With the industrial-grade 3D printing technology gradually challenging traditional manufacturing processes such as machining and injection molding, additive manufacturing has expanded from prototype production to more critical applications in end products.

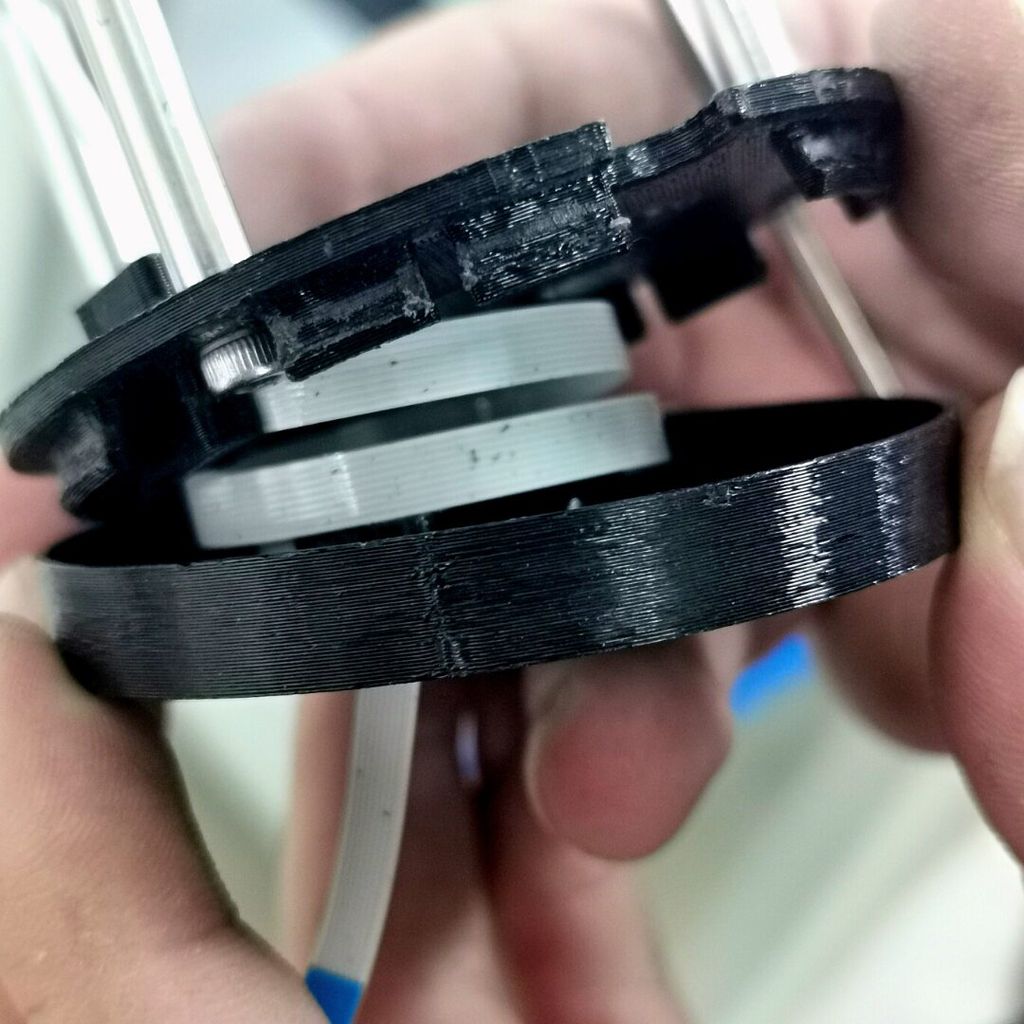

Recently, a motion control company that provides high-precision direct-drive motors was designing suitable connectors for FFC (Flexible Flat Cable) in their research and development equipment. FFC are commonly used connection structures in electronic devices, and the company needed to place them in customized connectors to connect rotary motors and optoelectronic switch devices.

Initially, the company approached an aluminum processor for a quote, but the response forced them to seek alternative solutions:

- MOQ (Minimum order quantity) limitation: 50 pieces per item

- Processing limitations: Some slot designs were too complex for traditional machining processes

- Unstable lead time: A two-week lead time with no guarantee of transportation time.

