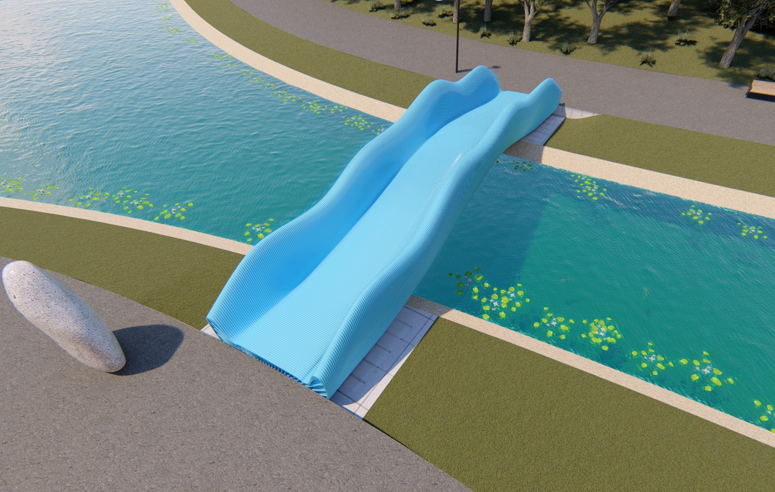

Polymaker unveiled the "Liuyun Bridge", a 3D printed polymer bridge built jointly by Shanghai Construction Group Co., Ltd., Polymaker, and Shanghai Kuying Technology Co., Ltd., in Yimahe Park, Longquanyi District, Chengdu in 2021. Inspired by the free-flowing shape of the stagecoach and dancing silk, “Liuyun Bridge” achieves bold innovations in landscape design using new technology and materials unlike ever before while managing to overcome many obstacles in the 3D printing process. Polymaker was largely responsible for the conception and completion of this project, providing the materials and spearheading the exploration of landscape bridge design.

The printing process of "Liuyun Bridge"

