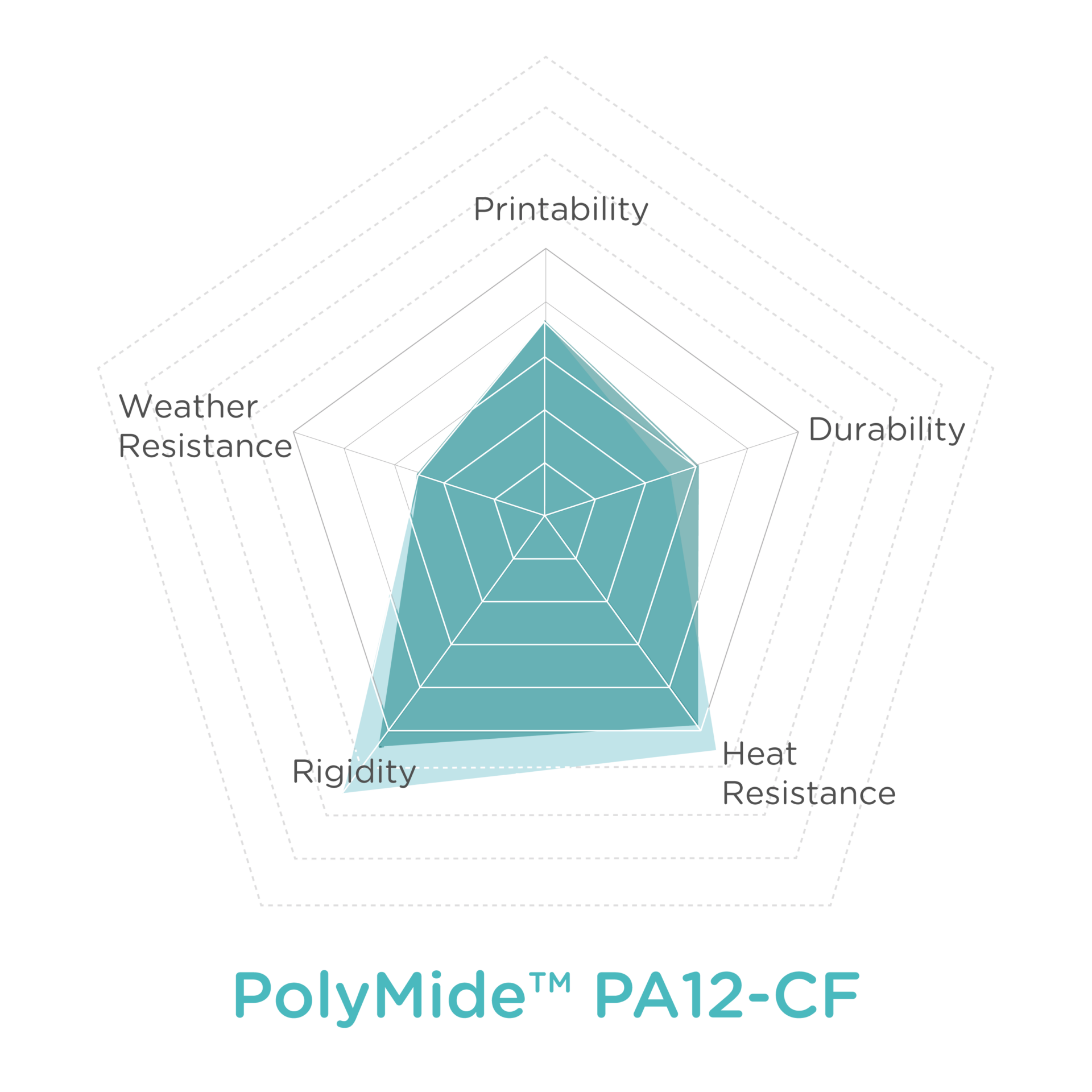

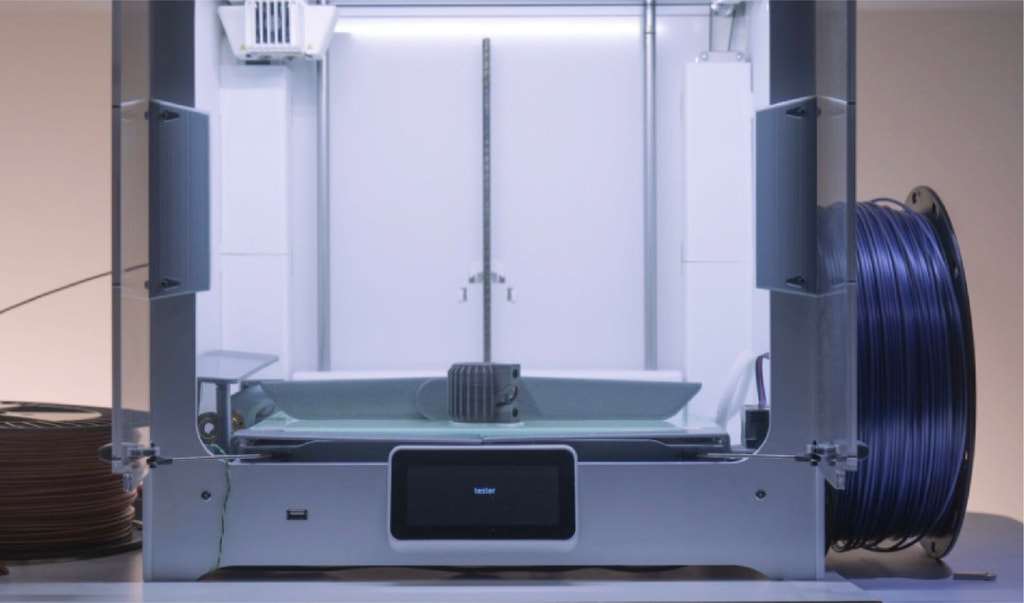

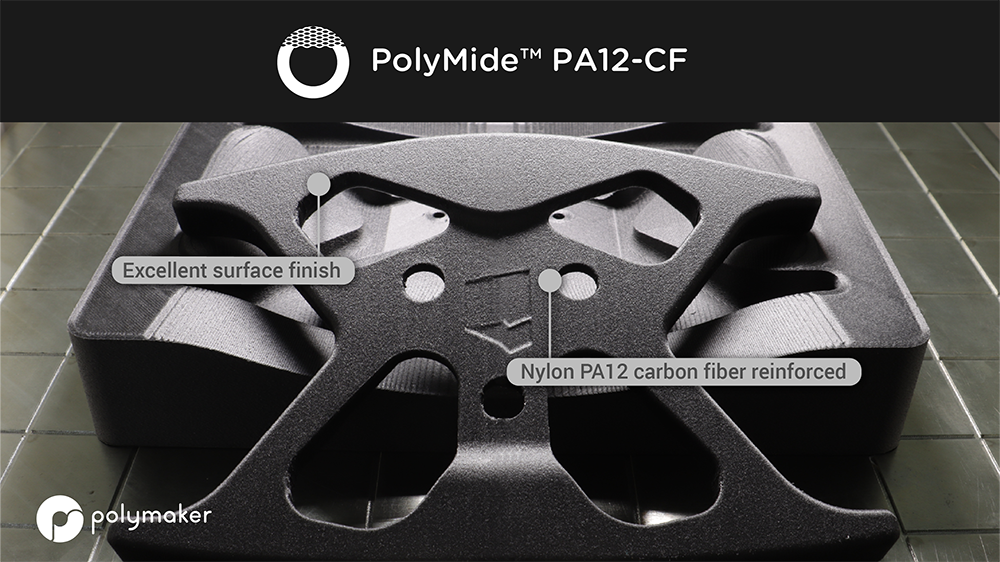

PolyMide™ PA12-CF: High stability nylon filament for 3D printing

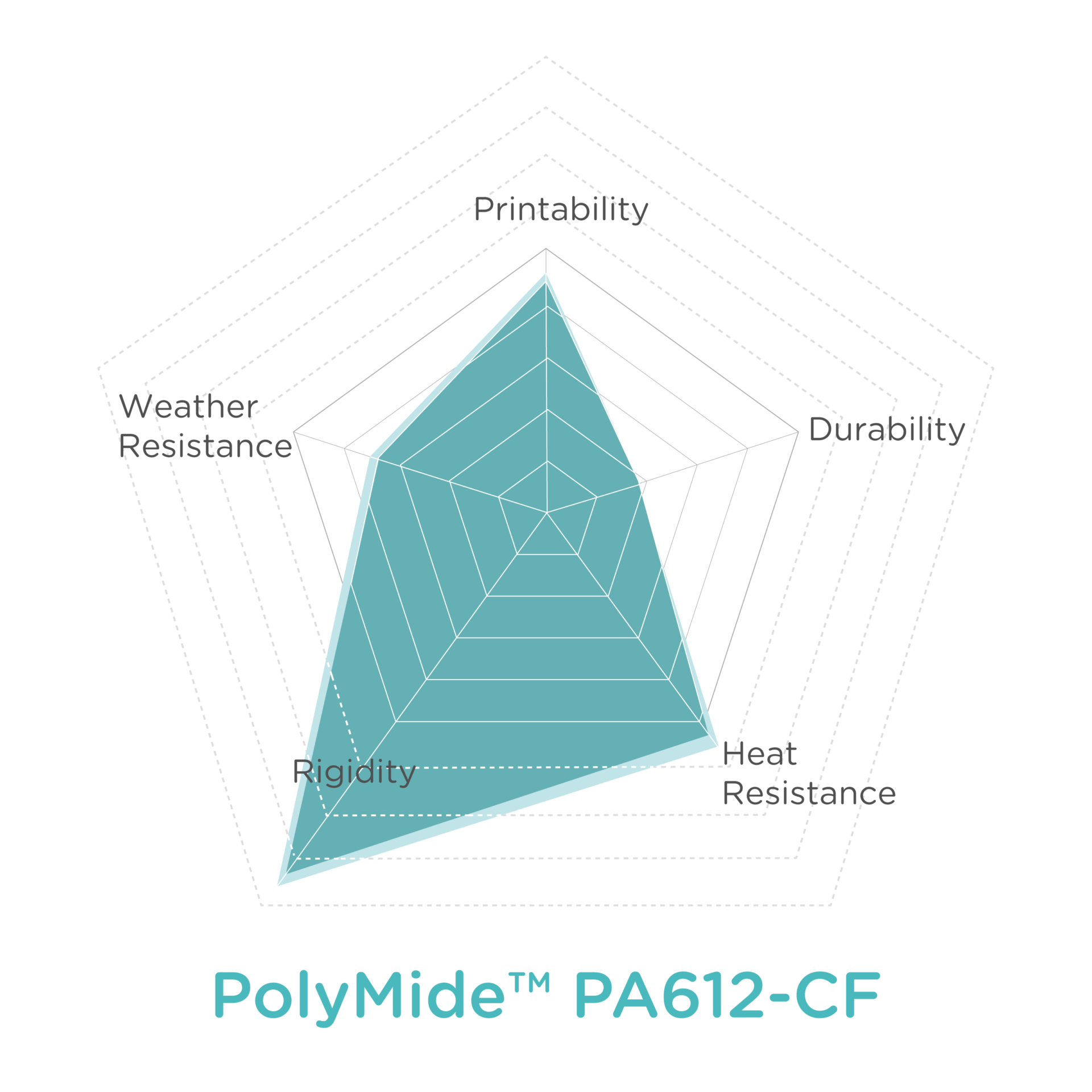

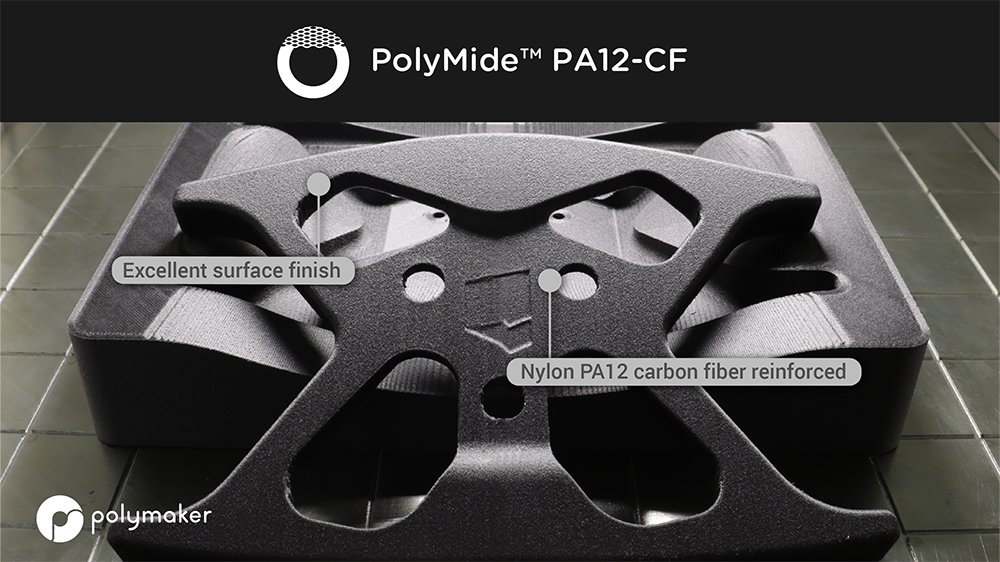

PolyMide™ PA12-CF is a brand-new engineering filament offering high stability in both printing and application, delivering predictable mechanical properties regardless of the operating environment. PolyMide™ PA12-CF achieves this through its base polymer, nylon 12, which displays greater moisture stability when compared to common nylon 6 filaments. This means that PolyMide™ PA12-CF printed parts display minimal change in mechanical properties from the dry state to the wet state, therefore, more predictable mechanical properties in final printed parts. PA12-CF features 10% chopped carbon fibers which add strength and stiffness while also lowering the coefficient of thermal expansion, these characteristics, paired with Polymaker’s Warp-Free™ and Fiber Adhesion™ technologies provide an easy to print filament with extremely desirable properties.