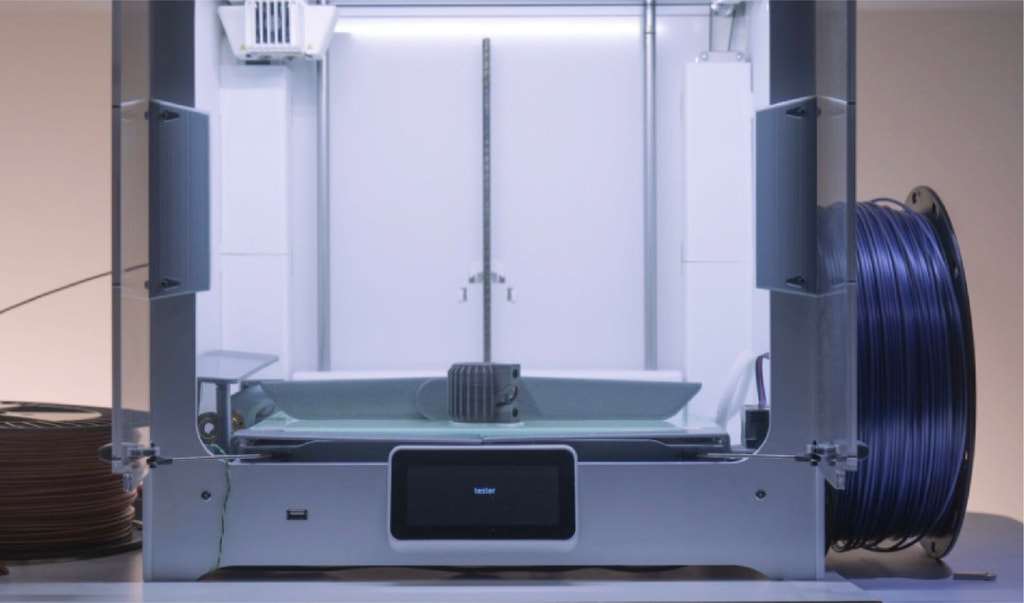

Compared to aluminum machining, 3D printing technology not only offers faster production speed but also enables lighter part weights. Additionally, 3D printing allows for the simultaneous production of parts with different specifications, achieving customized requirements more economically and efficiently. In the end, the company decided to collaborate with Amesos mfg and Polymaker to produce connectors for FFC.