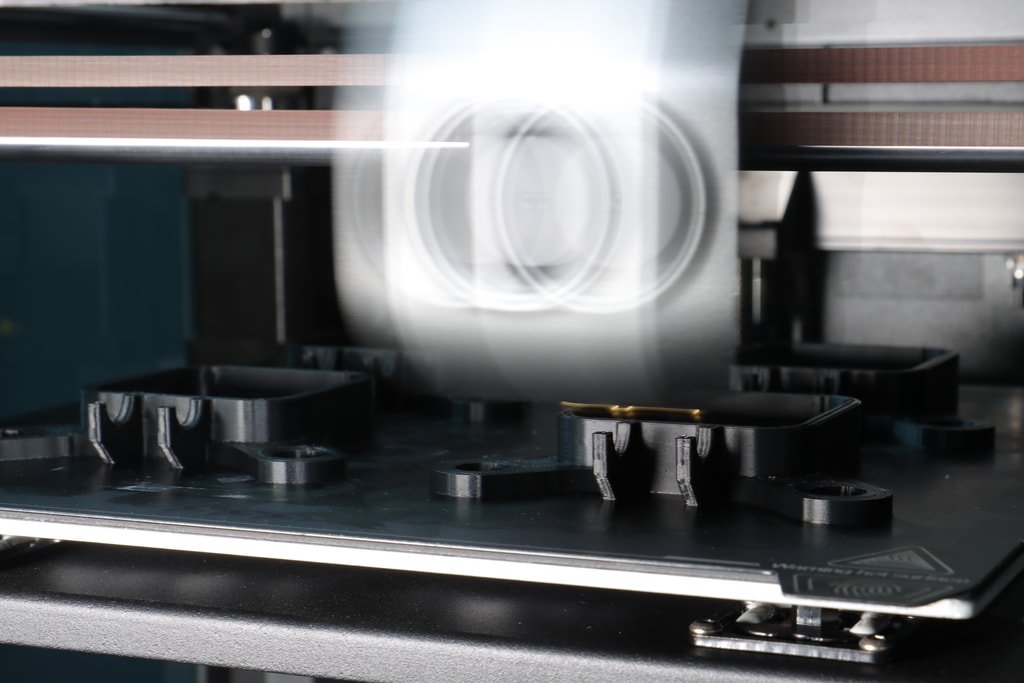

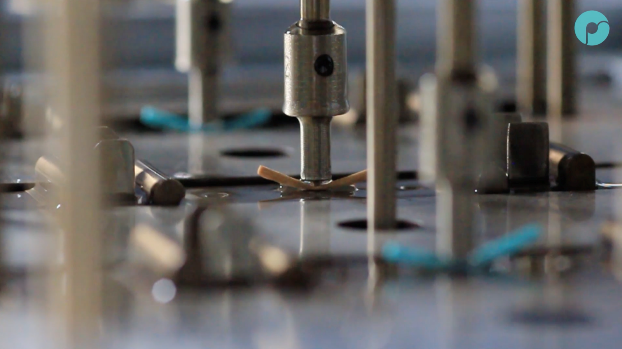

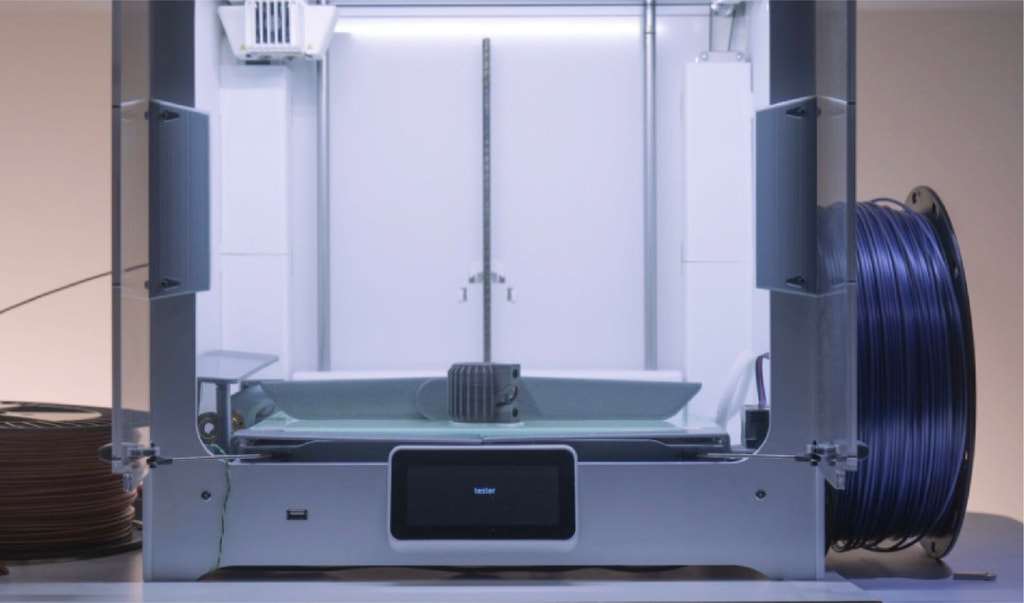

Innovating on the printing process, the “Liuyun Bridge” takes advantage of Polymaker’s materials and creatively employs new technology to complete its construction not only quicker, but also with higher quality. The bridge manages to shorten its construction period using the Kuying Tech’s 5-Axis Milling and Additive Manufacturing Integrated Machine (BGAM), which allows for uninterrupted 3D printing to continuously occur at all hours of the day without any manual interaction, finishing the printing of “Liuyun Bridge’s” main components in only thirty-five days.