Fig.1 Steering Wheel Core and Mould

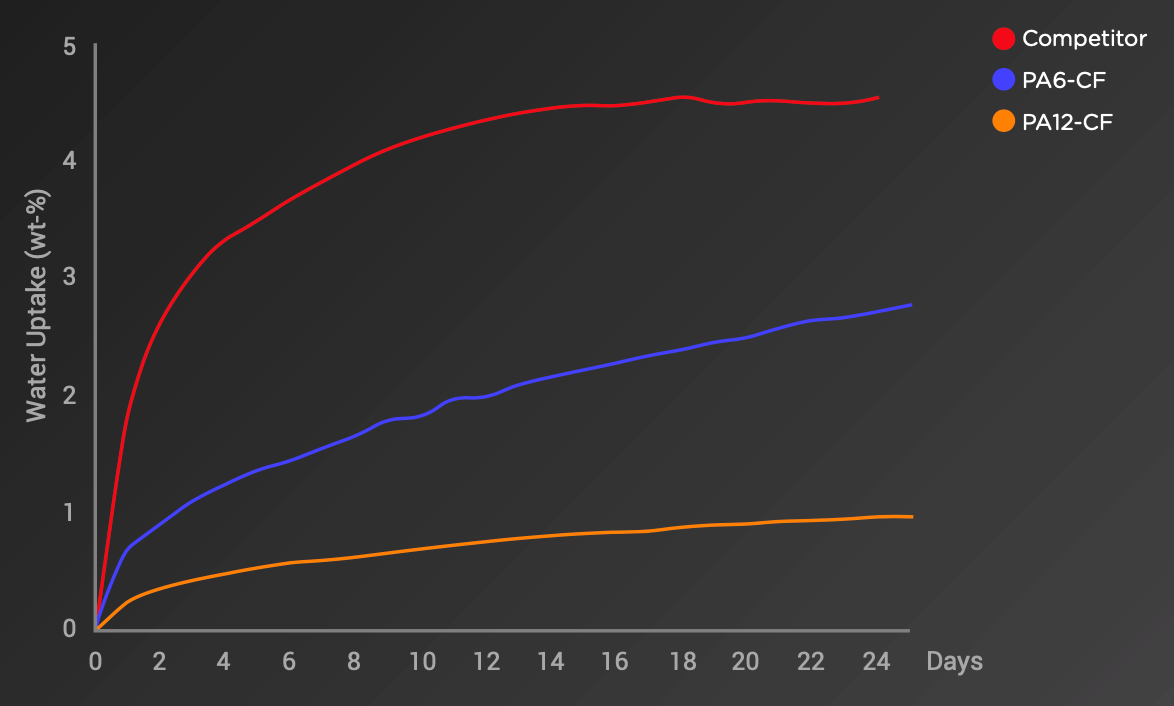

The main difference between PA12 and PA6 is moisture stability. The longer PA12 polymer chain is much more resistant to moisture absorption and will reach moisture equilibrium at a lower % than PA6 filaments. Less moisture absorption means that there is less change in mechanical properties from the dry state to the wet state.

Water molecules are attracted from the surrounding air to the polyamide matrix, forming a polar bond onto the polymer chain. This water molecule acts as a plasticizer inside the nylon and while it decreases tensile strength and stiffness, it increases toughness and impact resistance. Unless your 3D printed parts operate in particularly dry environments or are post processed with a moisture barrier, its generally assumed that all nylon printed parts will end up in their wet state properties in every-day use. In many applications the wet state characteristics are more desirable and its common on many nylon injection moulding lines to eject moulded parts straight into a bath of water to condition them to wet state properties before leaving the factory.

In 3D printing filaments must be dry, otherwise, any moisture which is inside the filament will boil inside the hot end and rupture out of the side of the extruded plastic, this greatly decreases the mechanical properties, surface finish, layer bonding and produces some other undesirable printing characteristics such as stringing and oozing. Once the part is printed however, the nylon will absorb moisture from the air naturally and reach an equilibrium inside the part. For PA12-CF, the moisture equilibrium is roughly 1.5% by weight with other brand nylon filaments absorbing up to 5% and over, this has a more drastic effect on the final properties of the part and a noticeable difference in the performance from dry to wet states.

Fig. 3 Moisture Absorption Curve

As PolyMide™ PA12-CF displays a smaller shift in characteristics from dry to wet states it therefore delivers more predictable results in real-world applications. This allows you to design more accurately according to stress models and design loads, allowing you to further optimize your 3D printed parts.

Furthermore, the printability of the filament is also increased as the handling, storing, and printing of the material benefit from less moisture absorption. The filament is still hygroscopic, and we advise storing and printing PolyMide™ PA12-CF from inside the PolyBox™.

