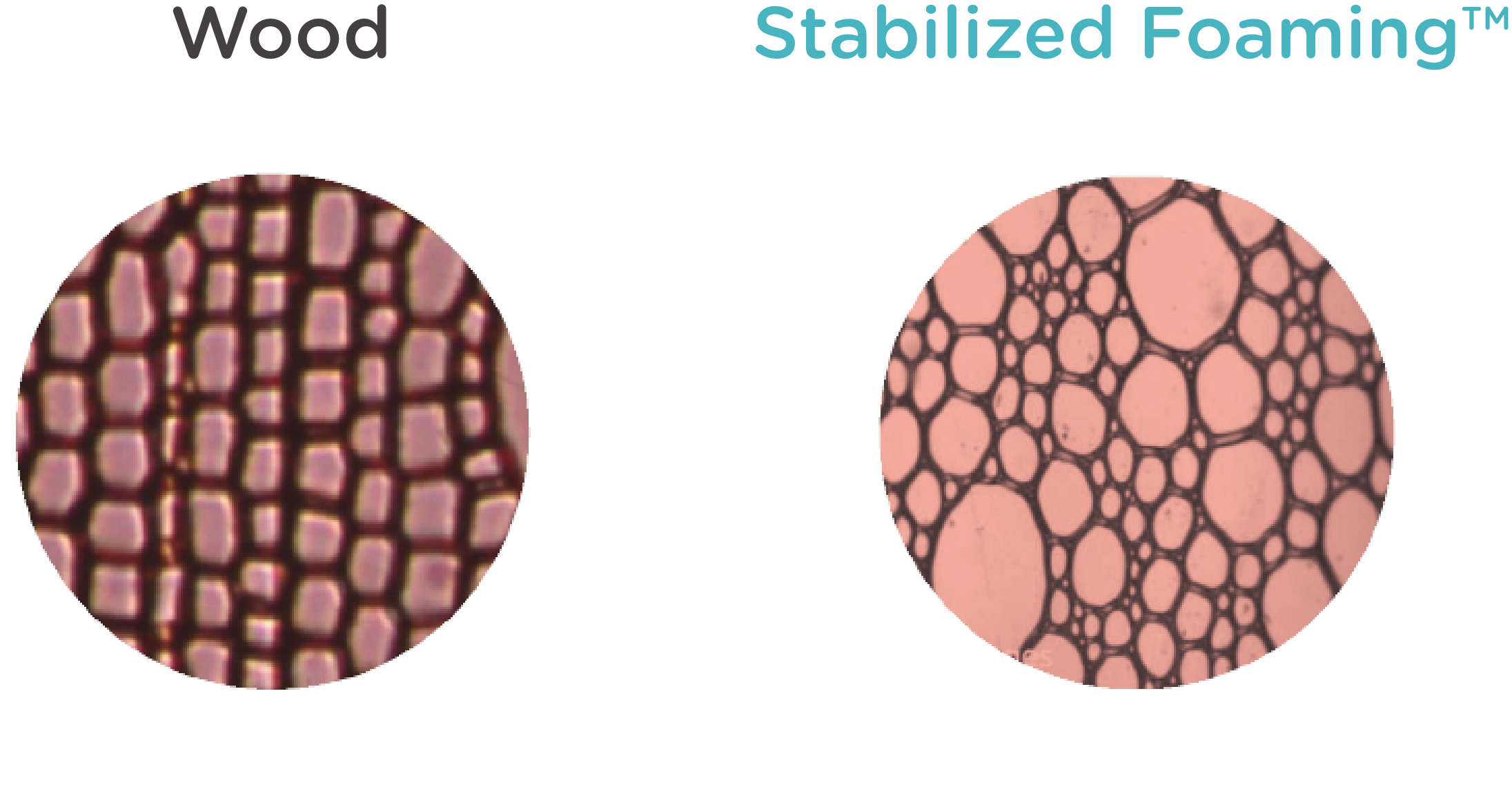

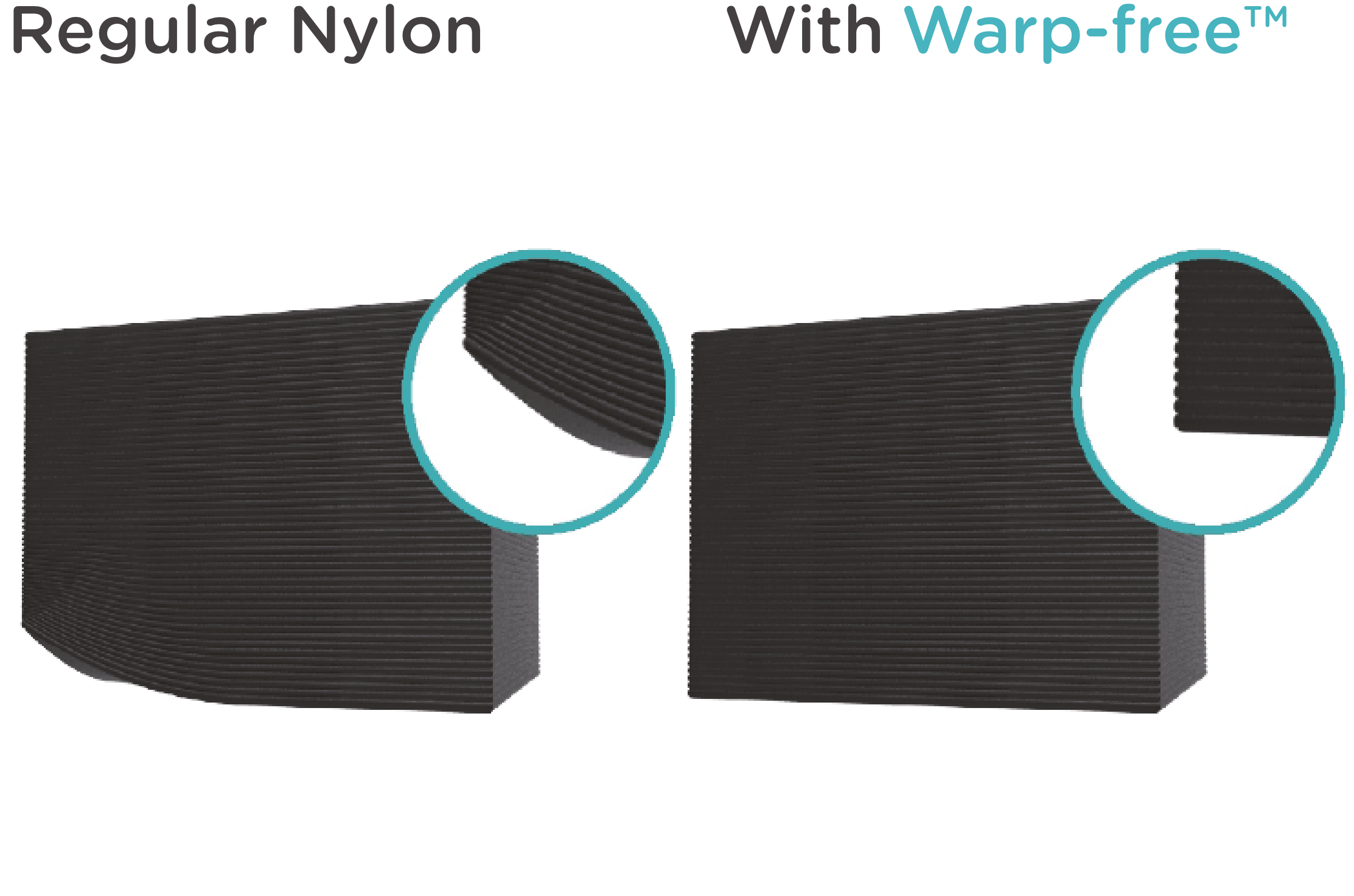

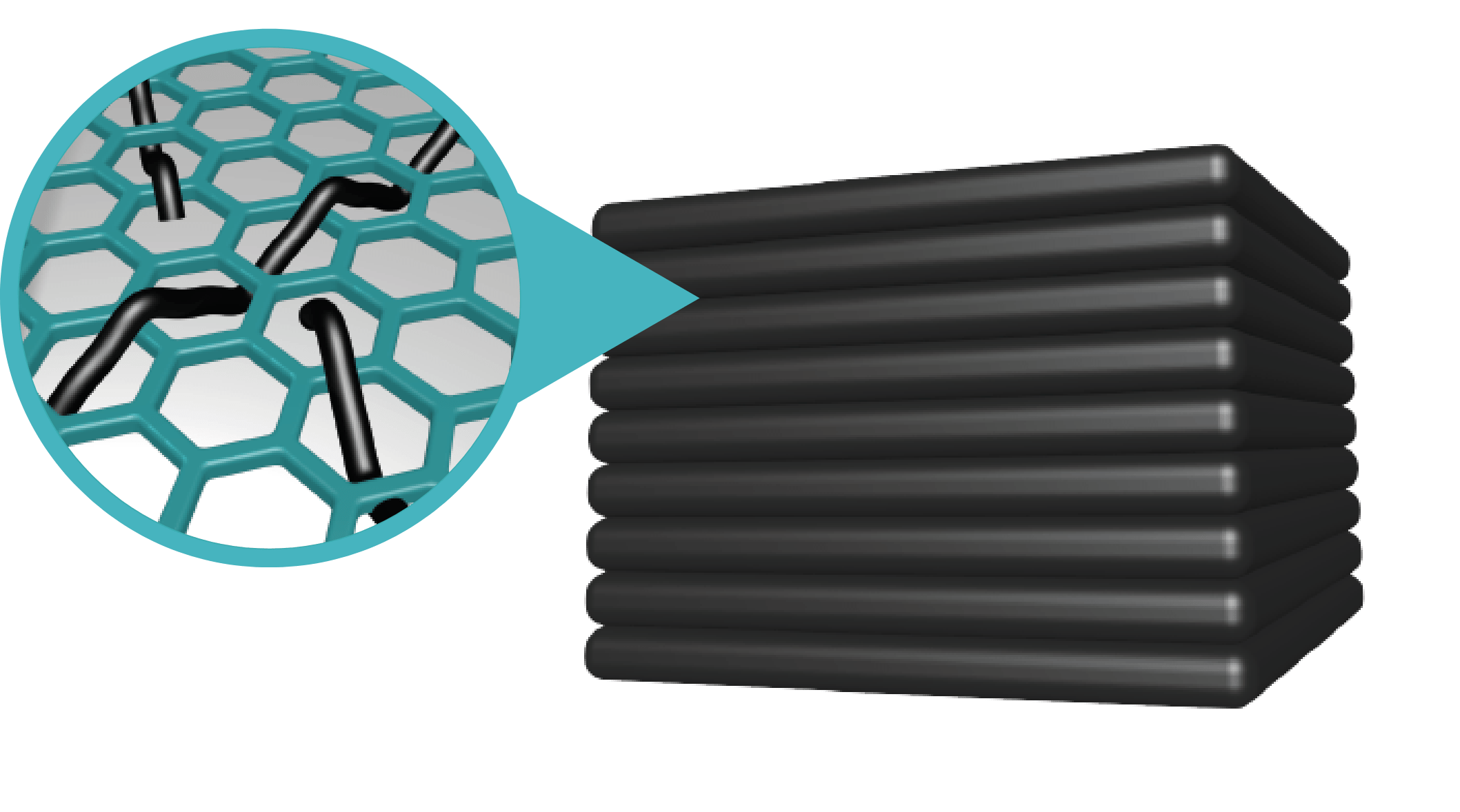

Polymaker has developed a number of cutting-edge technologies for 3D printing filament