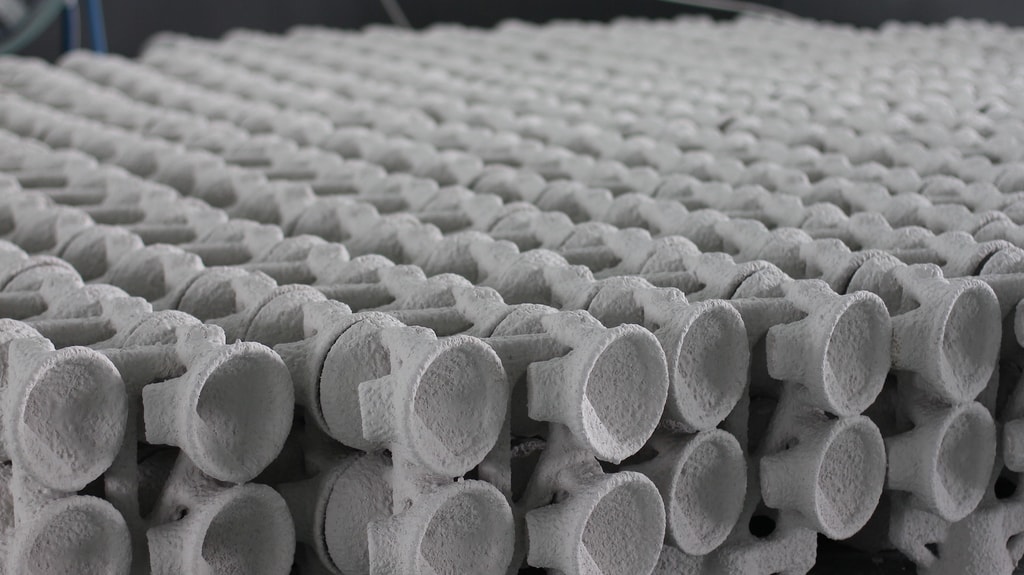

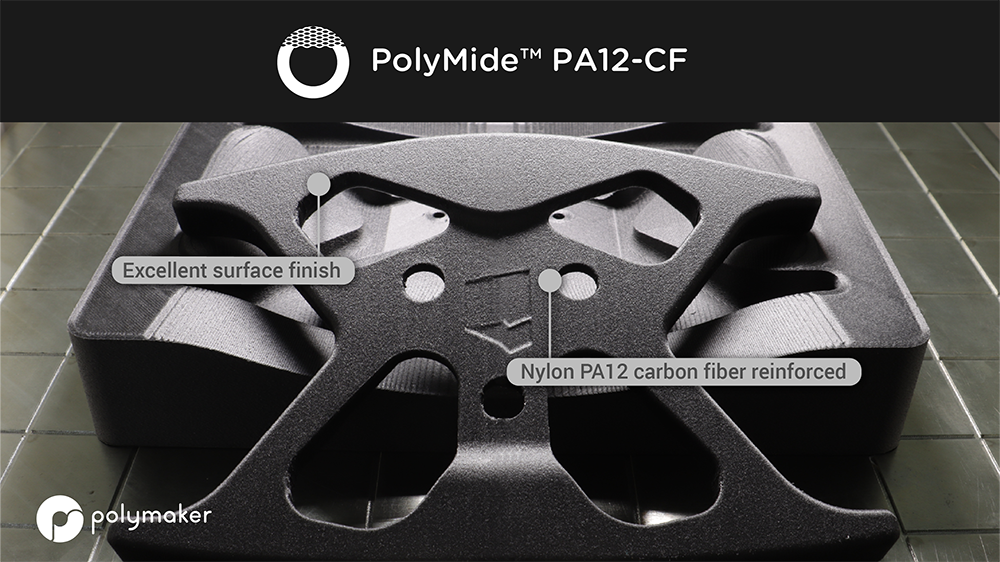

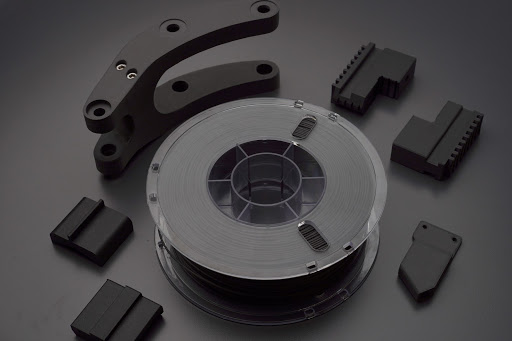

Polymaker guarantees the bridge’s stability and safety for years to come with their polymer pellets PolyCore™ ASA-3012, a material with excellent anti-aging. Another new method used to improve the printing process, closed-loop printing ensures there are minimal deformations by monitoring the temperature of the material during the printing process. The “Liuyun Bridge” consumes several tons of materials to finally complete its construction by printing segmented components to be assembled on site. Heavily dependent on Polymaker and their materials, “Liuyun Bridge” is a one-of-a-kind landscape bridge that only found its success through Polymaker.

