Polycarbonate (PC) materials specifically designed for industrial 3D printers with a heated chamber

New materials bring strong mechanical and thermal properties to METHOD X 3D printer for a wide range of engineering applications.

BROOKLYN, N.Y., Sept. 17, 2020 – MakerBot, a global leader in 3D printing and subsidiary of Stratasys Ltd. (Nasdaq: SSYS), today announces that Polymaker, a leading provider of 3D printing materials, has qualified three polycarbonate materials for MakerBot LABS™ for the MakerBot METHOD X™ 3D printer.

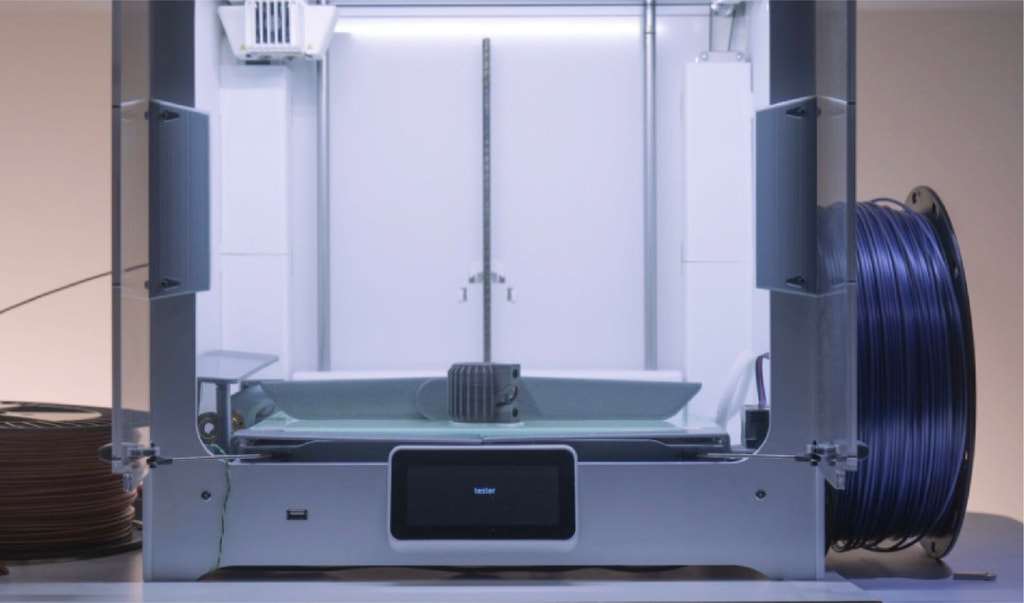

Polymaker™ PC-PBT, PolyMax™ PC-FR, and PolyLite™ PC are available to print on the METHOD X 3D printer with the MakerBot LABS Experimental Extruder. This extruder turns METHOD into an open materials platform, enabling users to print with a wide variety of third-party materials on an industrial 3D printing platform. The latest material additions from Polymaker to the LABS portfolio aim to enable METHOD X users to harness the strong mechanical and thermal properties of polycarbonate (PC), while reducing problems such as warping and curling that typically occur when used with conventional desktop 3D printing machines.

