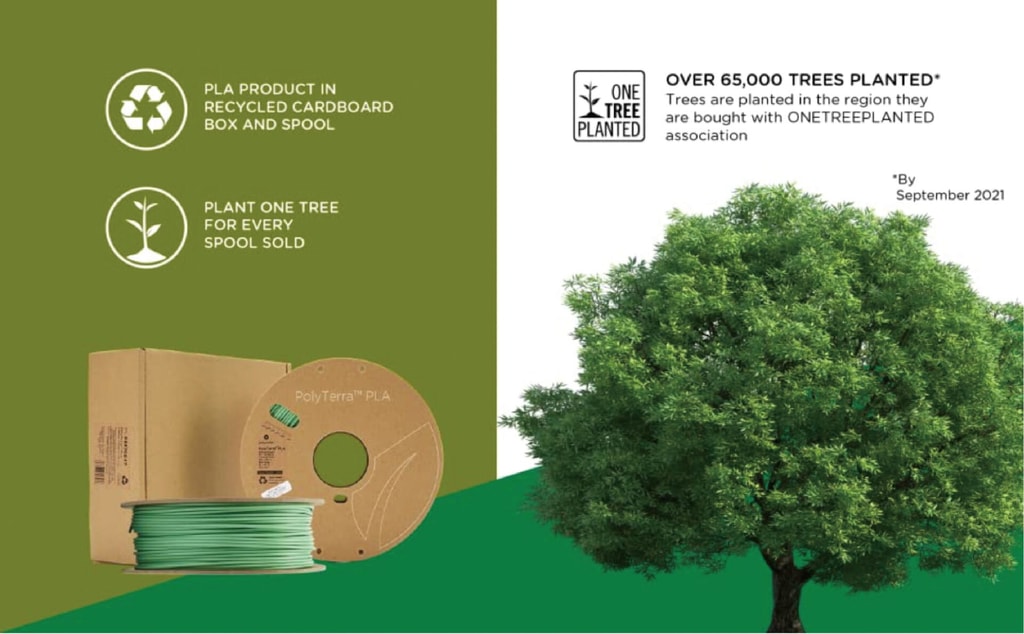

Polymaker transitions all filaments onto 100% recycled cardboard spools

Reducing plastic waste in 3D printing

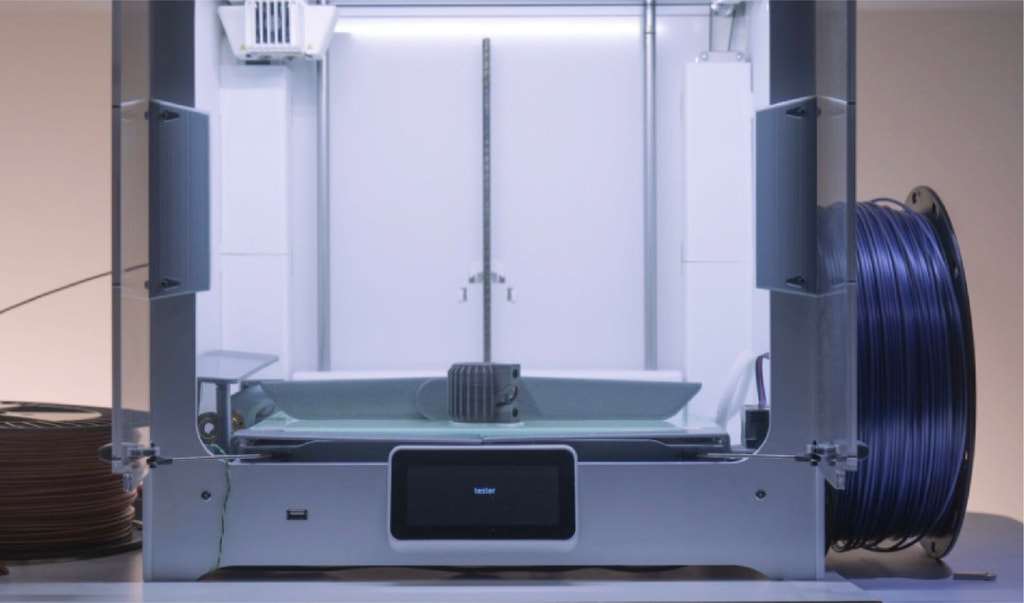

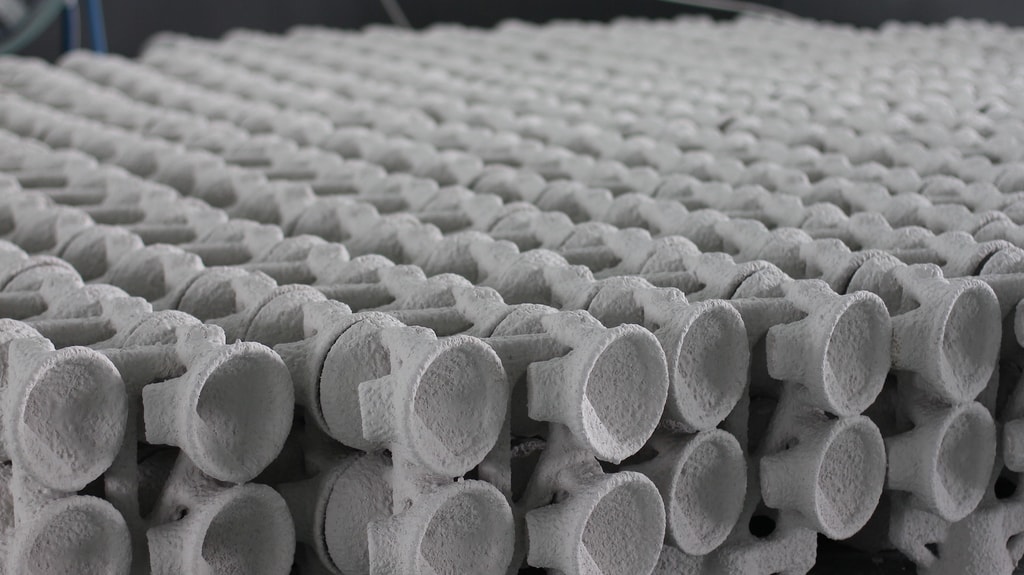

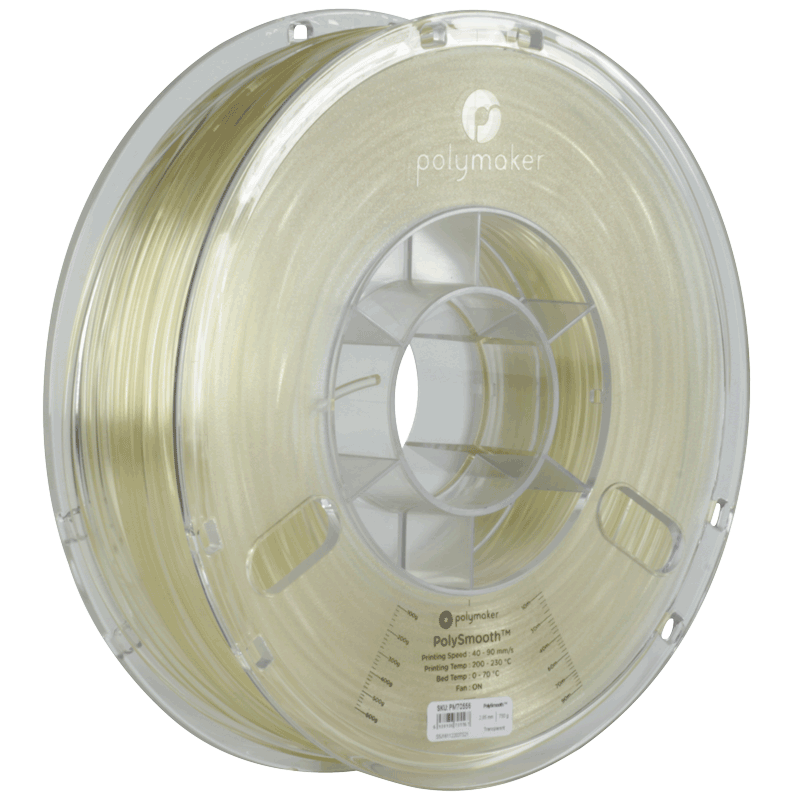

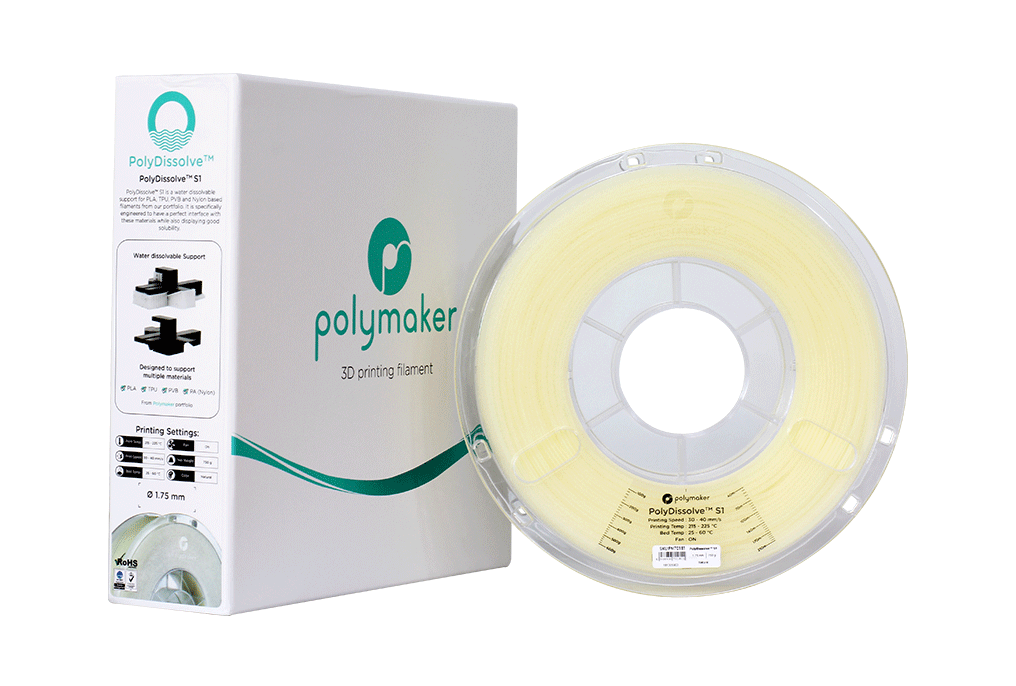

Polymaker, a leading producer of 3D printing materials announced today that filament production has ceased on all plastic spools. Moving forward, Polymaker will produce all filaments on a 100% recycled cardboard spools. This move aims to reduce plastic waste in 3D printing to create a more environmentally friendly product with packaging which can be easily recycled after use.

“Sustainability is a top priority for Polymaker, and I am glad to see our team taking this important initiative. We will continue the innovation to make all our products more sustainable.” – Dr. Xiaofan Luo – Founder of Polymaker

- The new cardboard spool features a thick, 4mm pressed and die cut cardboard spool face, glued onto a strip rolled section of cardboard tube. The thickness of the cardboard ensures the filament is well protected and the spool can roll very efficiently on all designs of spool holder both internally or externally mounted.