A tremendous feat for 3D printing like the “Liuyun Bridge” never could have been accomplished without the collaboration between Shanghai Construction Group Co., Ltd., Polymaker, and Shanghai Kuying Co., Ltd. The actual design for the bridge was a product from both Shanghai Construction Group Co., Ltd. and Polymaker while Shanghai Kuying Co., Ltd. was responsible for the technology that let the material reach its fullest potential, crafting the bridge’s components with few errors and in an extremely short amount of time. However, Polymaker’s PolyCore™ ASA-3012 laid the foundation for this incredible achievement in 3D printing as the material made the design feasible in reality and continues to support its everyday use.

Materials used for “Liuyun Bridge”

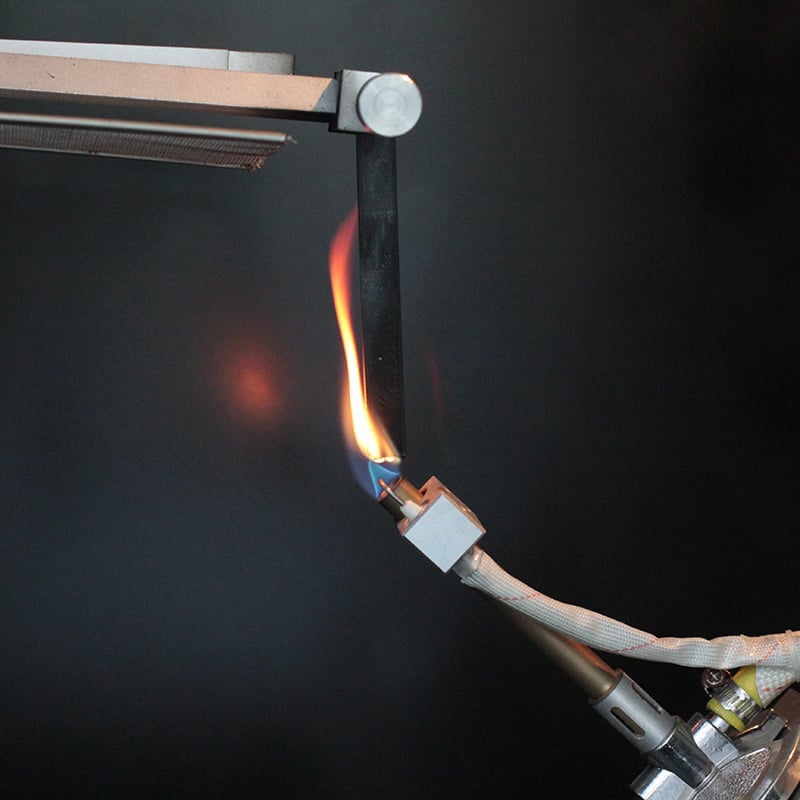

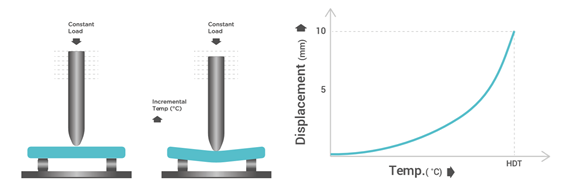

The “Liuyun Bridge” used many new methods specific to Polymaker’s material to expand on the bridge’s performance. As the optimal material for the bridge, PolyCore™ ASA-3012 has mechanical properties suited for outdoor use and works specifically for large 3D prints, enhancing their dimensional stability and interlayer adhesion. Currently, most additive manufacturing technologies result in residual stress and warpage when using the fused deposition molding process. However, “Liuyun Bridge” incorporates a multi-factor analysis method, controlling ambient temperature and the three-stage melting of materials with different parameters like temperature, glass transition temperature, and single-layer printing time, to prevent any warping or deformations caused by rapid cooling.