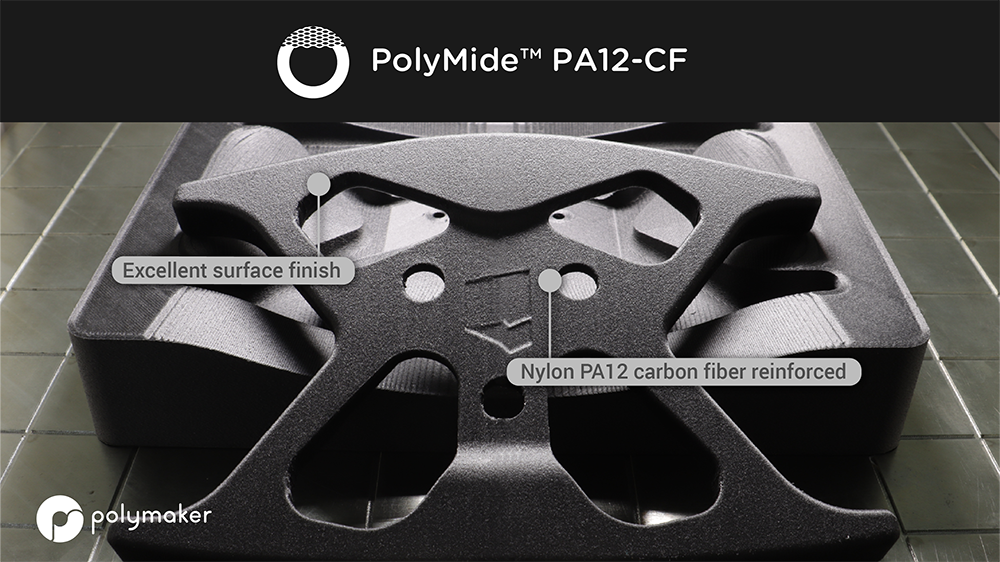

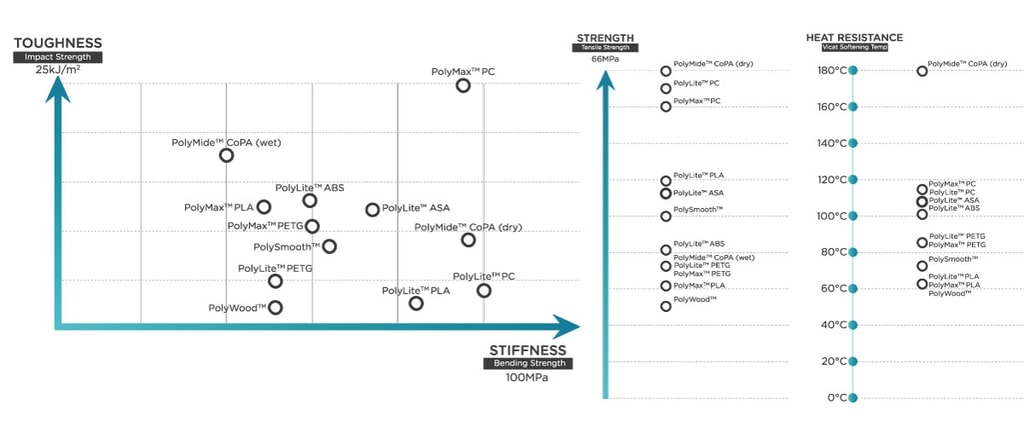

Polycarbonate is a popular high-performance engineering material that possesses a unique balance of toughness, good light transmission, high heat resistance, and excellent electrical resistance. It is lightweight, has the ability to transmit light as effectively as glass, and withstand impacts better than other thermoplastics such as ABS. Due to these properties, PC materials are commonly used for functional prototyping and end-use parts in the production of automotive components, protective gear, medical device components, and exterior lighting fixtures.