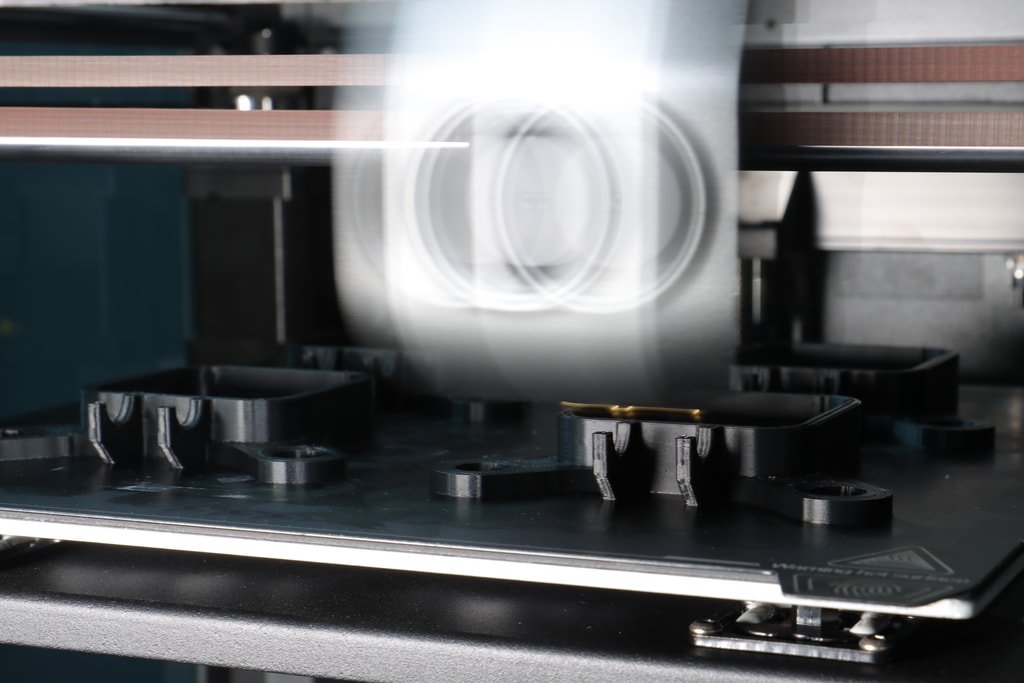

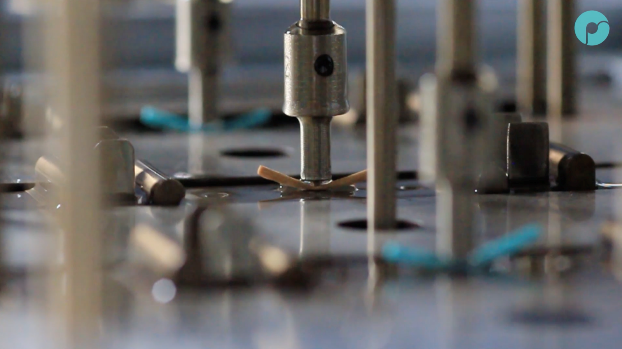

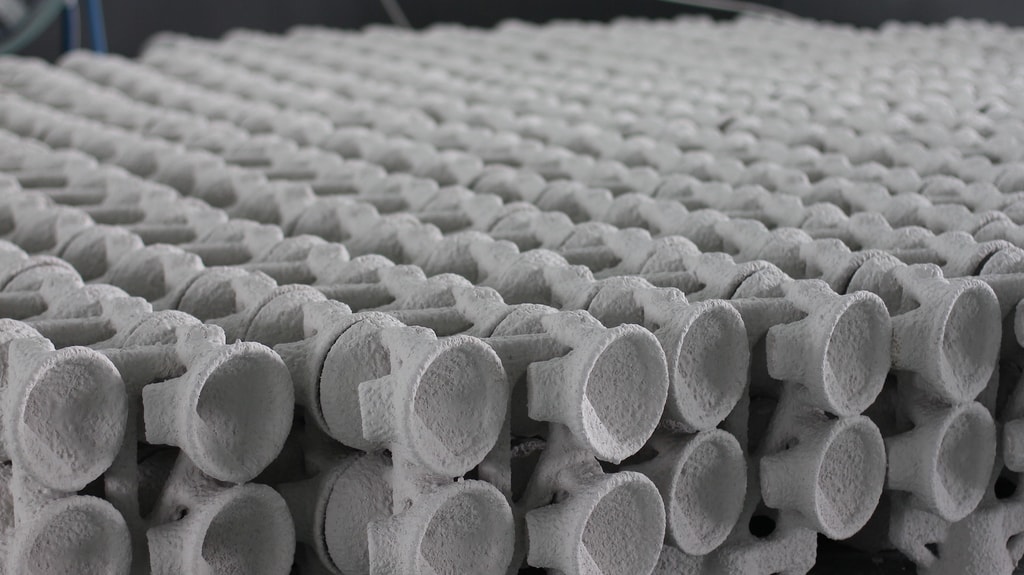

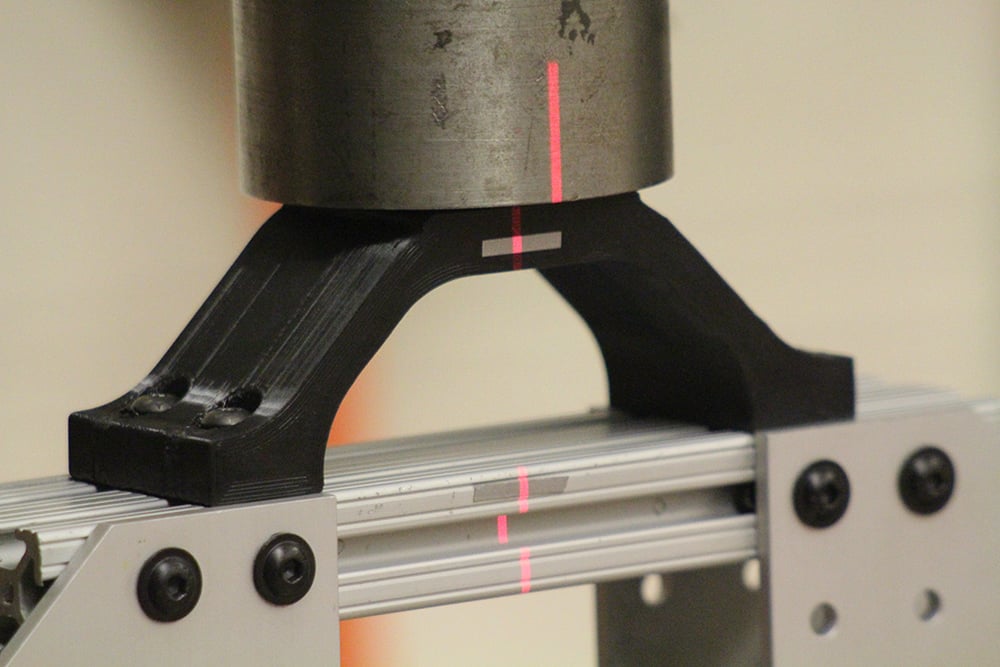

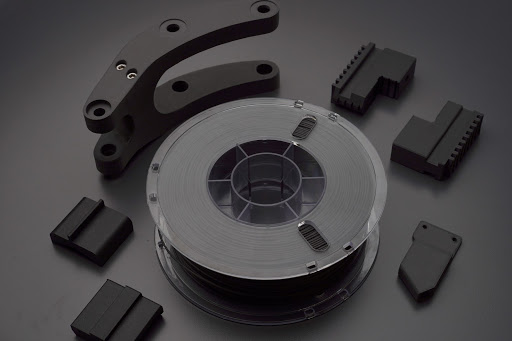

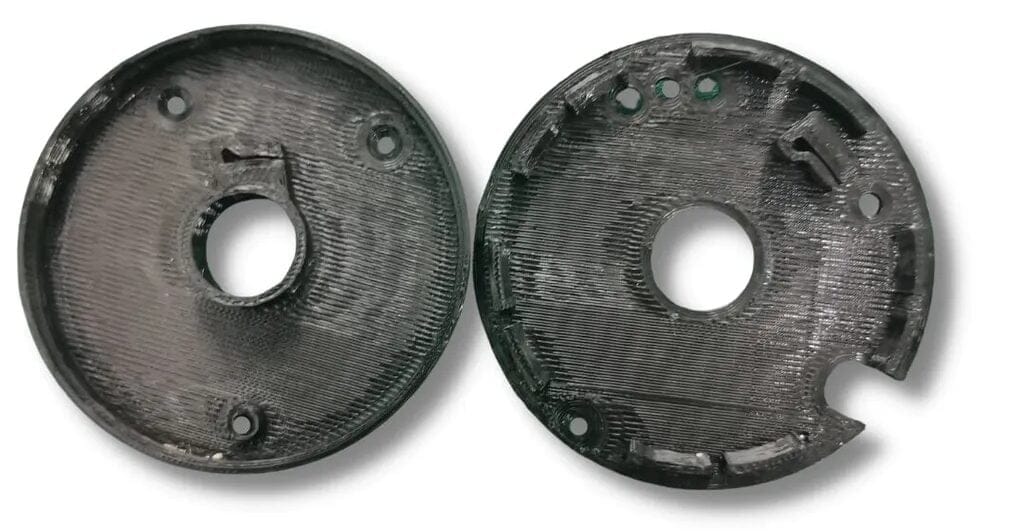

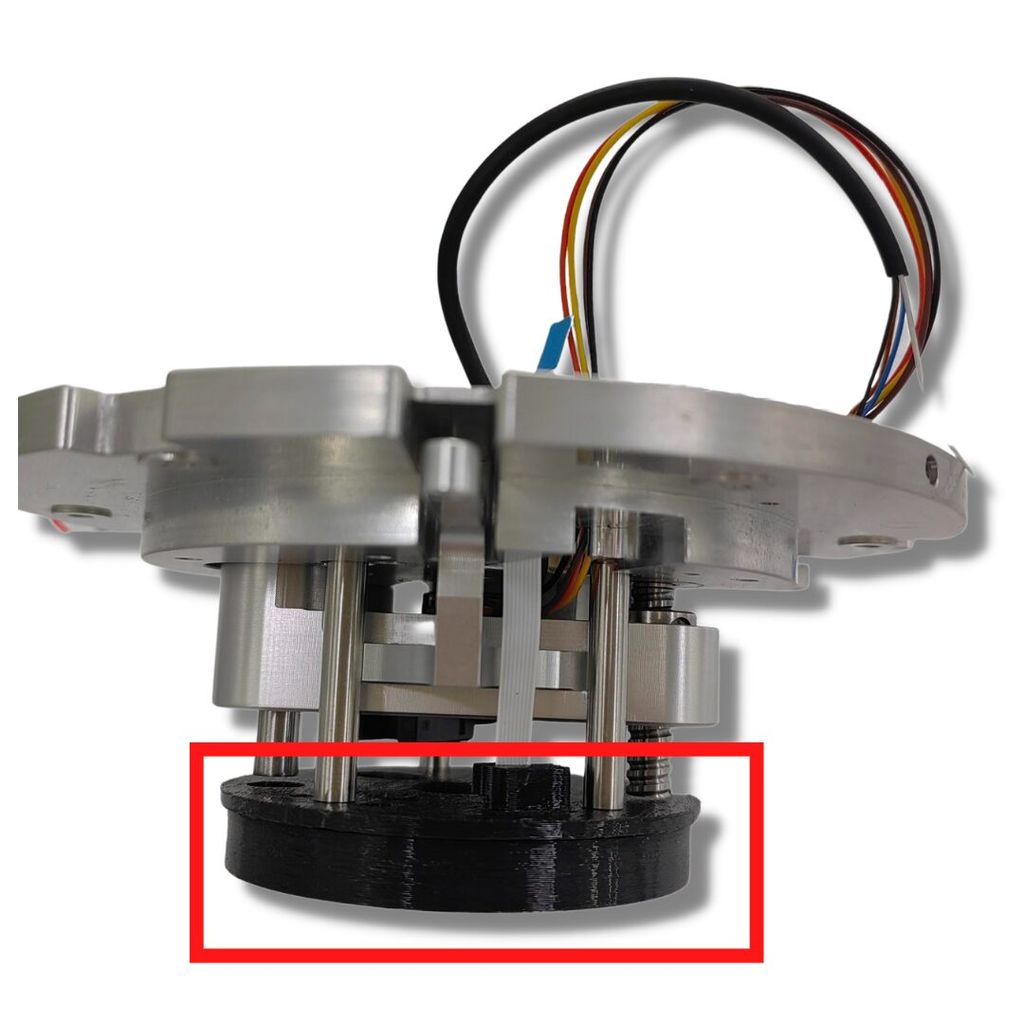

In this collaboration, the customized connector features multiple holes and slots in its internal design, serving the purpose of later assembly and positioning. The connector is designed in two parts, and once assembled, it can securely hold the FFC inside, with its ends connected to the rotary motor and other electrical components.

The rotary motor drives the continuous rotation of the FFC, while the connector allows for separation and rotation. The design also includes limiting slots to prevent the cable from tangling or breaking. After the parts are printed on the same day, the customer can immediately proceed with the trial installation.

