What is a TDS?

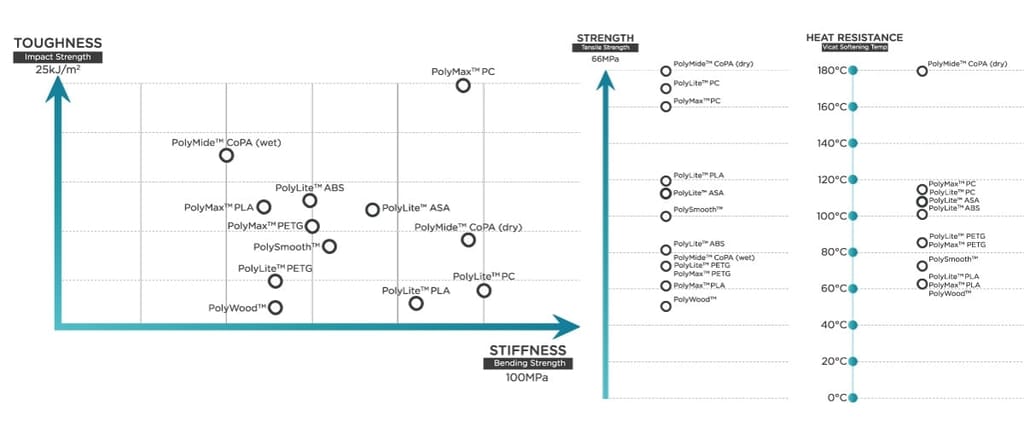

a Technical Data Sheet (TDS) summarizes the performance and technical properties of a 3D printing material delivered through a series of standardized tests. This allows users to choose certain characteristics specific to their application when choosing the right 3D printing material. With the advancement of Polymaker’s industrial range, the TDS plays an integral role in highlighting each product’s varying characteristics and additionally, supplies the end-user with the basic print settings and tips to begin developing print profiles.

All TDS tests are conducted with 3D printed specimens in the X-Y and Z axis and depending on the characteristics of the material, specific tests and environments are used. This provides our end-users with the most accurate and appropriate information for their 3D printing application.

Why does Polymaker introduce a new version TDS?

Polymaker's products are increasingly being used in professional and demanding applications. Knowing what to expect from a material is critical to a parts performance and can aid in the behavioral analysis and curation of 3D printed parts in end use applications. We want to build on the information already found in our TDS and provide more in-depth technical parameters for our customers.

What’s new?

- Moisture Absorption Curve

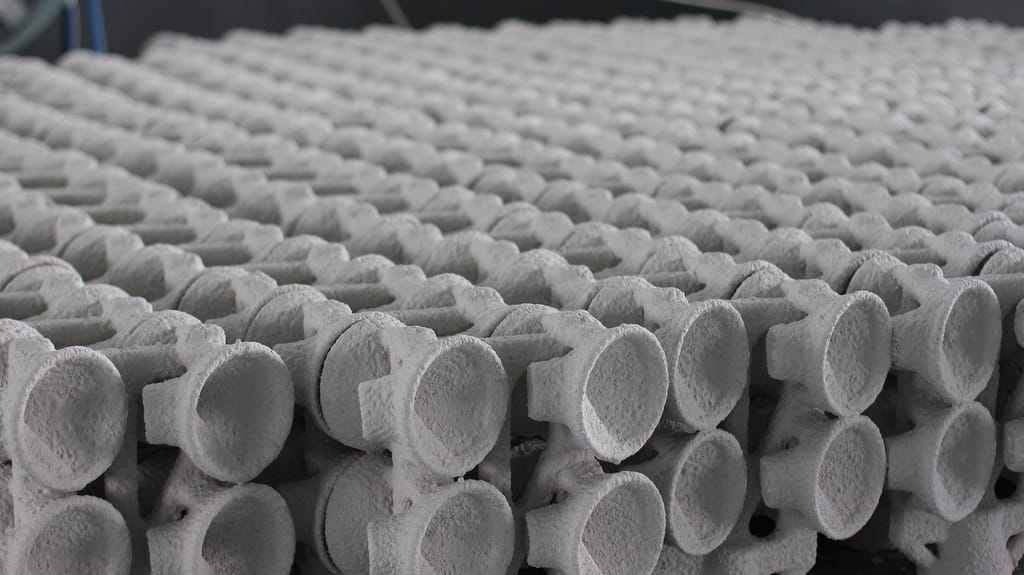

The moisture absorption curve is determined by the nature of the material itself with some materials more susceptible to moisture ingress than others. The problem of moisture absorption will not only affect the 3D printing process, but also is affecting the properties of a 3D printed part after printing.