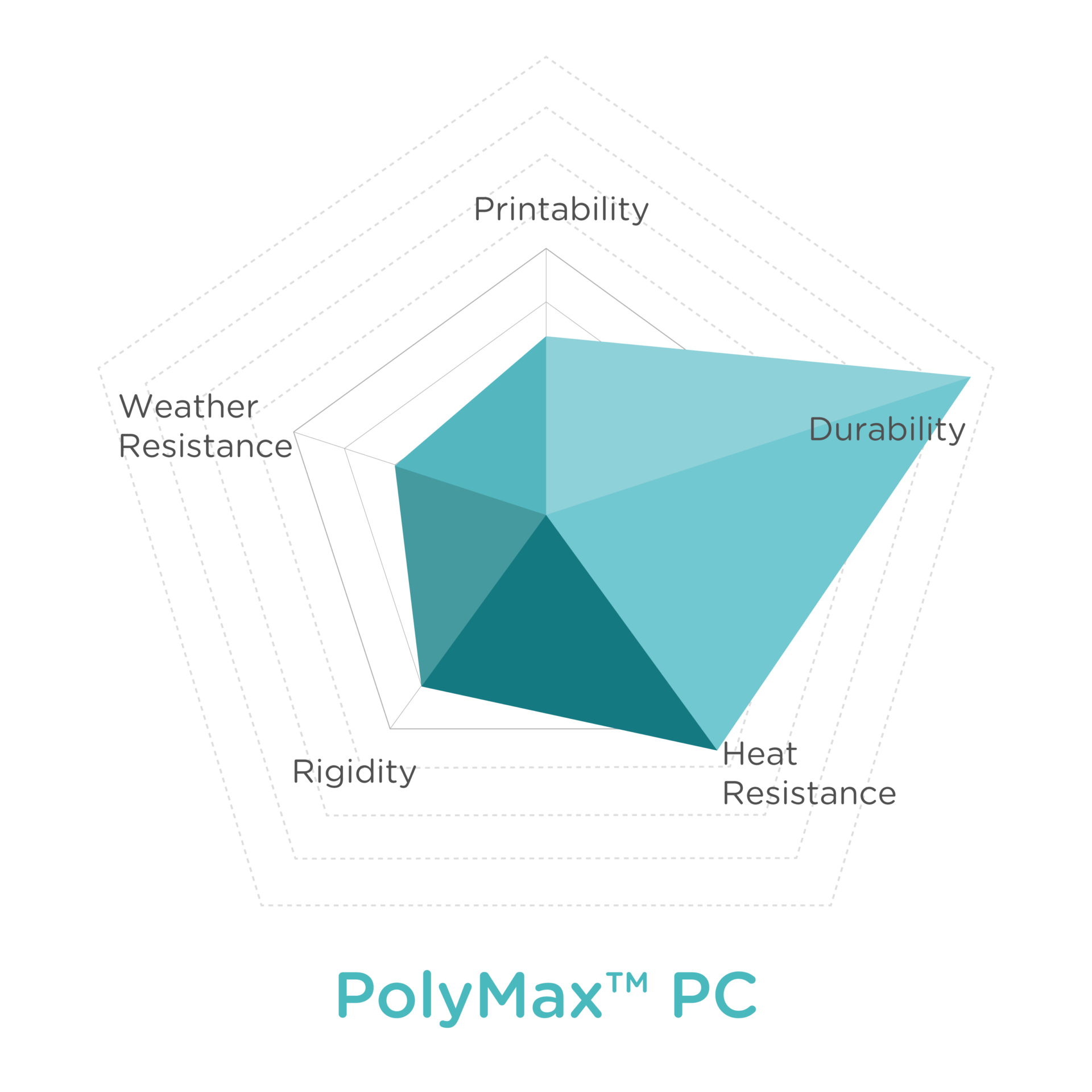

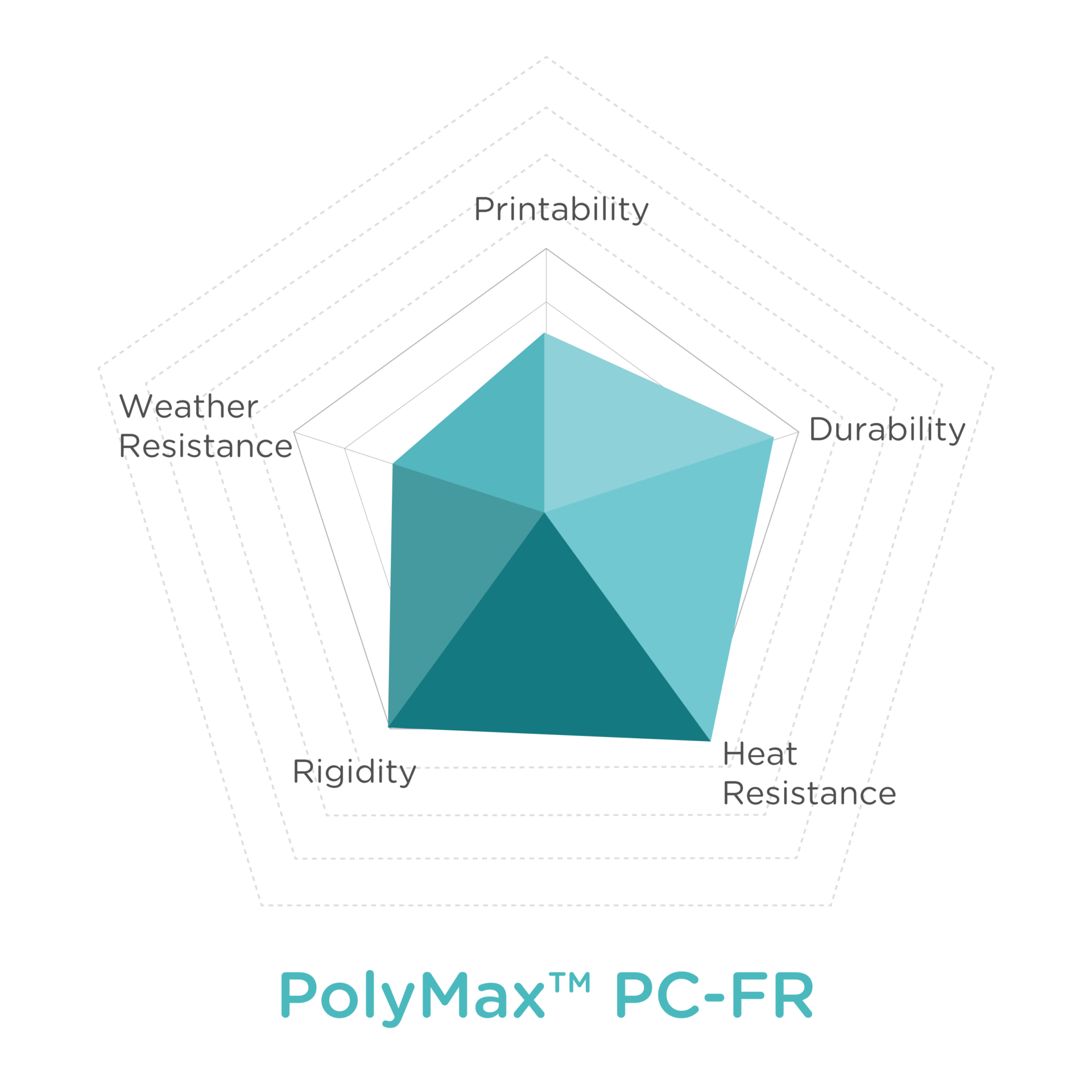

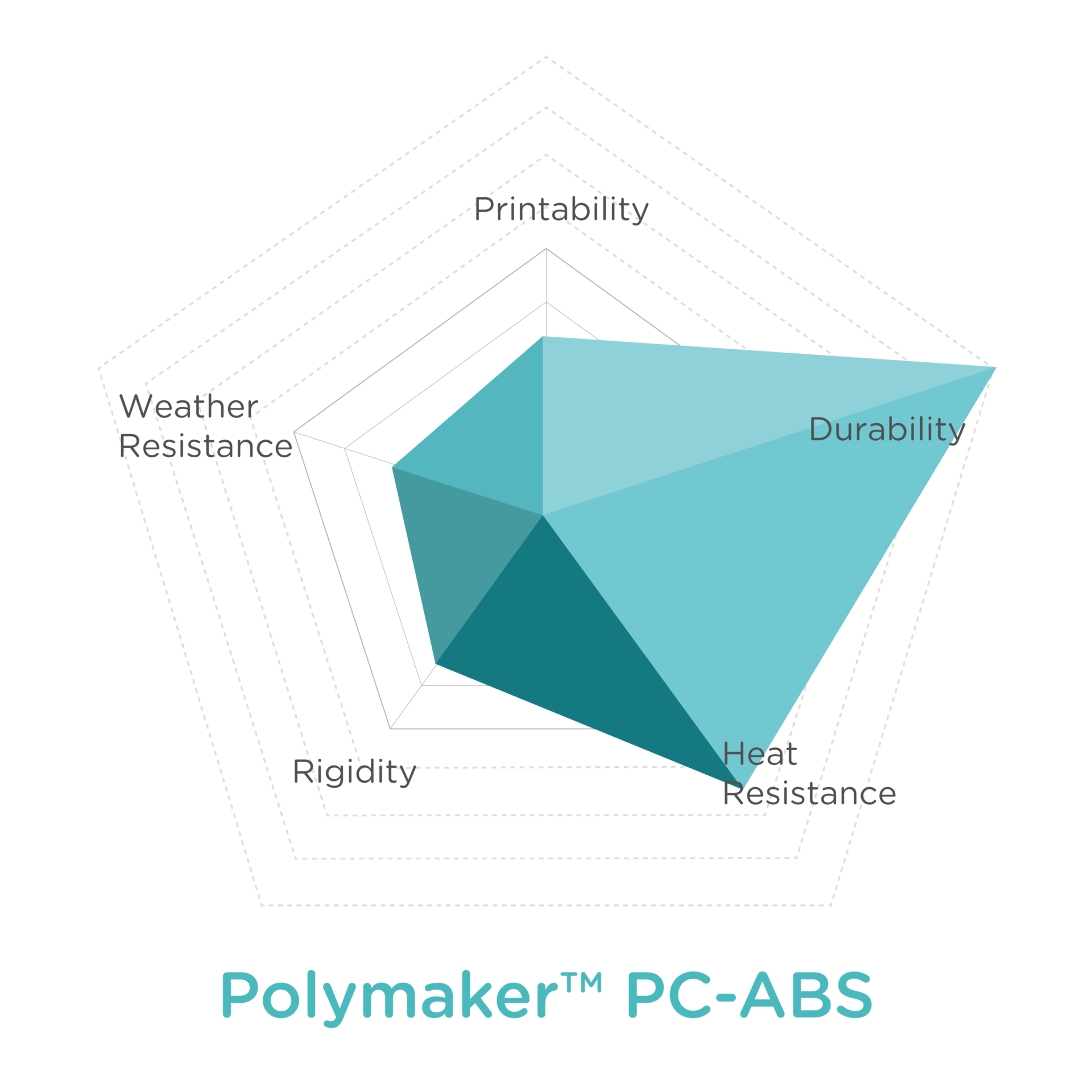

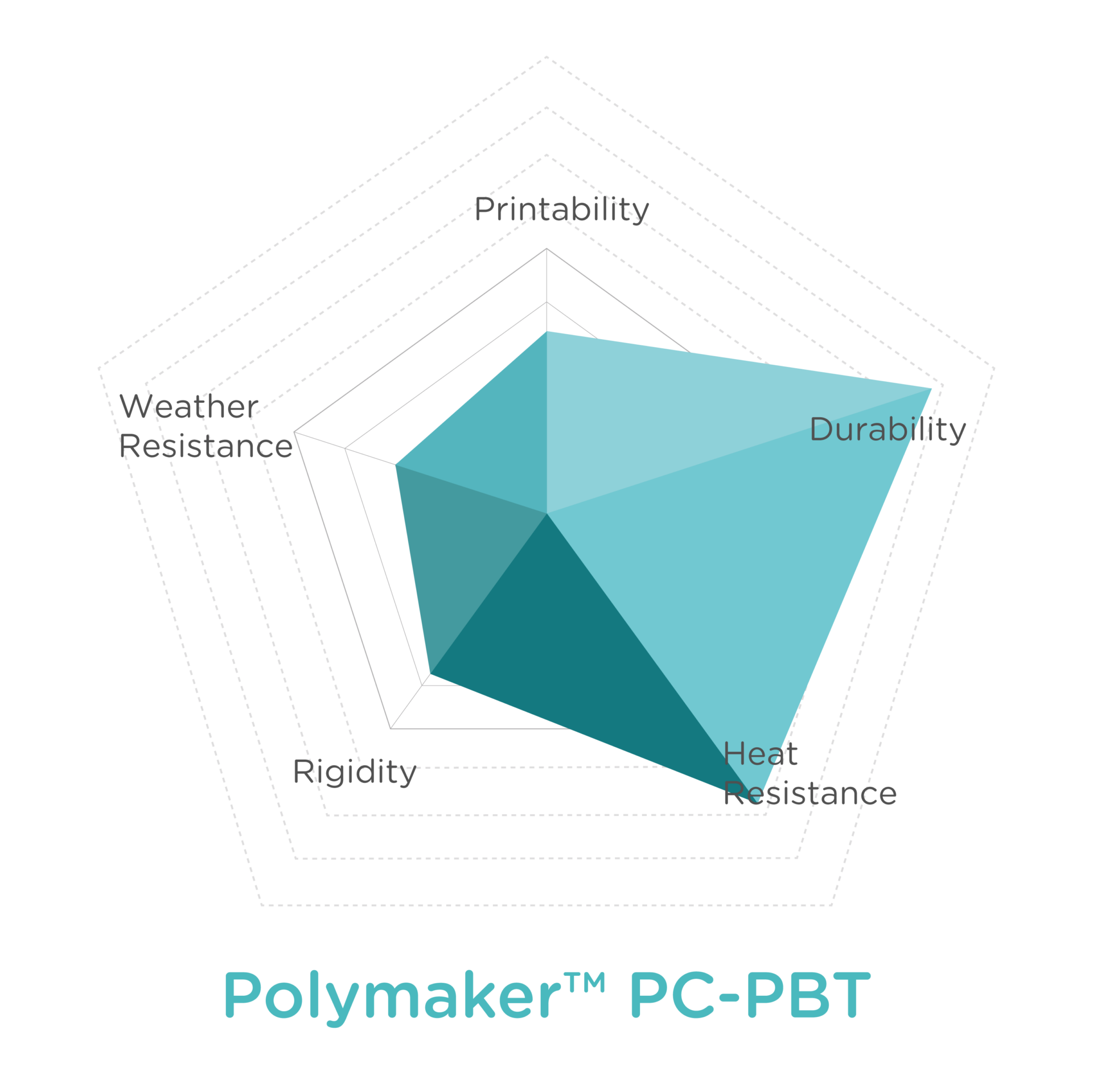

About Polymaker Industrial