During the printing process, heating the workspace before and after printing strengthens the layer-by-layer adhesion of the 3D printed materials, further reducing any possible problems with the printed components. Allowing the design of “Liuyun Bridge” to be fully realized, the high-precision five-axis CNC processing system of Kuying’s BGAM removes the typical margin of error reserved for printing deformations and heightens the accuracy of segmented printing components. With Polymaker’s PolyCore™ ASA-3012 being so advantageous, it solves many previous printing issues while still bolstering “Liuyun Bridge’s” stability and structure.

“Liuyun Bridge” is not the first bridge to use 3D printing technology though. Polymaker has worked in the construction of a few other 3D printed bridges, both at home and abroad, to realize new breakthroughs and accomplishments on each of their projects.

Polymaker’s 3D printed bridges in China

Shanghai Taopu Central Park Bridge

In 2019, China’s first composite landscape bridge was constructed in Shanghai Taopu Central Park by Shanghai Construction Group Co., Ltd., Polymaker, and Shanghai Kuying Technology Co., Ltd. As the first composite landscape bridge with one-time molding and a multi-dimensional curved surface, the Taopu Central Park Bridge breaks through the shackles of traditional bridge design and frees the landscape bridge to be more flexible and diverse in space. Like with “Liuyun Bridge”, the Taopu Central Park Bridge owes its conception and dynamic shape to Polymaker and their materials.

The printing process of this 3D printed landscape bridge went through nearly one hundred printing tests to be continuously optimized. The super-large gantry 3D printer, jointly developed by Shanghai Construction Group Co., Ltd. and Kuying Technology Co., Ltd., allows for more diverse printing of larger sizes while still improving the printing’s accuracy. The Taopu Central Park Bridge is also composed of Polymaker's PolyCore™ ASA-3012 material, so the bridge can withstand long-term exposure to the sun and rain.

Quanzhou Bridge

Polymaker installed China’s second 3D printed bridge in the ecological belt of Baiqi Lake in Quanzhou, Fujian in 2019 as the second collaboration between Shanghai Construction Group Co., Ltd., Polymaker, and Shanghai Kuying Technology Co., Ltd. Spanning 17.5 meters, the Quanzhou Bridge also uses Polymaker’s PolyCore™ ASA-3012 material for its body and drastically improves on the manufacturing time of traditional concrete grouting, completing its construction in only five weeks.