If a filament has absorbed moisture, when reaching a heated nozzle, the moisture heats up and rapidly expands rupturing the filament, causing bubbles and inconsistent extrusion. This can significantly reduce mechanical properties and layer adhesion causing print defects such as oozing, stringing and poor surface quality.

In order to solve this problem, Polymaker completely dries all products before vacuum sealing them in an aluminum foil bag with a desiccant. Polymaker also offers the PolyBox™ as a storage solution for all filaments during storage and printing.

To help users to understand how filaments absorb moisture, Polymaker has added the Moisture Absorption Curve into the new version TDS.

In the Moisture Absorption Cure, you can learn how a filament absorbs moisture under the standardized testing condition of 70% relative humidity at 23℃。

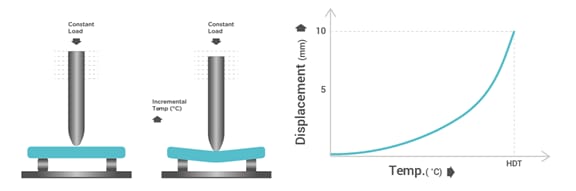

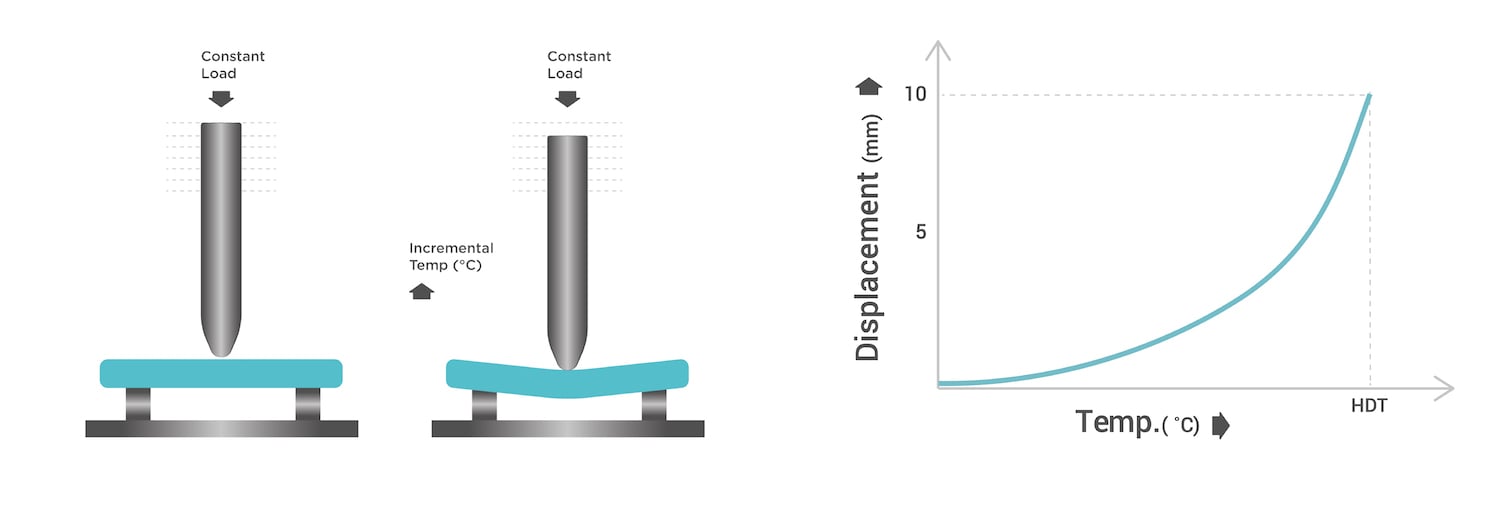

- Heat Deflection Temperature (HDT) Curve

There are different ways to illustrate the concept of “Heat Resistance”. Polymaker used to provide glass transition temperature, melting temperature, crystallization temperature, decomposition temperature, and Vicat softening temperature in the TDS. Now Polymaker has added heat deflection temperature (HDT) to further the understanding of heat resistance in a 3D printed part.