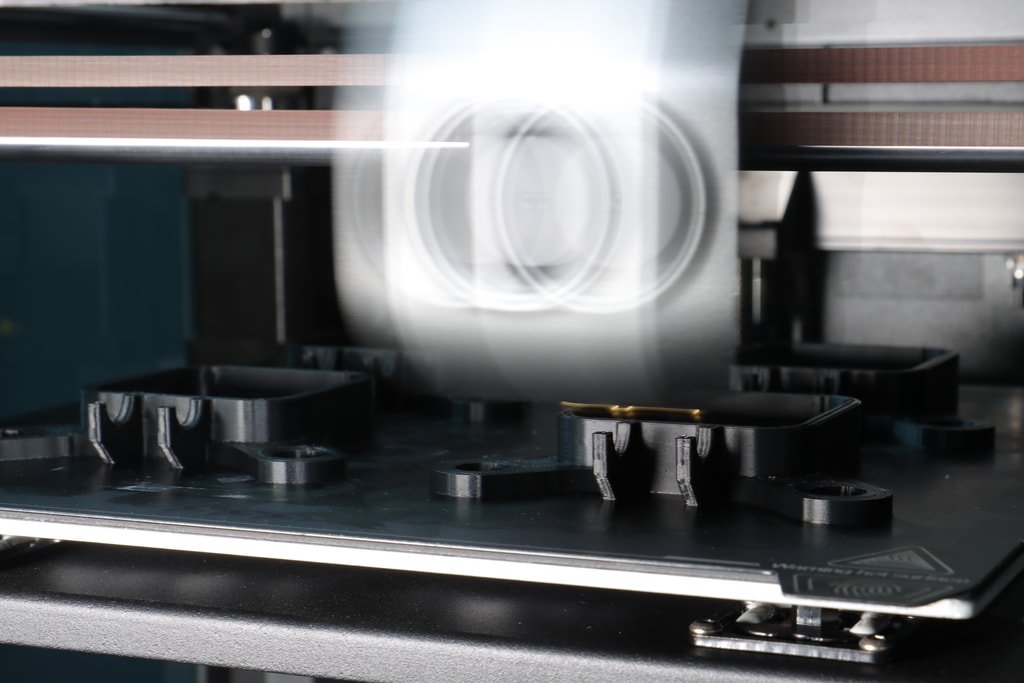

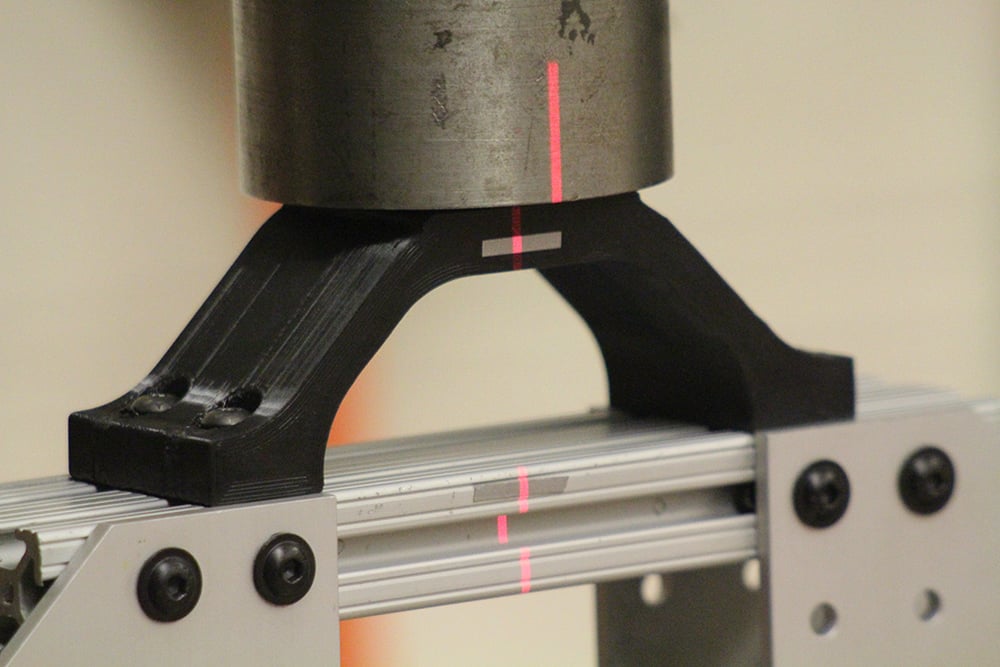

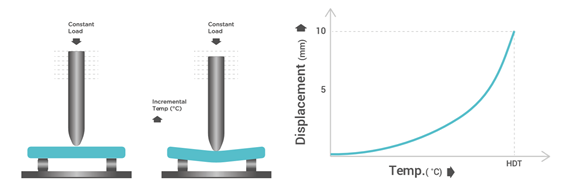

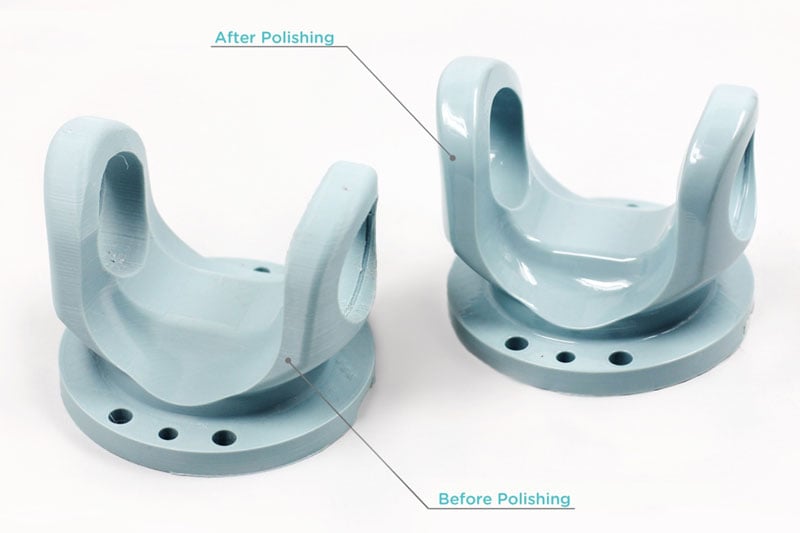

However, polycarbonate can be challenging to print due to its ability to contract if it is cooled too quickly, which can cause warping and shrinkage of the printed part. Controlling the ambient temperature, such as with a heated chamber, is one of the most critical factors when printing polycarbonate.