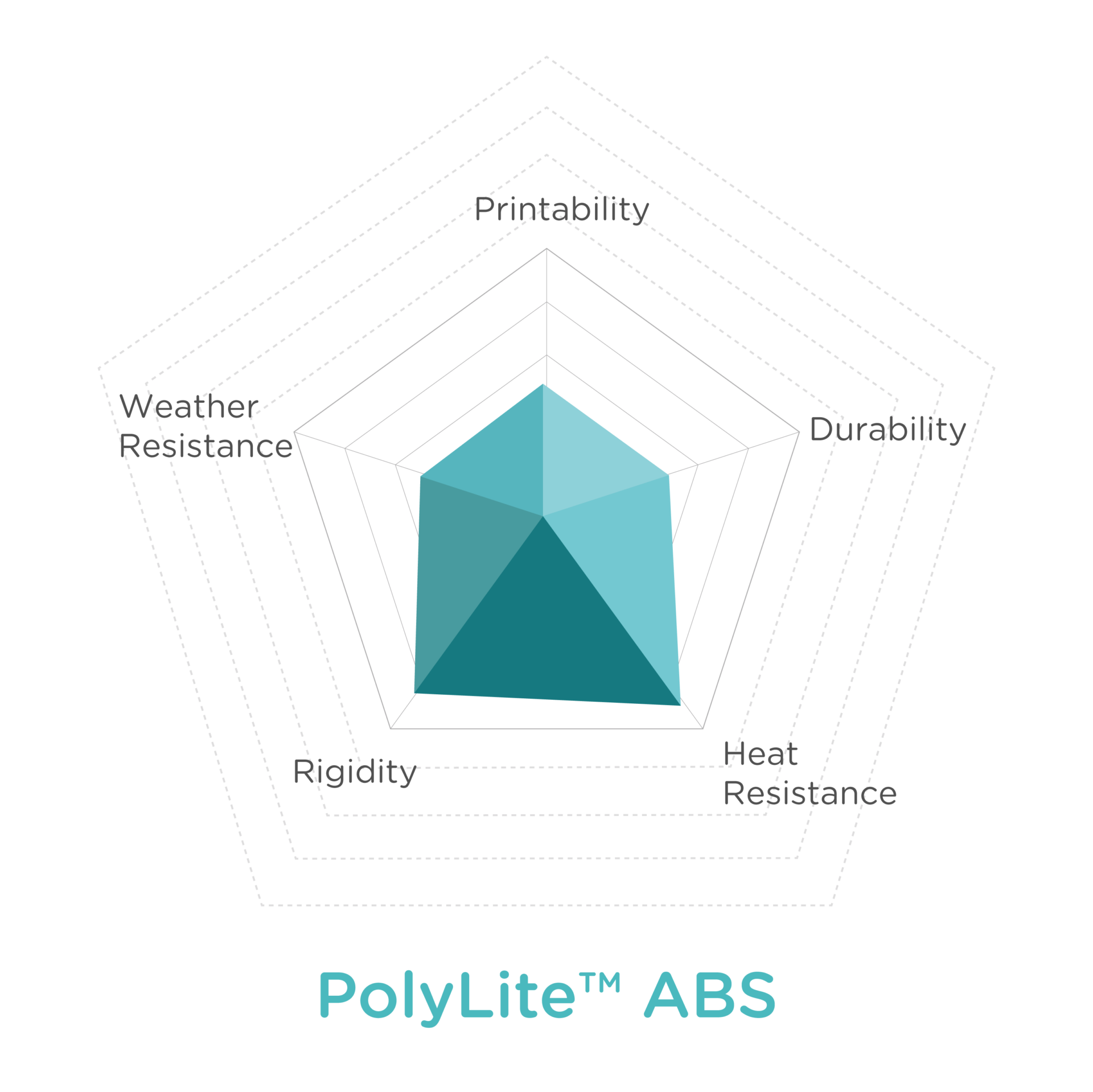

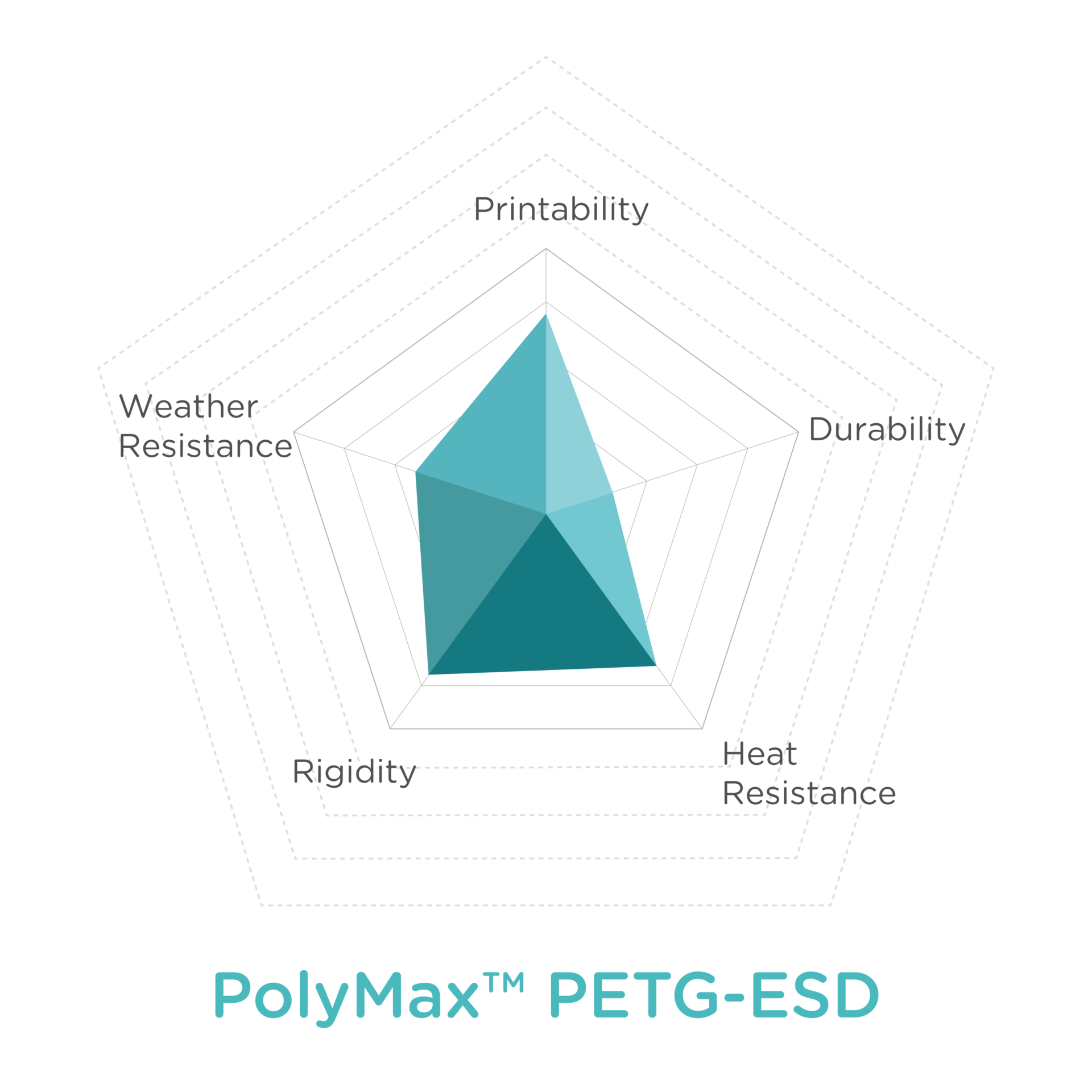

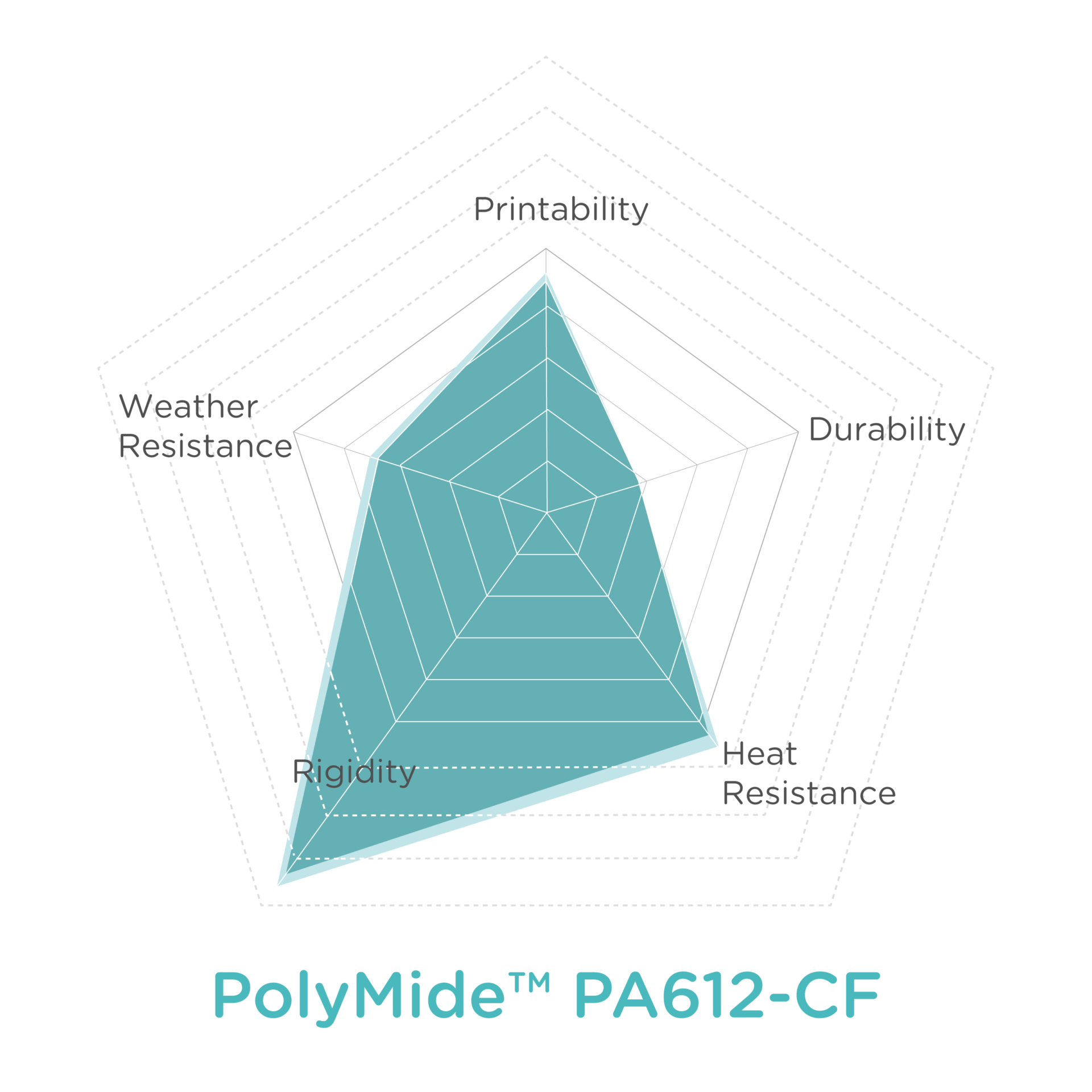

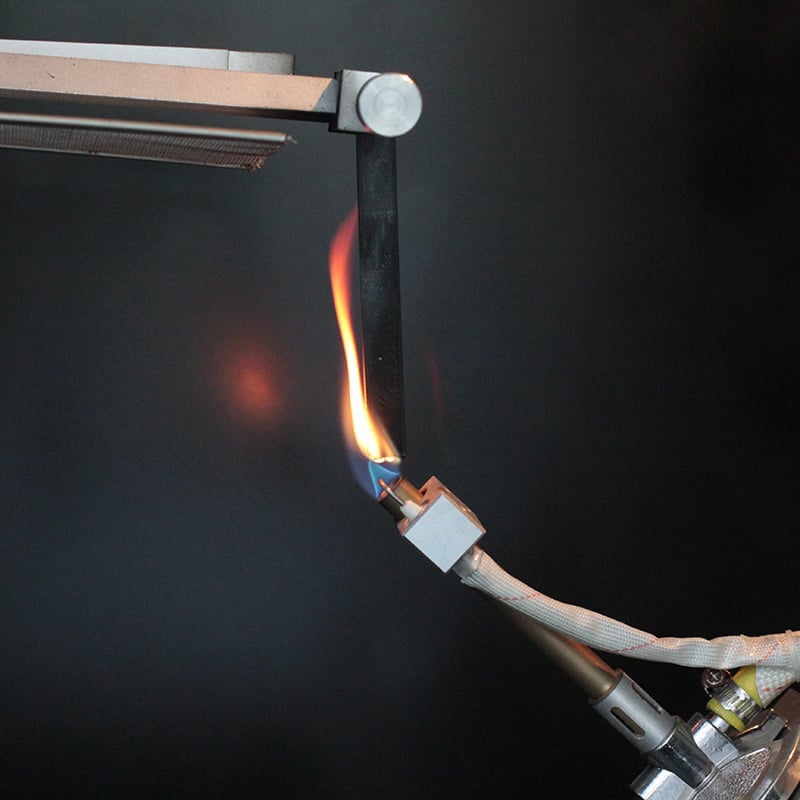

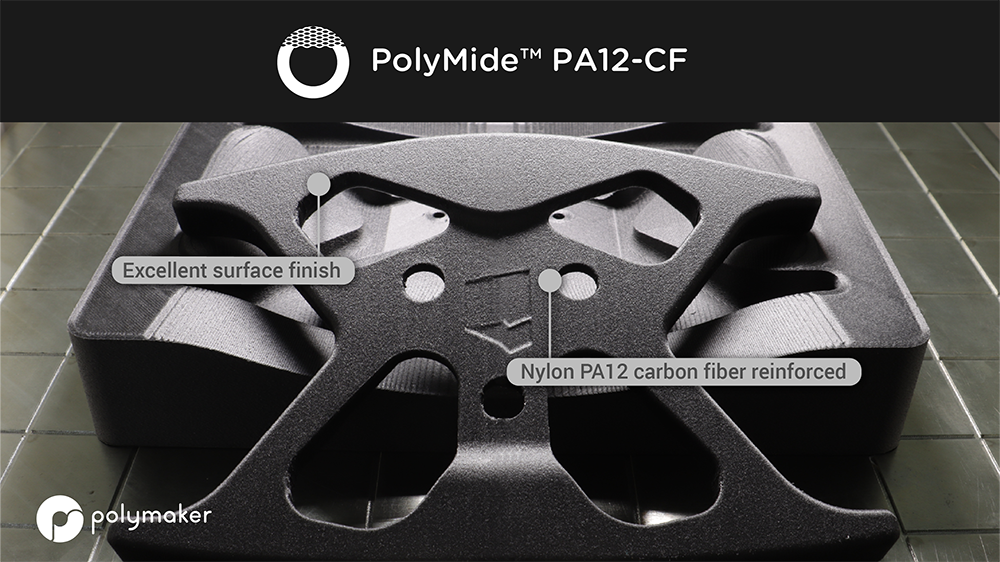

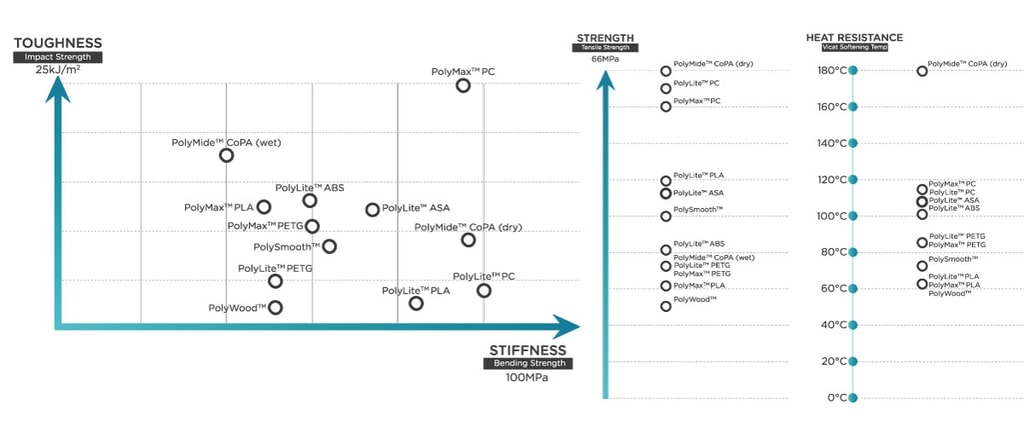

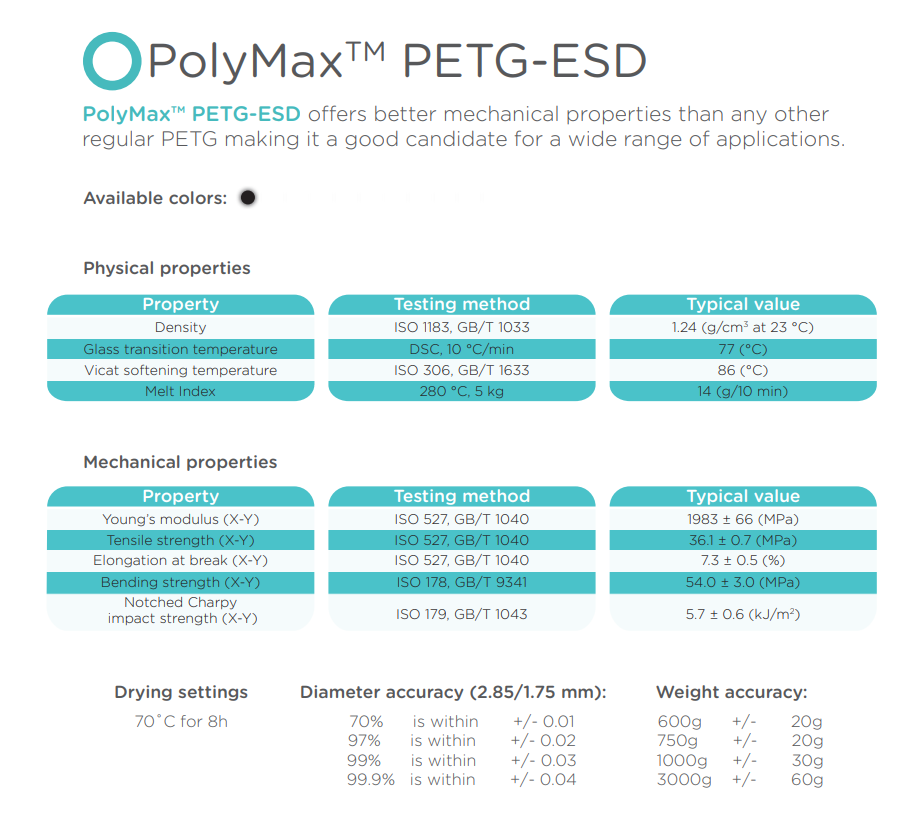

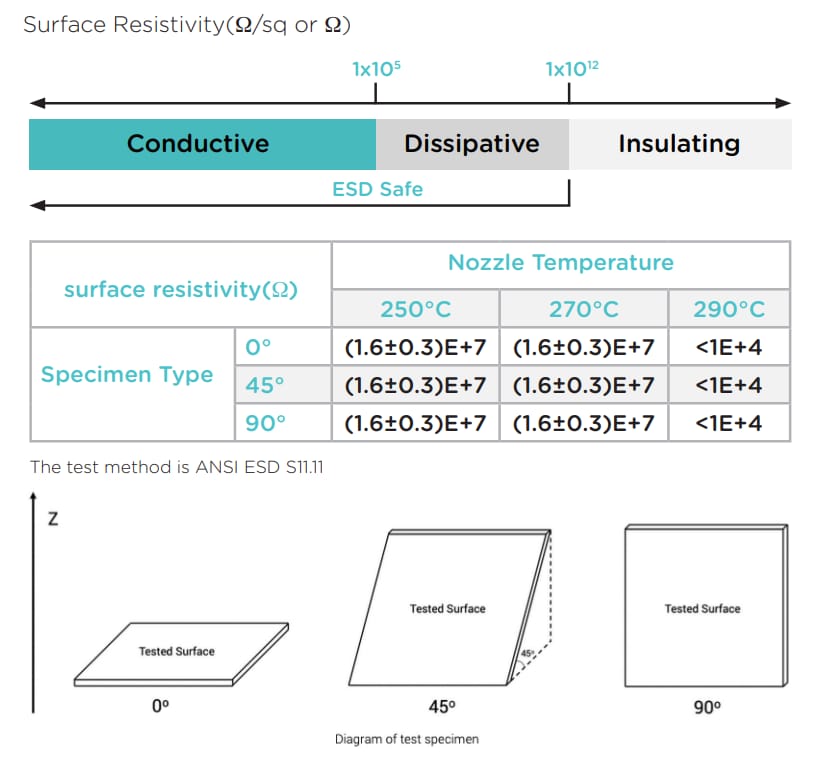

Considering that the FFC ribbon cable will experience continuous friction as it rotates with the rotary motor, the material choice for the connector must be wear-resistant while providing protective properties. In addition, the electronic components require ESD-safe characteristics. PolyMax™ PETG ESD from Polymaker becomes the ideal choice for the material used in producing these parts.

PolyMax™ PETG ESD not only offers higher strength, impact resistance, and temperature resistance compared to PLA but is also easy to print. Its ESD-safe properties make it suitable for a wide range of applications in the electronics industry, including tooling fixtures, functional prototype design, and electrical enclosure manufacturing.

Through the collaboration between Polymaker and Amesos, the customized production reduced the costs by 85% compared to aluminum machining, and the printed parts were delivered and installed within three days. This signifies that additive manufacturing:

- Enables small-batch customization, reducing production lead times by months and significantly lowering indirect costs.

- Breaks design limitations imposed by traditional processes, allowing customized parts and complex designs to be produced in a more cost-effective and efficient manner.

- Helps customers respond to market demands more quickly without the need for excessive equipment costs or expensive tooling investments, enabling operational diversification.

- Facilitates digital production, overcoming supply chain disruptions and eliminating unnecessary inventory.