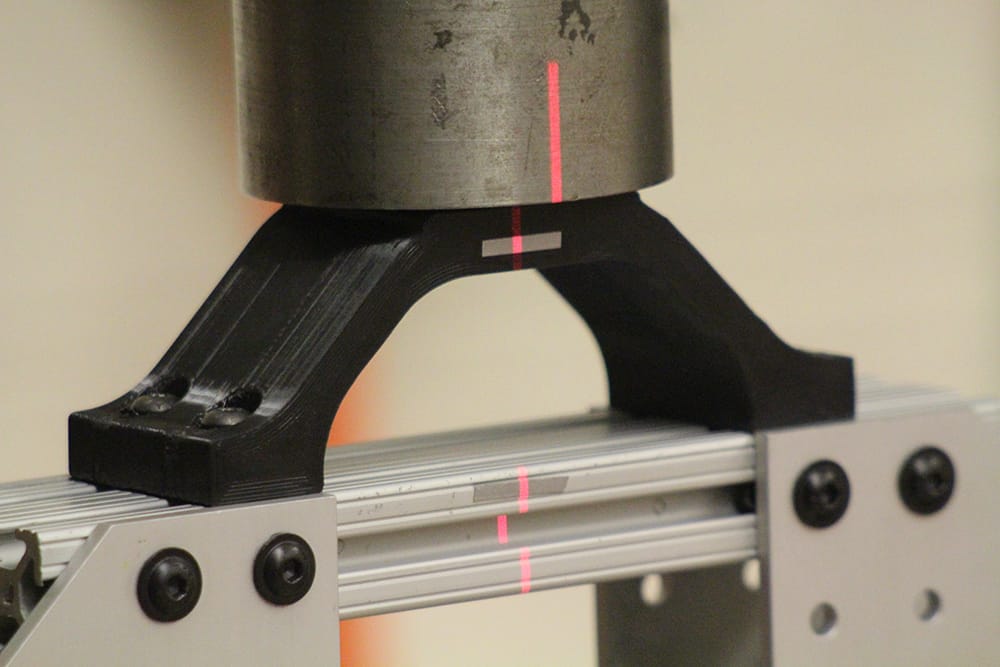

The heat deflection temperature is the measure of the temperature at which a polymer undergoes a certain amount of deformation under a constant load. The test is conducted by placing a 3D printed specimen under a constant load, while steadily increasing the temperature by 2 °C/min. The displacement is measured over a range of 10mm and plotted to create the HDT curve.

The heat deflection temperature is determined by the following test procedure outlined in ISO 75. The test specimen is loaded in three-point bending rig in the edgewise direction. The outer fiber stress used for testing is either 0.455 MPa or 1.82 MPa, and the temperature is increased at 2 °C/min until the specimen deflects 0.34 mm. This is similar to the test procedure defined in the ISO 75 standard.