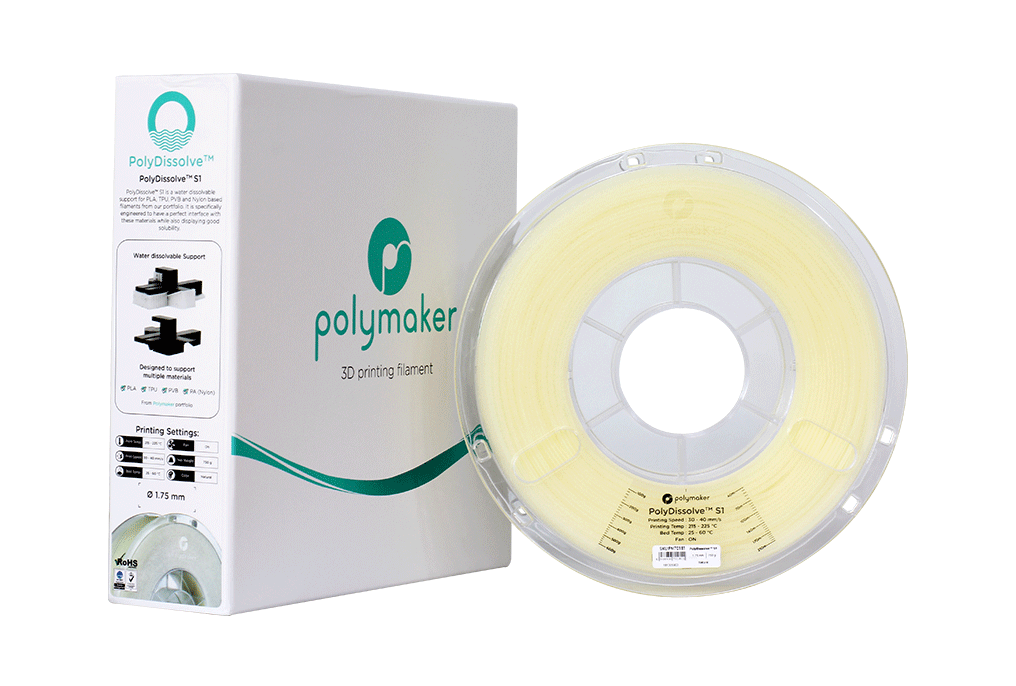

The MakerBot METHOD X 3D printer is the only printer in its price class with a heated chamber that reaches up to 110°C, letting the parts cool down gradually to minimize curling and warping. METHOD controls how fast a part cools down during the printing process, allowing it to print polycarbonate and other advanced materials more successfully than typical desktop 3D printers that only have a heated build plate. In addition, with the moisture sensitivity of PC materials, Polymaker recommends using a material caddy, such as the Polymaker PolyBox™, to safeguard them from precipitation in the environment. MakerBot METHOD™ users can also use the Material Drying mode on the METHOD X to remove moisture from the materials.

"Polycarbonate is often the choice for parts that function in demanding applications. Its mechanical properties, flame retardance, and chemical resistance also allow engineers to push the boundaries of their 3D printed parts and experiment with new geometries,” said Xiaofan Luo, PhD, President of Polymaker. “Anyone who is serious about printing polycarbonate knows that a heated chamber is essential for printing large and strong complex parts. METHOD is bringing industrial capabilities to a desktop machine, and we think its users will really benefit from the material properties our PC range offers.”

“With its up to 110°C heated chamber, METHOD is a powerful and unique 3D printer platform for printing advanced engineering materials. The availability of Polymaker’s PC materials on METHOD offers allows engineers to print polycarbonate parts that they previously had to outsource to more expensive industrial 3D printers,” said Johan-Till Broer, VP of Product Development, MakerBot. “We are seeing increased interest in industrial materials as engineers advance from simple prototyping to 3D printing end-use parts. We are thrilled that Polymaker has qualified its industrial range of PC materials for MakerBot LABS.”

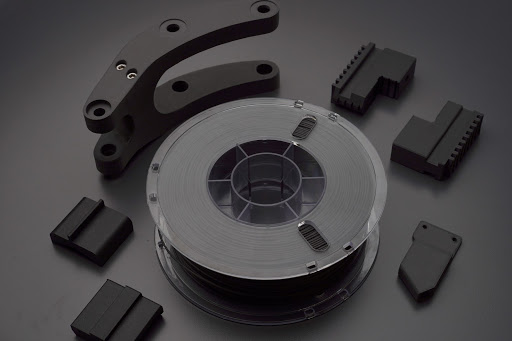

The addition of Polymaker polycarbonate materials brings the MakerBot LABS for METHOD portfolio of materials to nine and the total number of materials available on the METHOD platform to 19. The newly qualified polycarbonate materials from Polymaker include:

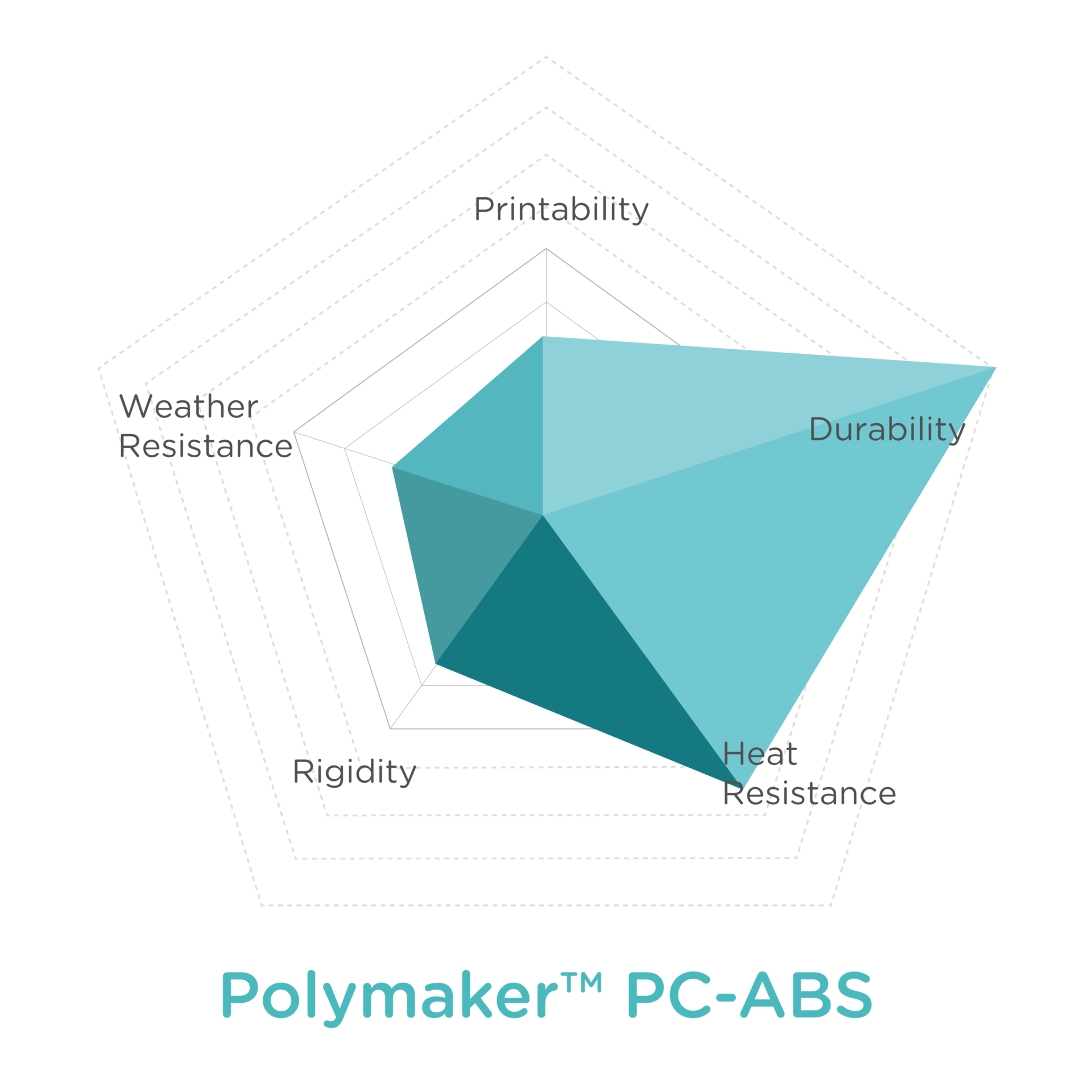

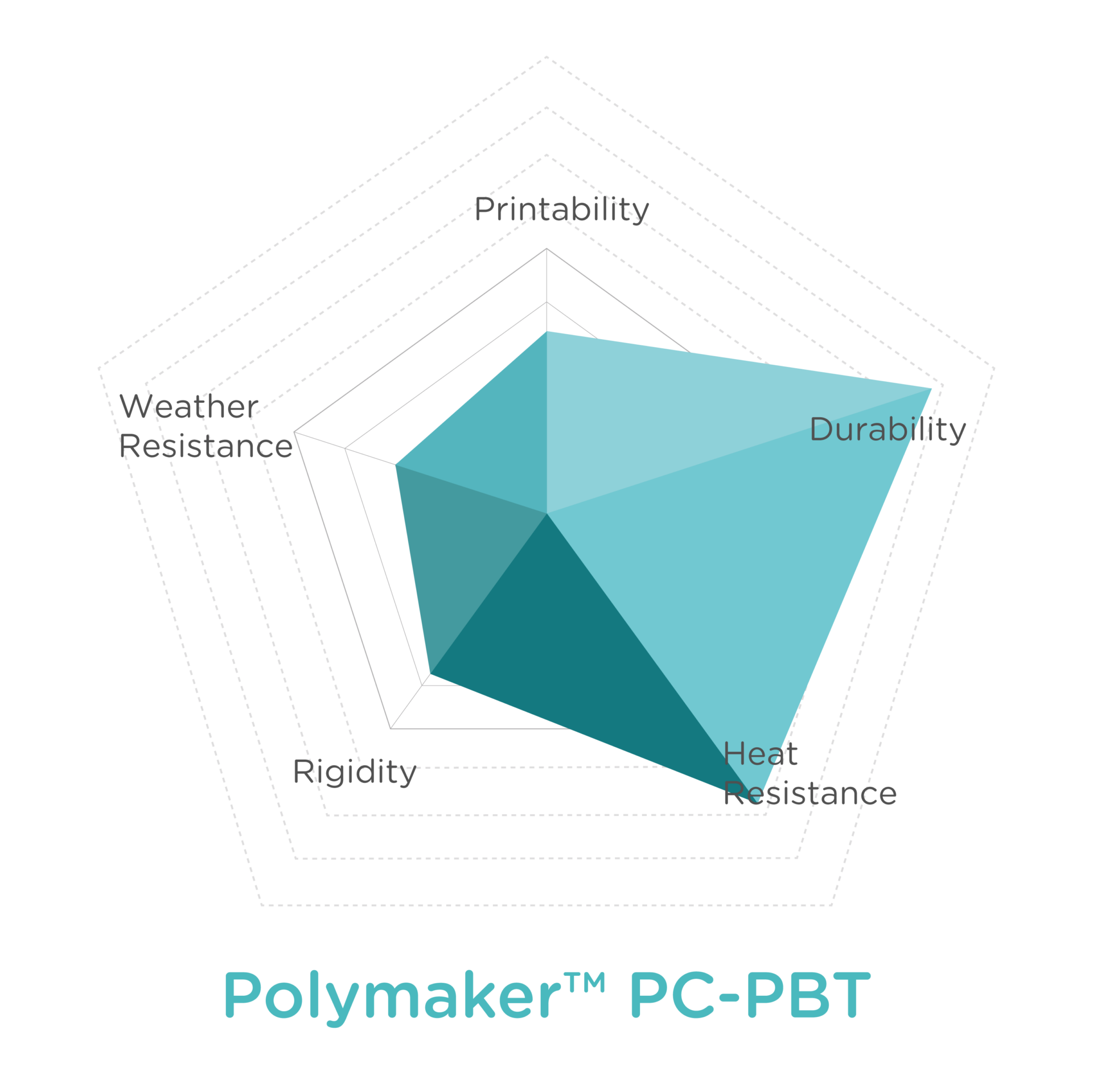

• Polymaker PC-PBT: This polymer blend combines the good chemical resistance of PBT (polybutylene terephthalate) with the strength and toughness of polycarbonate. Compared to PC resins and PC-ABS compounds, PC-PBT offers better resistance to chemicals, which enables printed applications where resistance to intermittent contact with fuels, oils, lubricants, or cleaners is necessary. It performs well under extreme circumstances, whether in contact with hydrocarbon-based chemicals or operating at subzero temperatures. Polymaker PC-PBT is a specialty material that maintains good toughness and natural ductile fracture behavior at low temperatures.