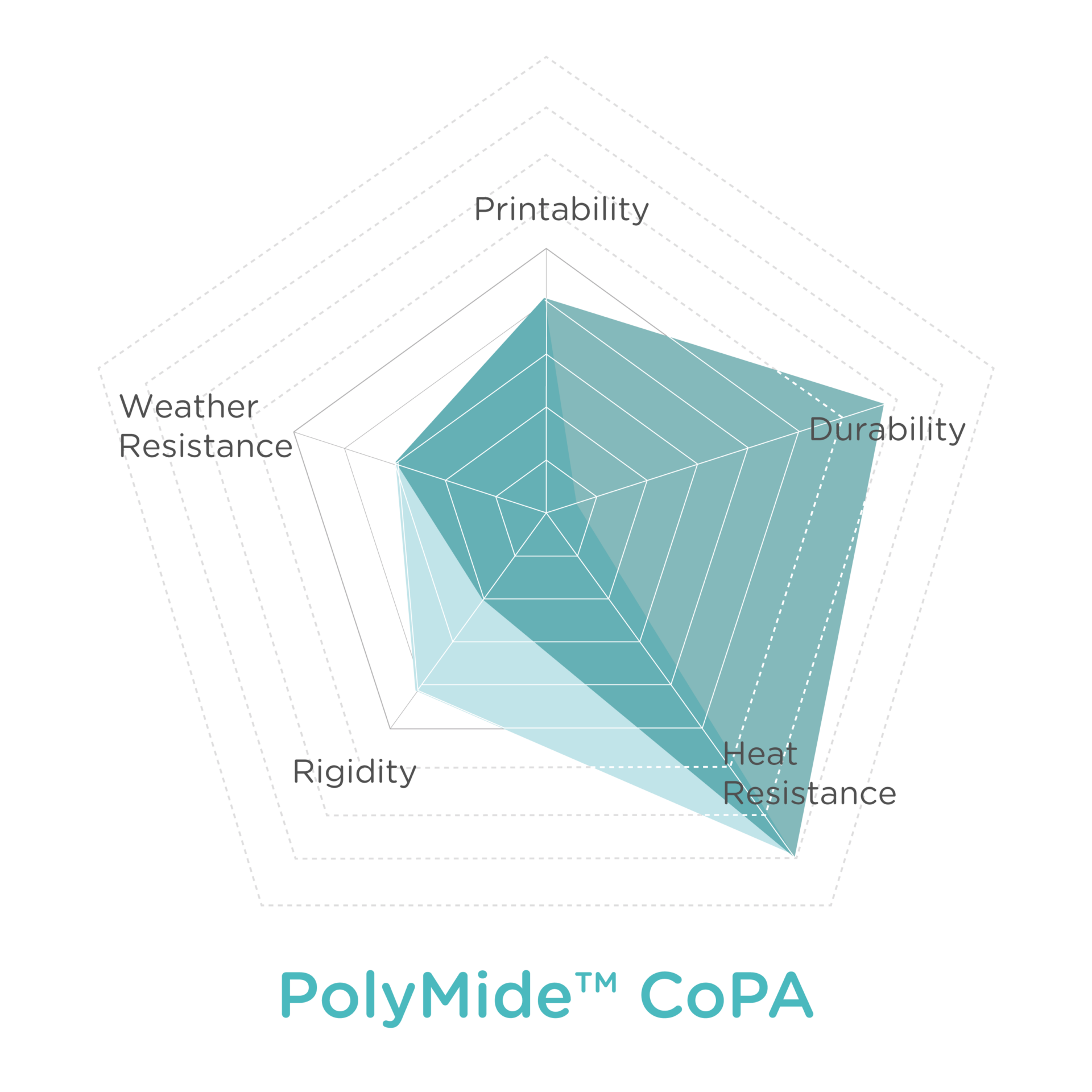

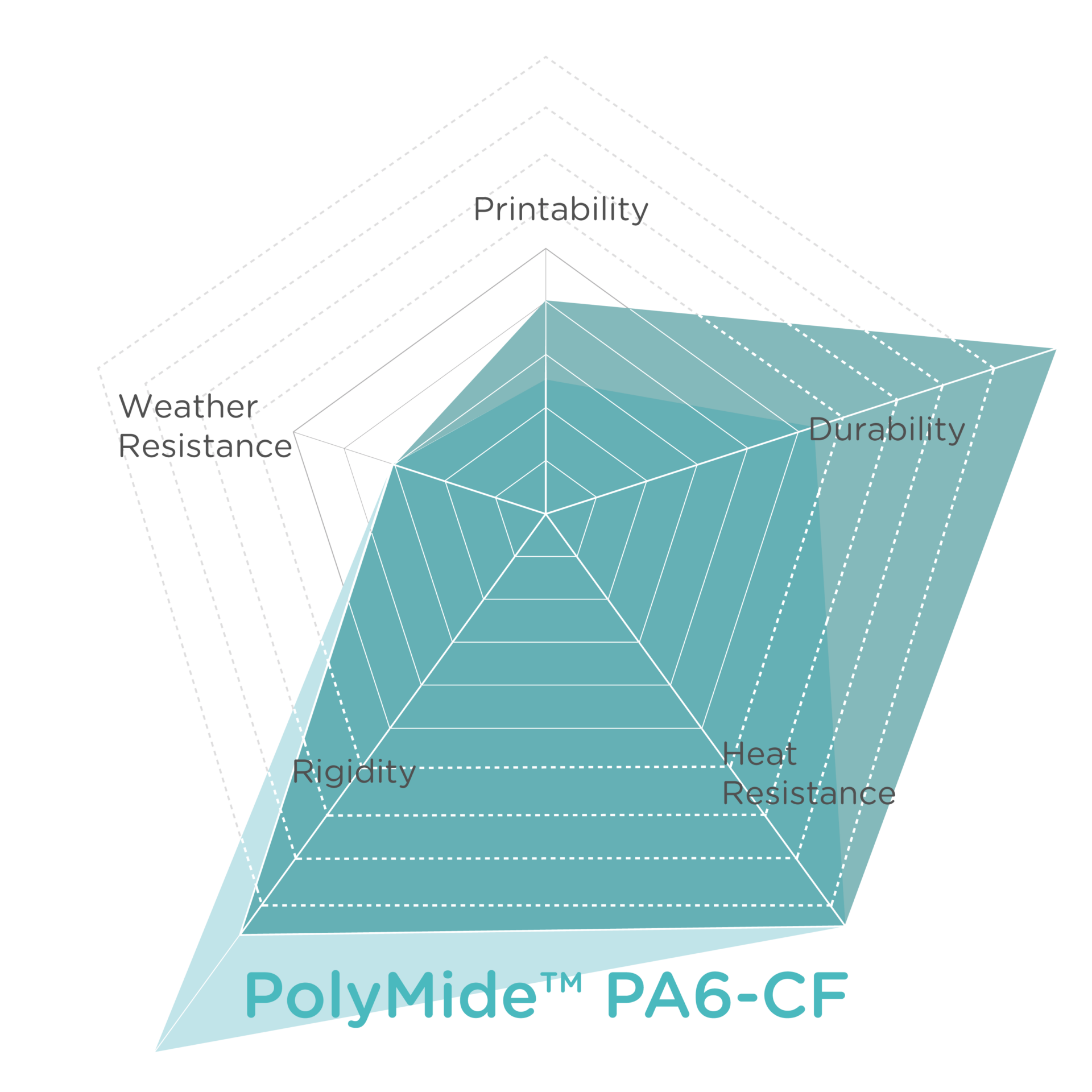

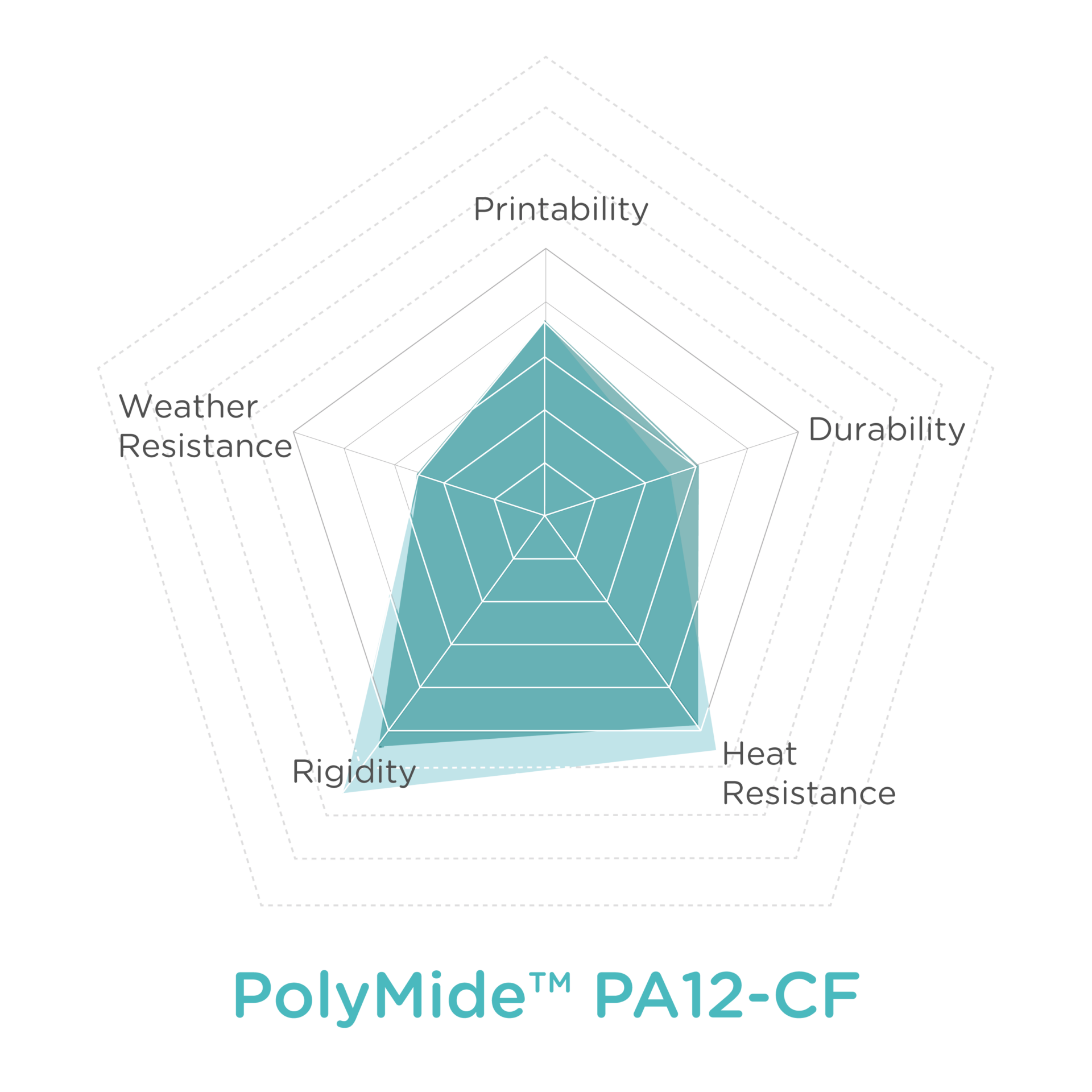

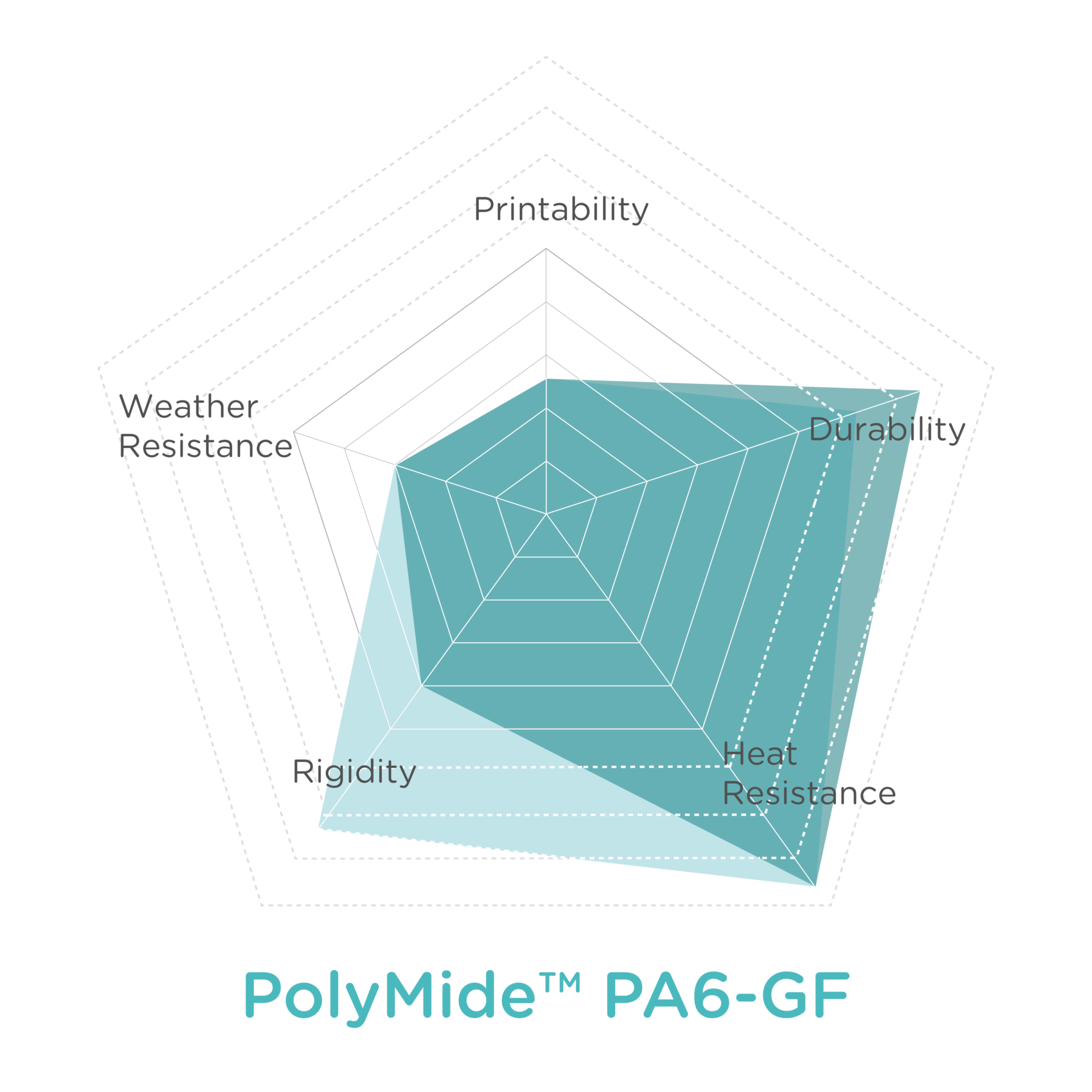

Polymaker Industrial is a series of engineering grade material solutions developed for the industrial 3D printing sector. Offering full customization of polymer compounds, Polymaker’s R&D scientists can tailor material characteristics to match your applications. Polymaker Industrial has an ever-growing portfolio of materials which enables customers to respond quickly to market needs. This includes offering small batch customized production and high-quality material solutions for high-temperature applications, flame retardancy, bio-compatibility, ESD and investment casting & moldings.

Our Support

Any questions about our products? Find answers in support center. Or contact us anytime through [email protected].

Over 100 Countries Individuals, Businesses and Organizations Trust Polymaker material extrusion based 3D Printing Material

Global Locations

Changshu (China)

Shanghai (China)

Houten (Netherlands)

Houston (USA)