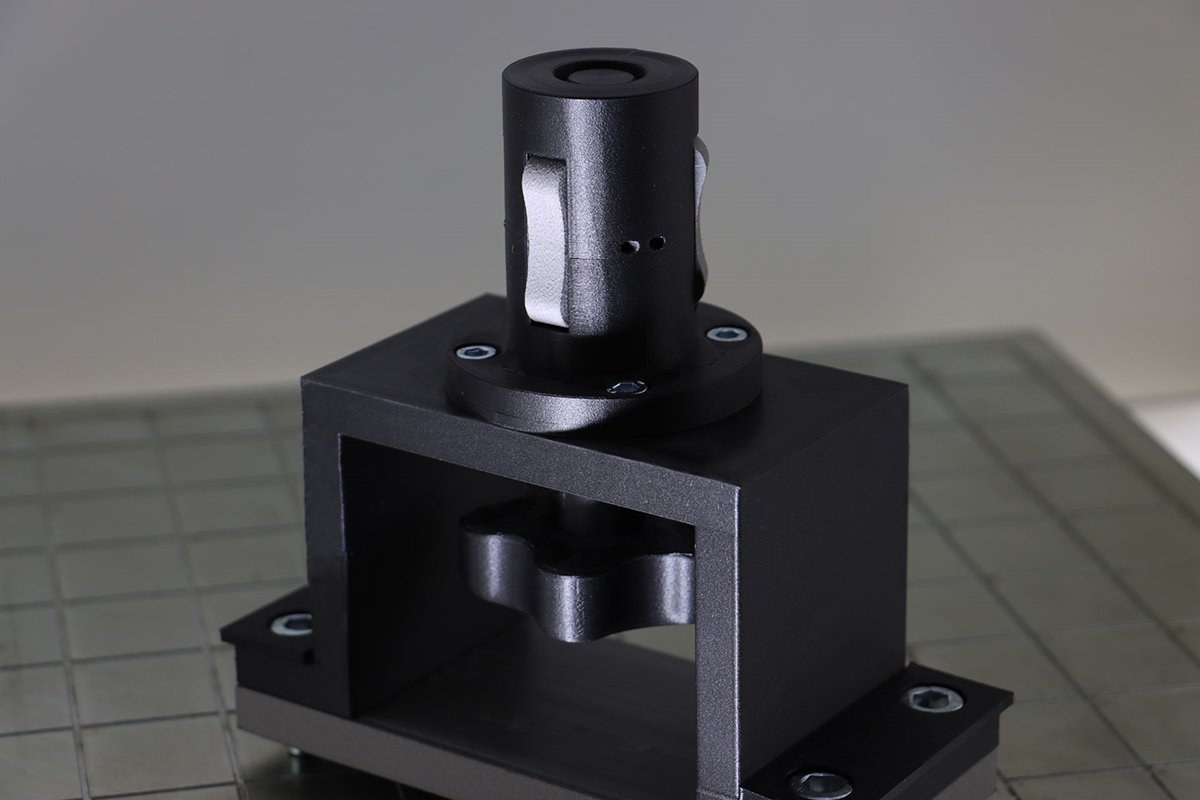

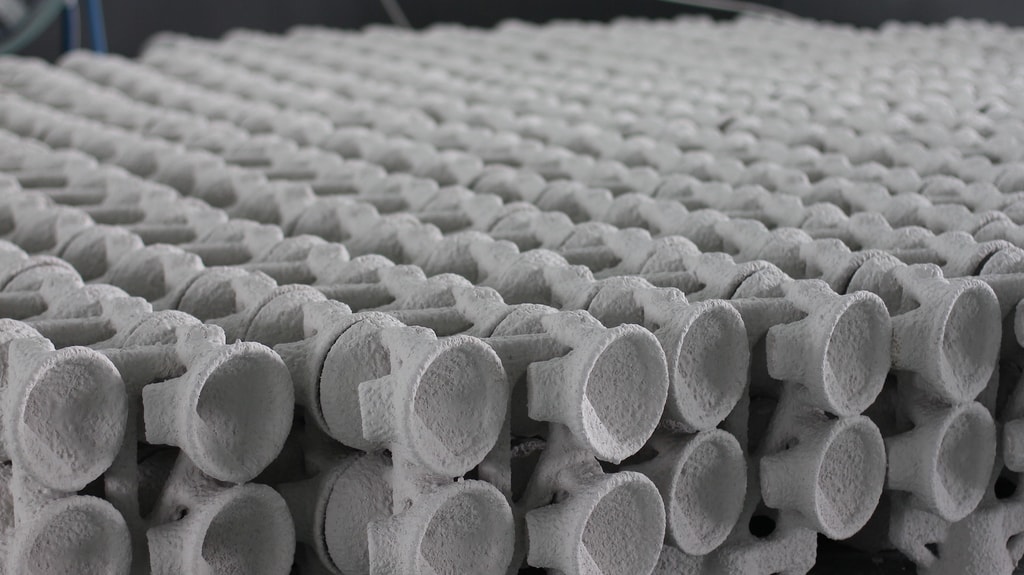

Fig. 4 Pipe Assembly Tool

Our material scientists have employed two Polymaker technologies into PolyMide™ PA12-CF. Warp-Free™ Technology, ensures no warping during printing, which is achieved by controlling the crystallisation behaviour of the polymer chains. Fiber-Adhesion™ Technology optimises the surface chemistry of the carbon fibers so they bond homogenously within the polymer matrix. This provides a greater strength on the z-axis when compared to competitor filaments whilst also offering easier printing on a multitude of 3D printers, desktop and industrial.