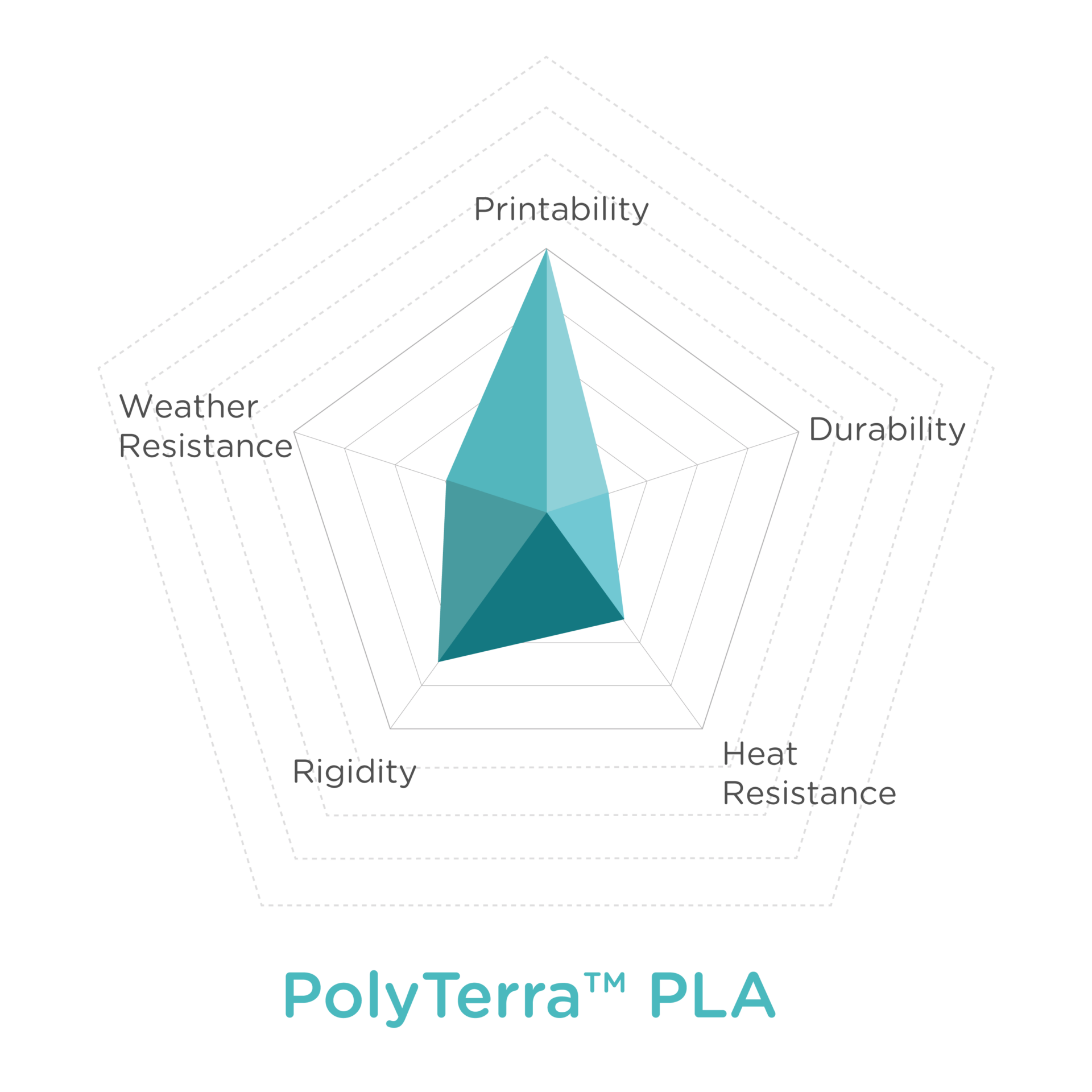

"Polymaker’s adoption of cardboard spools is in agreement with circular economy principles such as decoupling from petrochemical-based plastics and creating an after-use economy for recycled materials with their use of recycled fiber. Polymaker has long demonstrated these circular economy values, most recently with the launch of their PolyTerra™ filament, made from renewable biobased Ingeo™ biopolymer, with which they piloted the use of these cardboard spools. We are proud of our partnership with Polymaker and their progress towards environmentally friendly and sustainable practices in 3D printing." - Dan Sawyer - Natureworks

The new spool features a QR code which takes customers to the product information sheet on www.polymaker.com alongside: printing profiles, TDS, SDS and all other documentation relevant to the filament. The paper product information sheet will no longer be shipped inside the packaging further reducing waste.