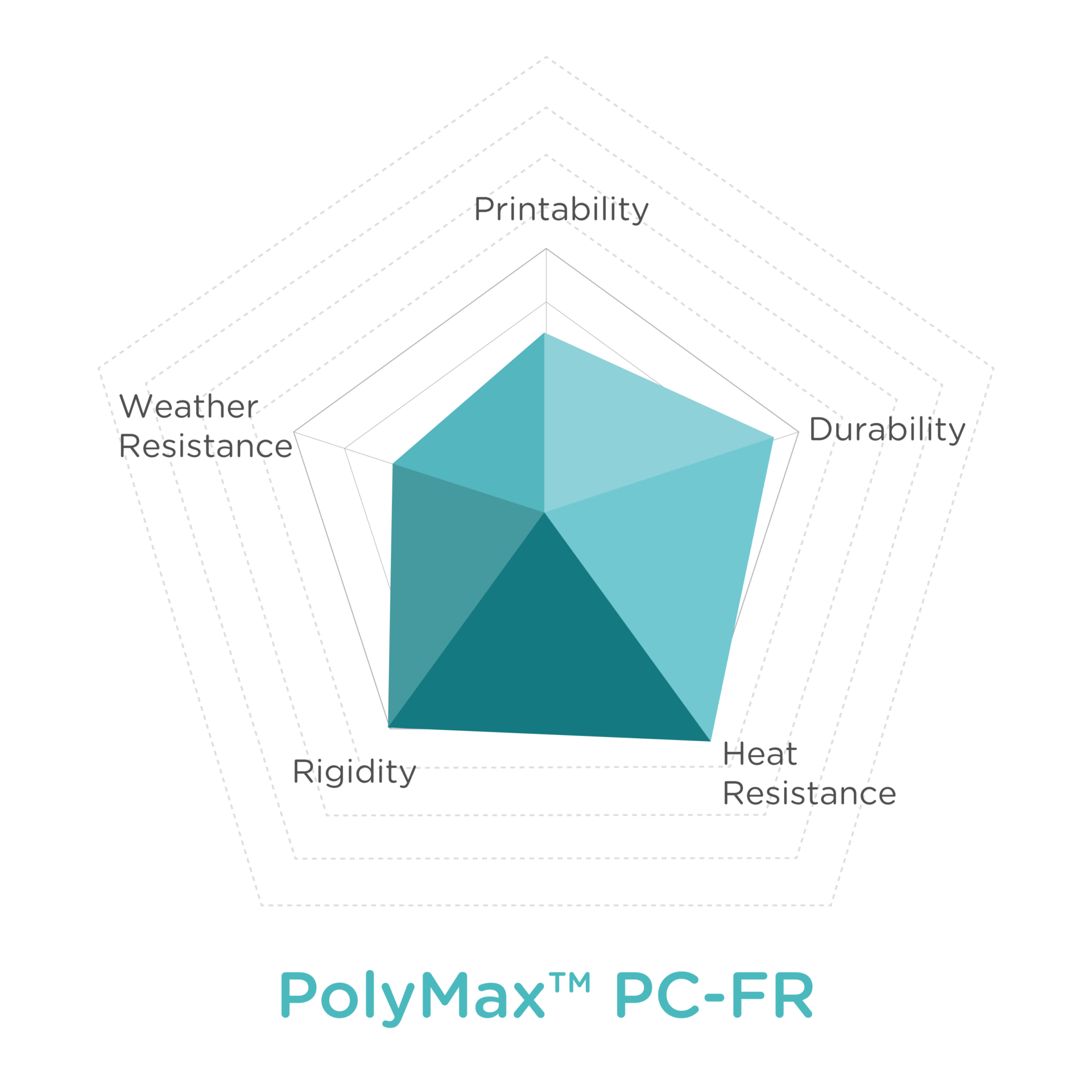

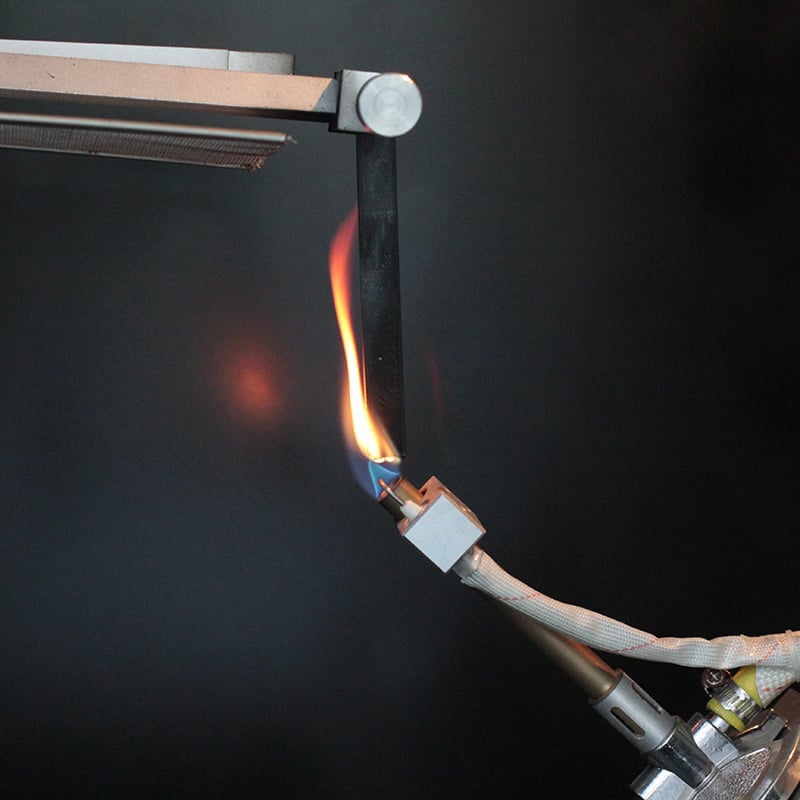

• PolyMax PC-FR: A flame retardant (FR) polycarbonate material, PolyMax PC-FR meets the UL-94 V0 standard, an important fire safety specification. The material displays excellent toughness, strength, and heat resistance, making it ideal for applications within the automotive, railway, and aerospace industries.

