With the increasing level of mechanization, agricultural drones are being used for various agricultural operations, such as large-scale crop spraying. There are several types of agricultural drones available on the market including 4 types: flight control system, power system, spraying system, and frame structure. The spraying system is the main application module of 3D printing technology in this field, including the pesticide tank, water pump, nozzles, and related sensors.

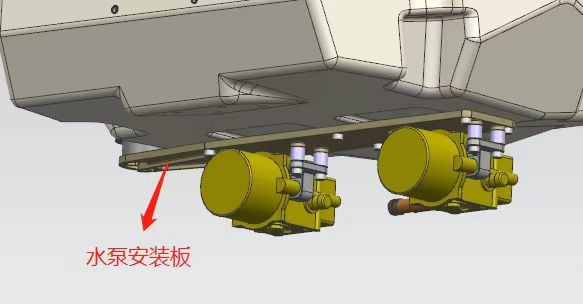

The pesticide tank of an agricultural drone stores the liquid for spraying, and during operation, the liquid is pumped out by the water pump. However, the vibration of the water pump affects the flight control system of the drone. Common methods use CNC aluminum plate processing to fix the water pump, but they have unavoidable disadvantages such as complex processes, poor corrosion resistance, low design flexibility, and lack of lightweight advantages. These factors can somewhat impact the production efficiency, payload capacity, and endurance of the drone.

By utilizing 3D printing technology, rapid prototyping and validation can be achieved, effectively solving the aforementioned problems and enabling small-batch production. After consideration, the manufacturer decided to collaborate with Amesos and Polymaker to create an additive manufacturing solution.

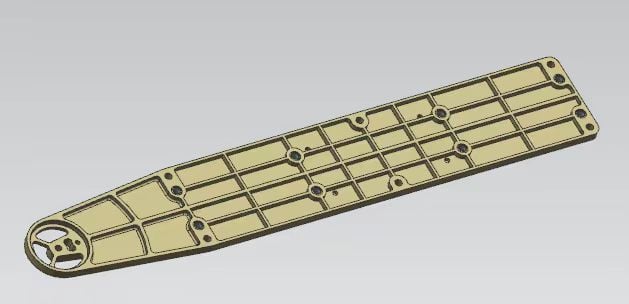

Amesos is primarily responsible for custom-designing water pump mounting plates that match the specific agricultural drone models to meet customer requirements. Within three days, four different versions were designed and tested, and the most suitable solution was selected and provided to the customer, successfully passing the installation tests. The next step was printing. The individual water pump on the mounting plate weighs around 400g, and the customer requires the installation of 2-3 water pumps. Therefore, the printed part needs to be made of a material that can withstand shocks and is not prone to breakage.

Polymaker is responsible for printing material selection. As a high-tech enterprise specializing in 3D printing materials, Polymaker began experimenting and comparing their diverse range of products as soon as they received the customer's requirements. Eventually, PolyMide™ PA612-CF material was chosen.

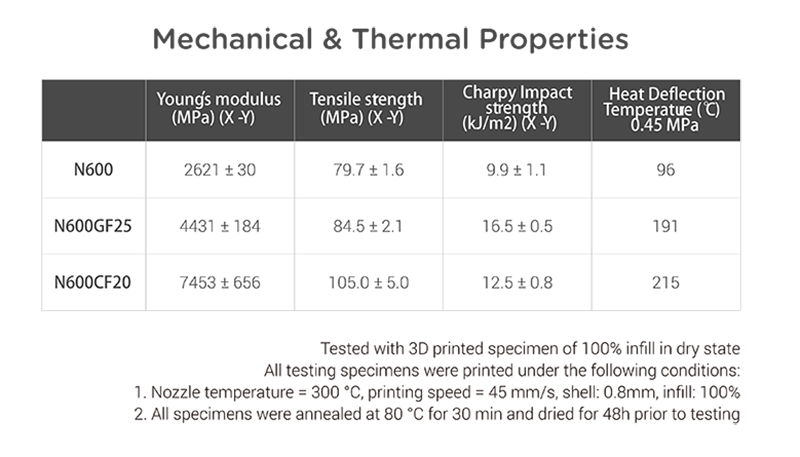

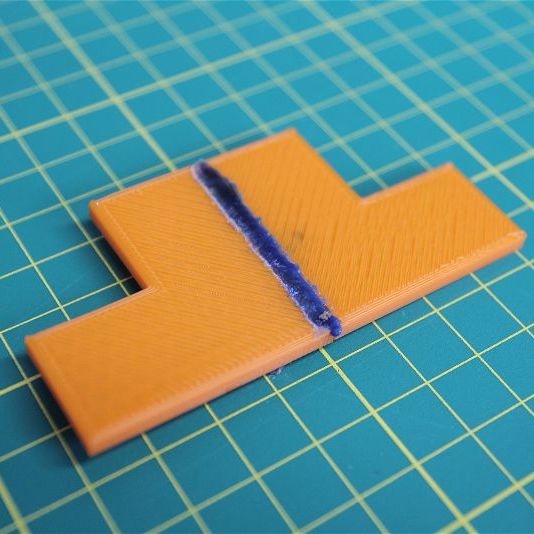

PolyMide™ PA612-CF is a carbon fiber-reinforced long-chain co-polyamide filament. Due to its chemical structure, this material has lower moisture sensitivity compared to PA6/66 and PA6-based materials, and better mechanical properties than PA12-based materials. Its advantages, such as high rigidity, toughness, and resistance to high temperatures, ensure that the water pump mounting plate printed with PolyMide™ PA612-CF is not affected by vibrations and maintains sufficient strength and stability. Additionally, its low water absorption allows for usage in humid environments, meeting the specific application requirements. Moreover, with the carbon fiber reinforcement and Warp-Free™ technology, products printed with PolyMide™ PA612-CF exhibit excellent dimensional stability, effectively prolonging the service life of the water pump mounting plate.

By employing 3D printing technology for the design and production of water pump mounting plates, the advantages of rapid prototyping, flexibility, and low cost are fully demonstrated. Manufacturers can quickly create prototypes, perform validation and necessary improvements, and immediately proceed with batch production and delivery. This process effectively shortens the product development cycle, enables the manufacturing of complex geometries and internal structures, and facilitates on-demand, high-efficiency production, greatly enhancing the economic benefits of production manufacturing.