September 30, 2021

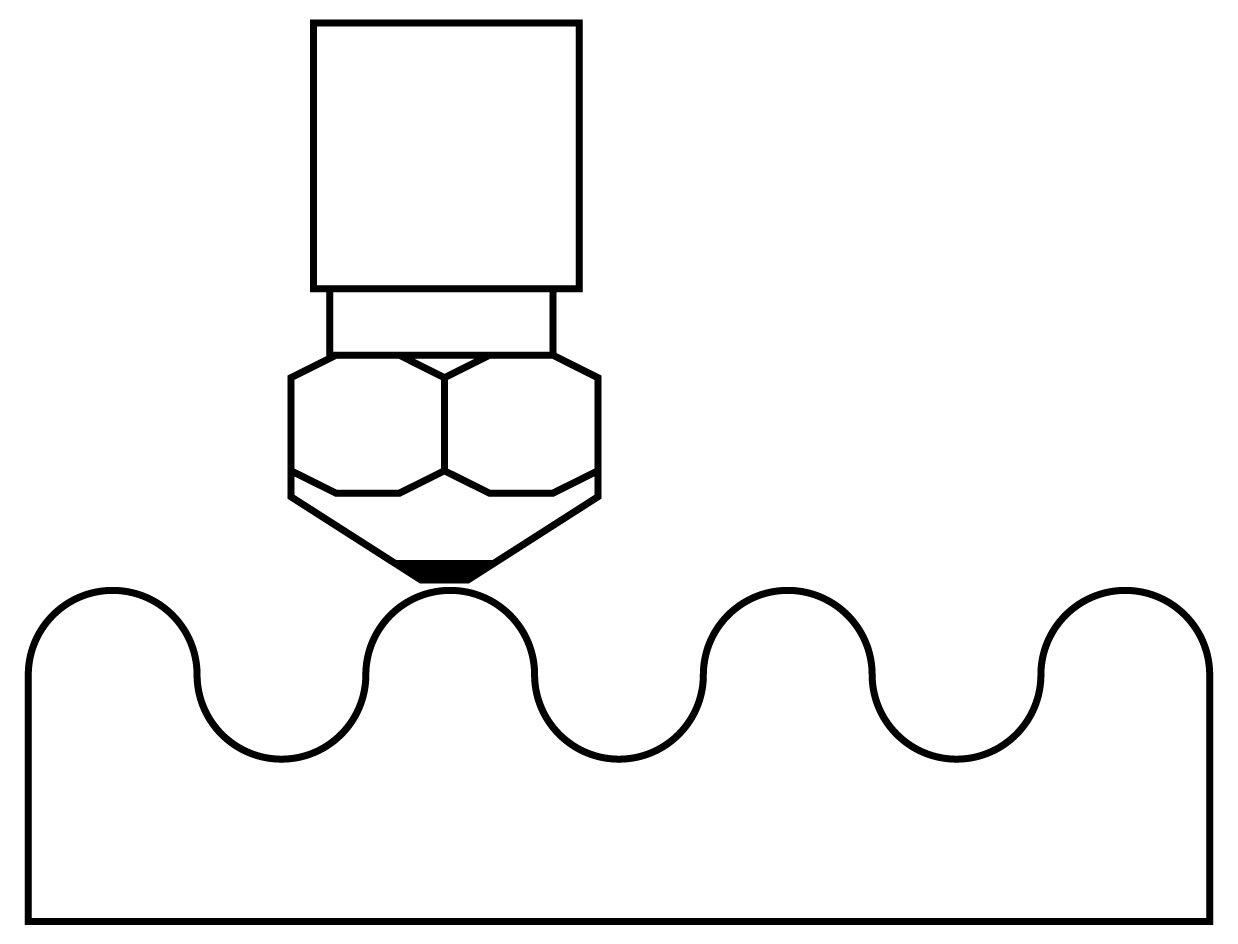

PolyCore™ ASA-3012 is reinforced with 20% glass fiber, featured with excellent weather resistance and UV stability as well as strong mechanical properties. ASA-3012 is known for its ability to withstand harsh outdoor environments, making it a popular choice for outdoor applications such as bridge, horticulture and landscape.

PolyCore™ PETG-1013 is a glass fiber reinforced (30% mass percent) PETG pellets featuring excellent dimensional stability, strong mechanical properties and weather resistance. Designed for Big Area Additive manufacturing (BAAM) technology, PETG-1013 can withstand impact and stress well, which makes it an ideal material for printing objects that will be subjected to wear and tear or rough handling.

PolyCore™ PETG-1000 is cost-effective PETG pellet with good printability and unique aesthetic effect, specially designed for Medium Area Additive Manufacturing (MAAM) and Big Area Additive manufacturing (BAAM) technology. It is suitable for indoor applications such as furniture, luminaires and decoration.

PolyCore™ ABS-5012 is 20% glass fiber reinforced ABS pellet featured with great cost effectiveness, excellent printability, balanced mechanical properties and broad applicability. This product can be applied to a wide range of scenarios including but not limited to: low-to-mid temperature tooling, architecture template such as concrete mold, general prototyping, etc.

PolyCore™ ABS-5022 is 20% carbon fiber reinforced ABS pellet with strong mechanical properties, great dimensional stability, good durability and high thermal conductivity with relatively low CTE. It is suitable for applications where durability & thermal resistance matters, for example, marine prototype and low-to-middle temperature composite tooling ( <80℃).

Composite tooling used in autoclave is one of the most important applications in BAAM. PolyCore™ PC-7414 is designed for medium temperature autoclaving tools, which can withstand up to 140 oC during curing process. This grade is still under development and is on our releasing schedule.

Please fill in the form below or if you have other questions are not included in the form, please contact us through [email protected]. We will get back to you soon.

Please fill in the form below or if you have other questions are not included in the form, please contact us through [email protected]. We will get back to you soon.