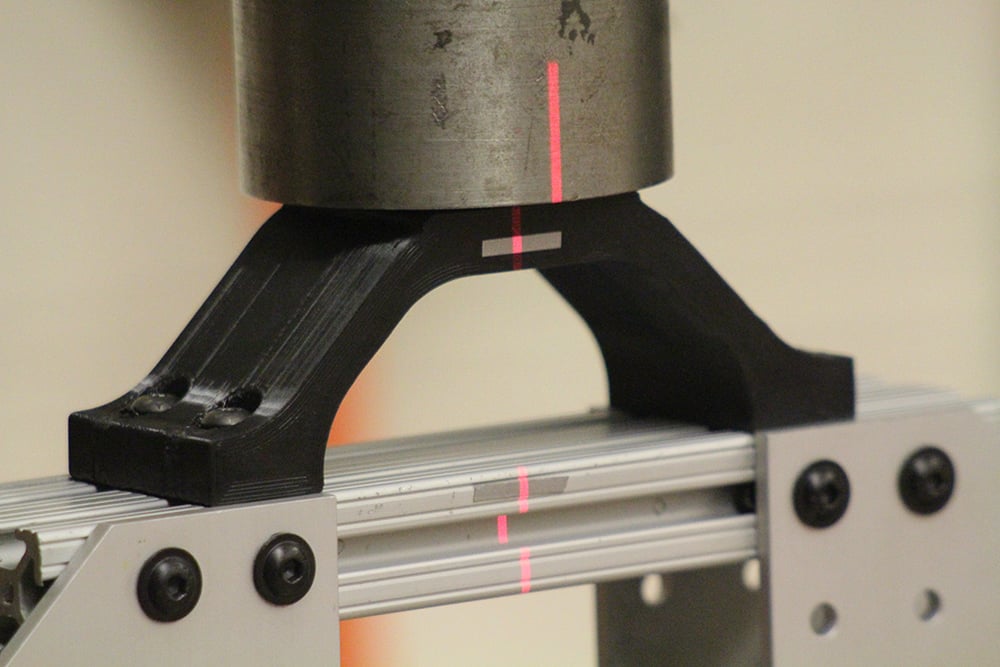

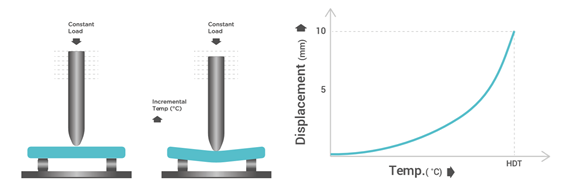

PolyMide™ PA12-CF features a heat deflection temperature of 131°C lending itself to operate in demanding environments where heat and stress are critical design factors. Paired with superior tensile strength and stiffness compared to other extrusion-based filaments, PolyMide™ PA12-CF is an engineering plastic that can outperform many other extrusion-based materials where strength to weight ratios are critical.