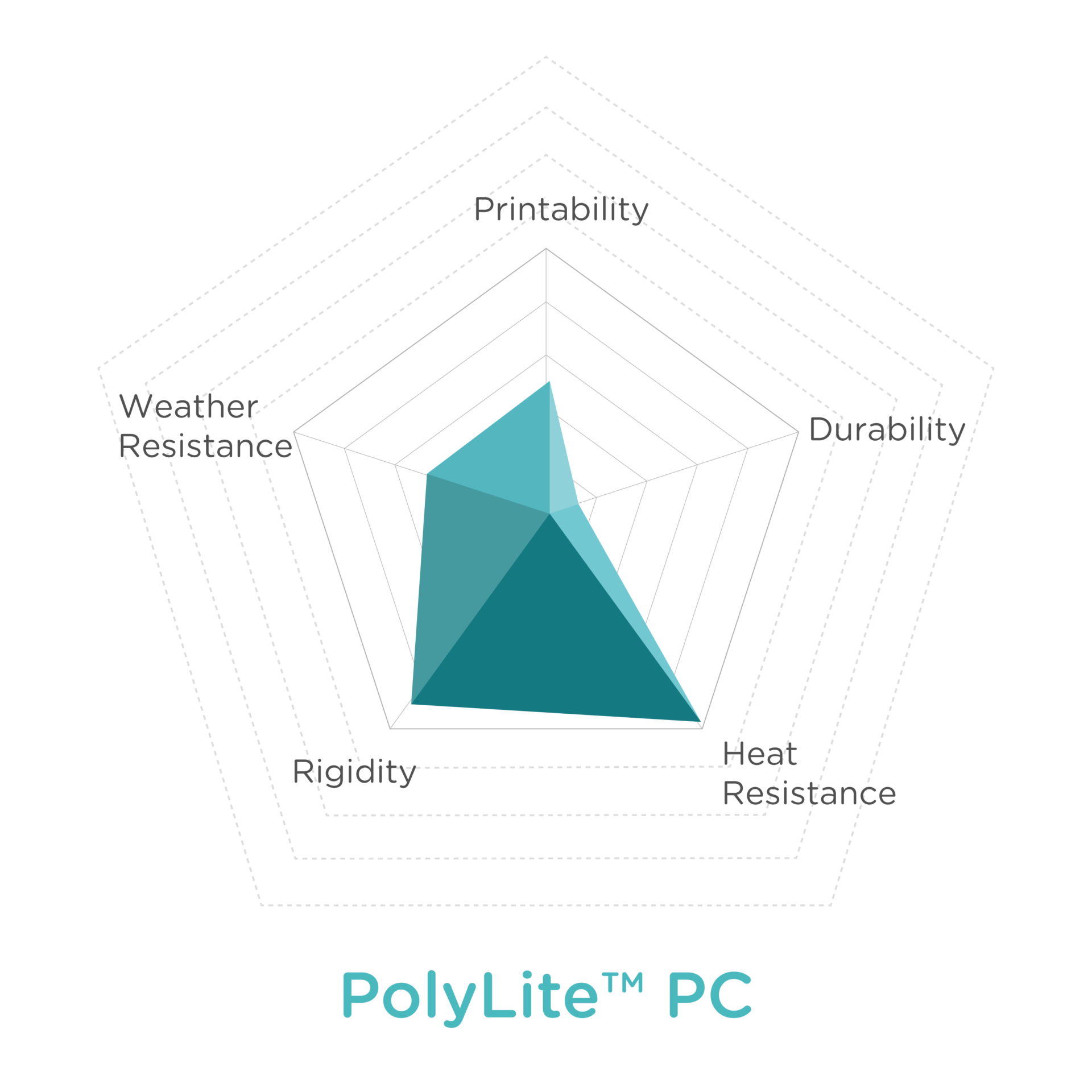

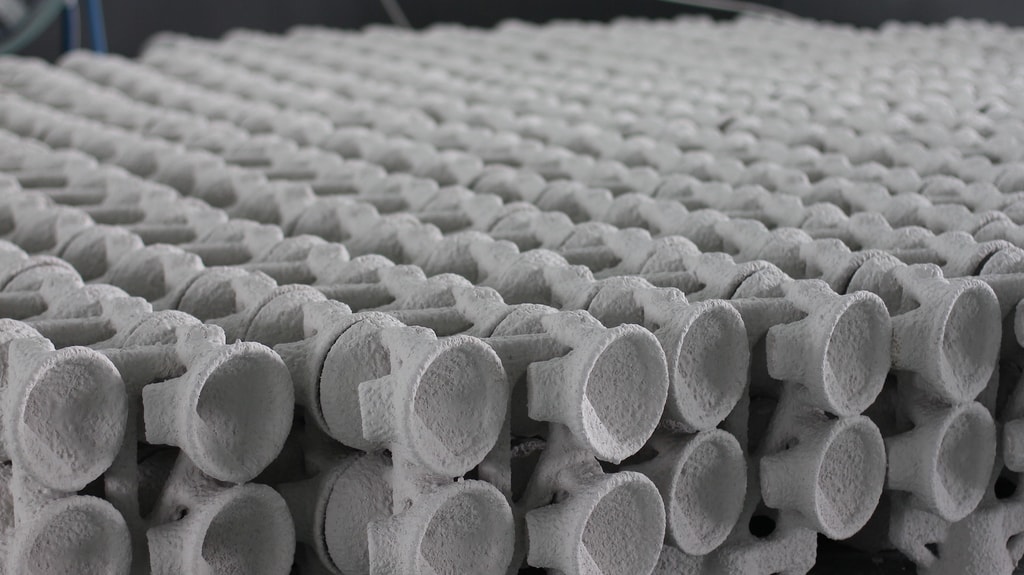

• PolyLite PC: PolyLite PC is produced using a polycarbonate resin specifically engineered for 3D printing. This material demonstrates a high modulus, making it ideal for applications that require good stiffness and light diffusion, such as outdoor light housings. PolyLite PC is available in transparent color, showing good optical clarity, rendering parts with an attractive crystal shine.

To further strengthen PC parts, Polymaker recommends annealing them right after the printing process to release the residual internal stress. The combination of METHOD’s heated chamber and annealing feature is designed to enable users to produce strong, manufacturing-grade parts. Polymaker materials can be purchased on the Polymaker site.

The MakerBot LABS extruder enables users to print with a wide variety of third-party materials on METHOD as an open materials platform, expanding the possibilities of applications. MakerBot offers a wide range of industrial materials through MakerBot LABS, and is continuing to identify additional advanced materials for the platform. Partners in the MakerBot LABS Materials Development Program include BASF 3D Printing Solutions, Jabil, Kimya, LEHVOSS Group, Mitsubishi Chemical, and Polymaker.

For more information, visit www.makerbot.com/method.