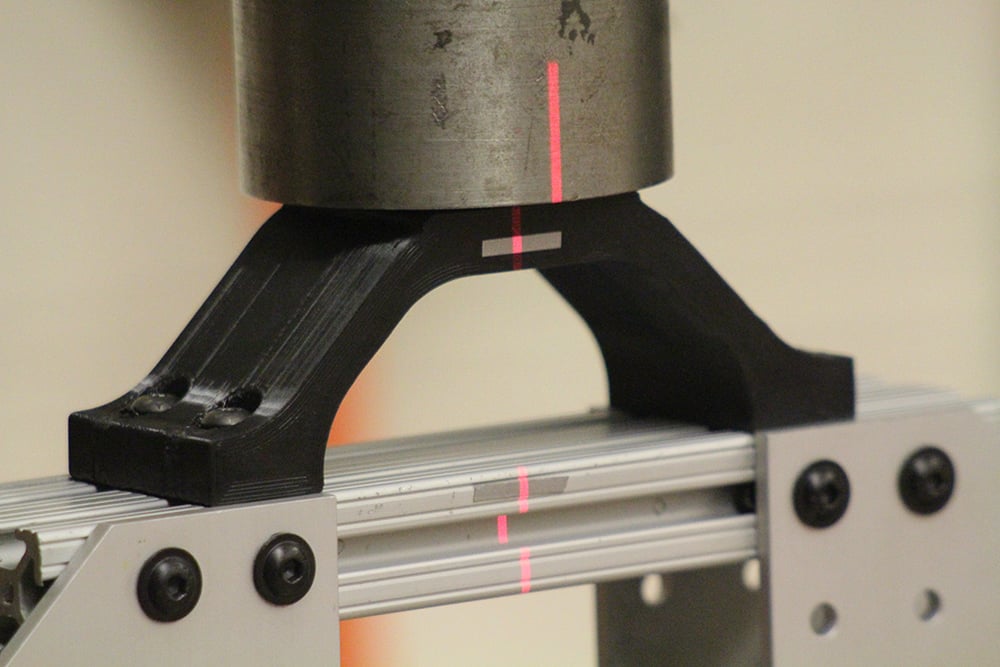

With the bridge’s manufacturing saving a considerable amount of time, it continues to compete with traditional grouting by providing strength that can withstand a pressure of two kilonewtons for each square meter, guaranteeing its ability to carry any amount of traffic. The Quanzhou Bridge utilizes a segmented design, unlike the Taopu Central Park Bridge, allowing its segments to be connected through a unique link mechanism to meet necessary mechanical requirements. Together, Polymaker's PolyCore™ ASA-3012 and the BGAM print the different components of the bridge to be assembled and painted for the finished construction, like with the printing process of the “Liuyun Bridge”.

The future of 3D printed bridges

Polymaker plays a role throughout the entire process of their 3D printed landscape bridges, covering many different facets from modeling, construction, and conception to data design. 3D printing technology truly emphasizes the "link of artistic inspiration with the power of science and technology" by pushing both sides to reach a product that stands above expectations. Polymaker’s application of 3D printing technology in landscape design greatly expands opportunities for technological innovation and exploration in the industry.

With 3D printing technology only continuing to grow, it has become an important consideration in constructing footbridges and large-sized printing quicker, with more cost effectiveness, and in a sustainable manner. Large-sized printing solutions are becoming more and more popular in different fields too, and Polymaker wants to fuel their growth by actively developing and producing materials that can bring ambitious projects to reality.

Without the material Polymaker has been creating, 3D printed bridges would never be as developed as they are now because Polymaker’s material not only provides the flexibility to meet any design’s needs, but also the strength to sustain the bridge for many years. Polymaker advances the world of 3D printing in more ways than only with their materials though. Their passion to push the industry and venture into unexplored territory has given 3D printing new capabilities and unimaginable possibilities.

Shanghai Construction Group Co., Ltd.:

Shanghai Construction Group Co., Ltd. is a leading enterprise in China's construction industry, ranking among the world's top 500 companies. Over the past sixty years, Shanghai Construction Group Co., Ltd. has repeatedly set records in the history of engineering construction in China and even in the world. It has contributed to many excellent projects in more than 100 cities across the country and in more than 30 countries and regions around the world. In recent years, Shanghai Construction Group Co., Ltd. has made every effort to promote national development, strengthen the synergy of the entire industry chain, and continue to form new commanding heights in business areas such as urban renewal, water conservancy, environmental governance, digital industrial construction, and construction services. They are now accelerating construction to become a widely acclaimed service provider for the whole life cycle of construction.

Shanghai Kuying Technology Co., Ltd.:

Shanghai Kuying Technology Co., Ltd. is a high-tech enterprise specializing in the research and development of super-large 3D printing solutions. The company adheres to the concept of "exploring future manufacturing methods" and is based on the innovative model of "integration of addition and reduction of materials, research and development of new materials, and intelligent control" in order to help manufacturing companies reduce costs and improve efficiency. The company’s existing intelligent equipment products include the Tech’s 5-Axis Milling and Additive Manufacturing Intergrated (BGAM), the high-speed pellet printer (SGAM), and the robotic additive manufacturing system (BRAM). These main products are widely used in architectural landscape, aerospace, shipbuilding, rail transit, energy, automobiles, medical products, and many other industries.