September 18, 2020

Specialty Series

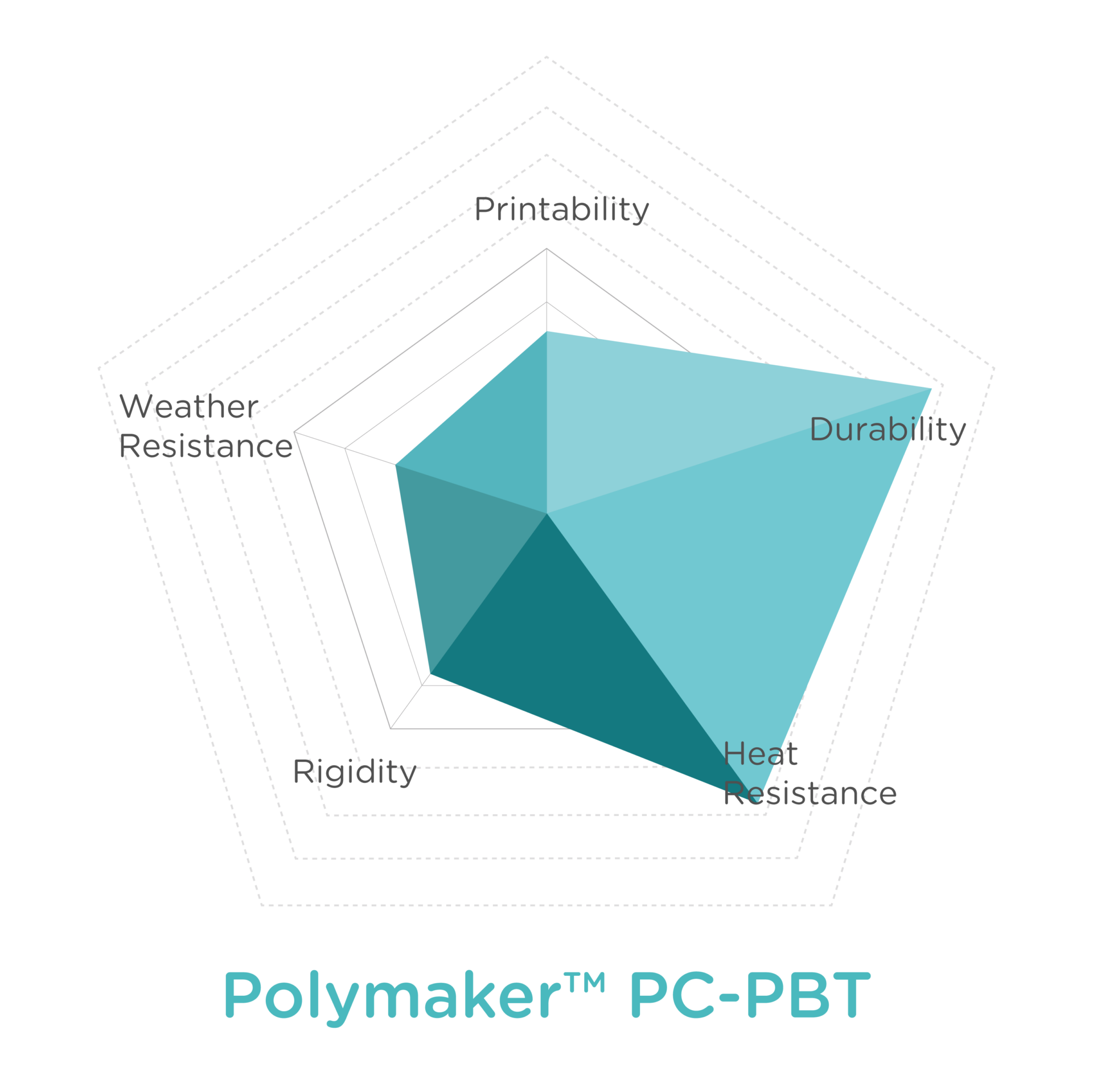

Polymaker™ PC-PBT is a PC/PBT polymer blend which offers good heat resistance, however, its key feature is toughness at low temperatures (-30˚C) where other plastics would become brittle. PC-PBT also features good chemical resistance and its characteristics make it ideal for automotive exterior parts such as bumpers, roof rail brackets or door handles.

* Please note that availability of certain SKUs may vary by location and not all products may be accessible at every reseller. We recommend contacting your local reseller for specific product availability in your region. You can also contact our regional sales team for more details.

Please fill in the form below or if you have other questions are not included in the form, please contact us through [email protected]. We will get back to you soon.

Please fill in the form below or if you have other questions are not included in the form, please contact us through [email protected]. We will get back to you soon.