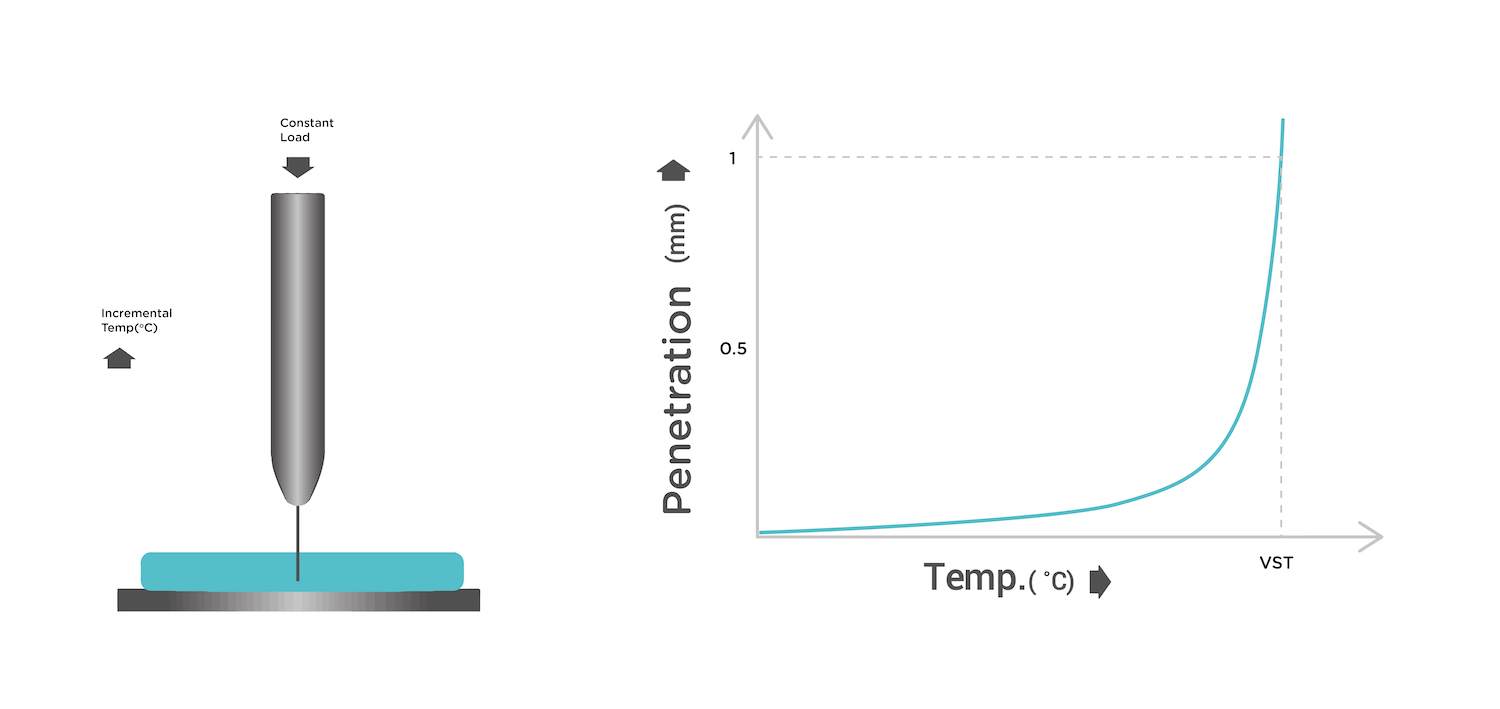

Whilst comparable to HDT, the Vicat softening temperature differs by providing a testing method that simulates the point at which temperature softens the material’s physical properties enough for an external object under a set pressure to penetrate the outside surface of the specimen by 1mm.

What else?

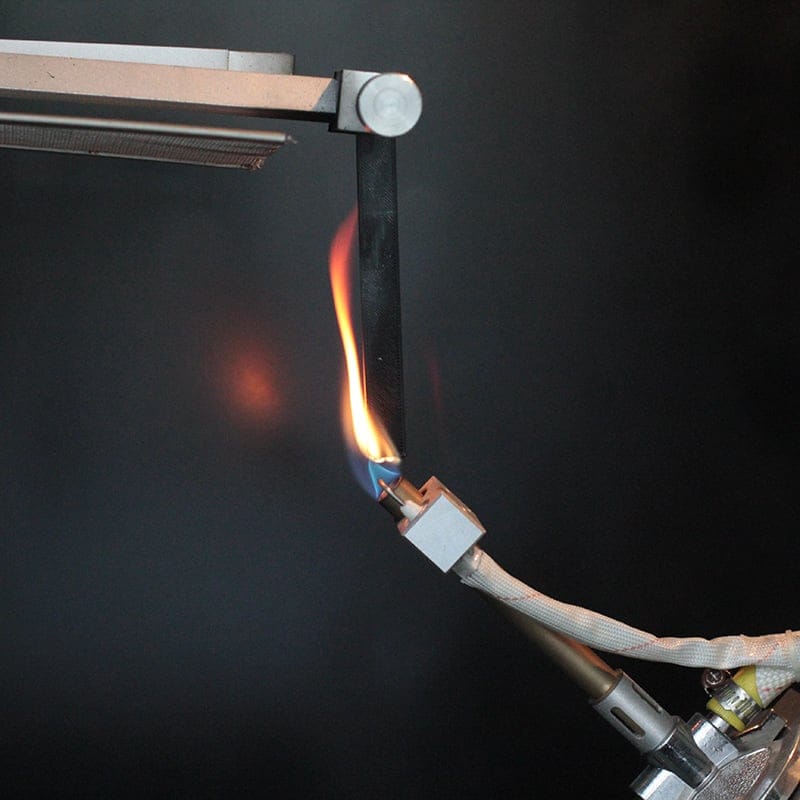

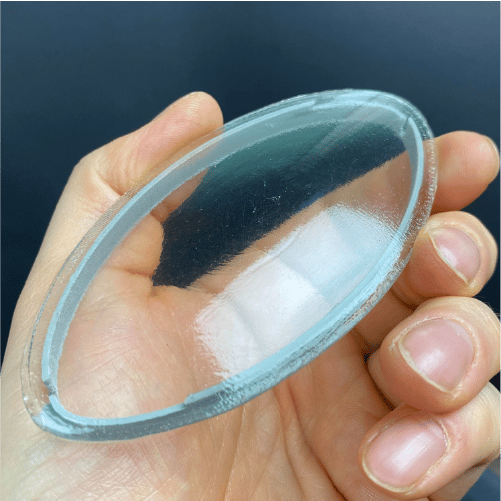

Aside from Moisture Absorption Curve and Heat Deflection Temperature (HDT) Curve, Polymaker will also add light transmission, flame retardancy, chemical resistance, thermal conductivity, and heat shrinkage rage into future versions of the TDS.

Where to find the new version TDS?

You can find the new version TDS from the DOWNLOAD section of Polymaker website.